Prefabricated polypropylene fiber sludge ceramsite concrete wall based on rough surface connection and its construction method

A polypropylene fiber, concrete wall technology, applied in the direction of walls, building components, building materials, etc., can solve the problems of lack of multi-channel fortification and anti-seismic mechanism, difficulty in meeting structural ductility design requirements, high energy and raw material consumption, etc. Achieve the effect of solving high prefabrication precision requirements, excellent ductility design, and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

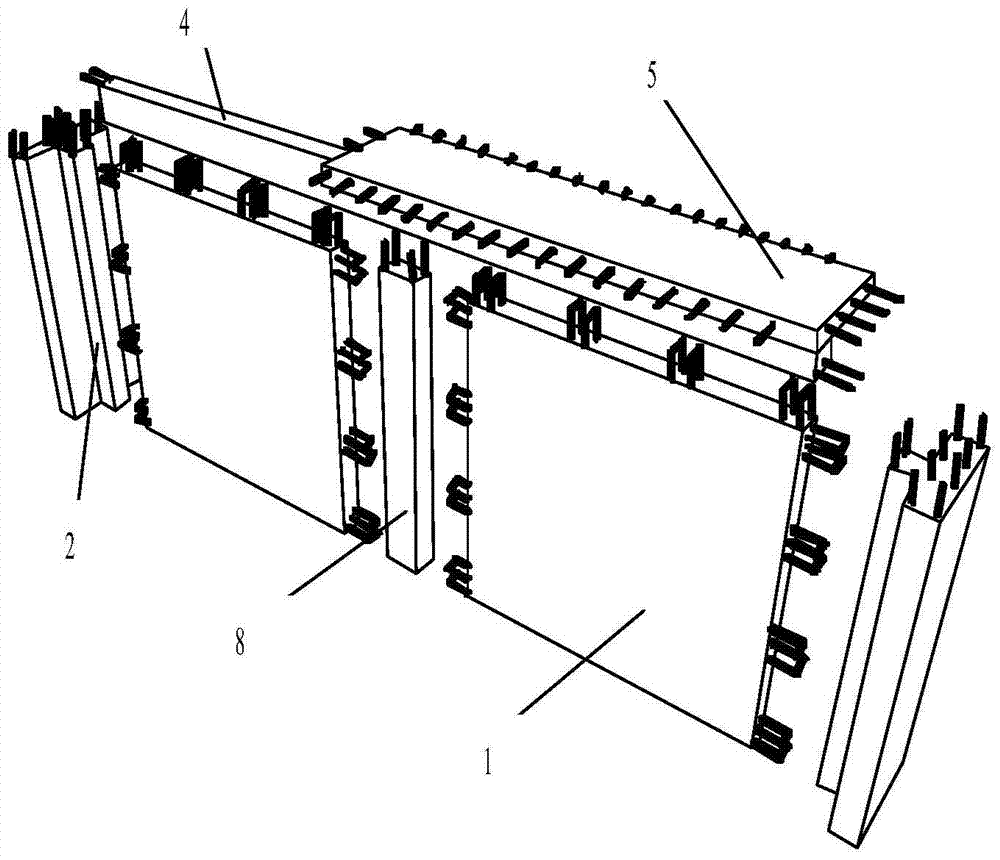

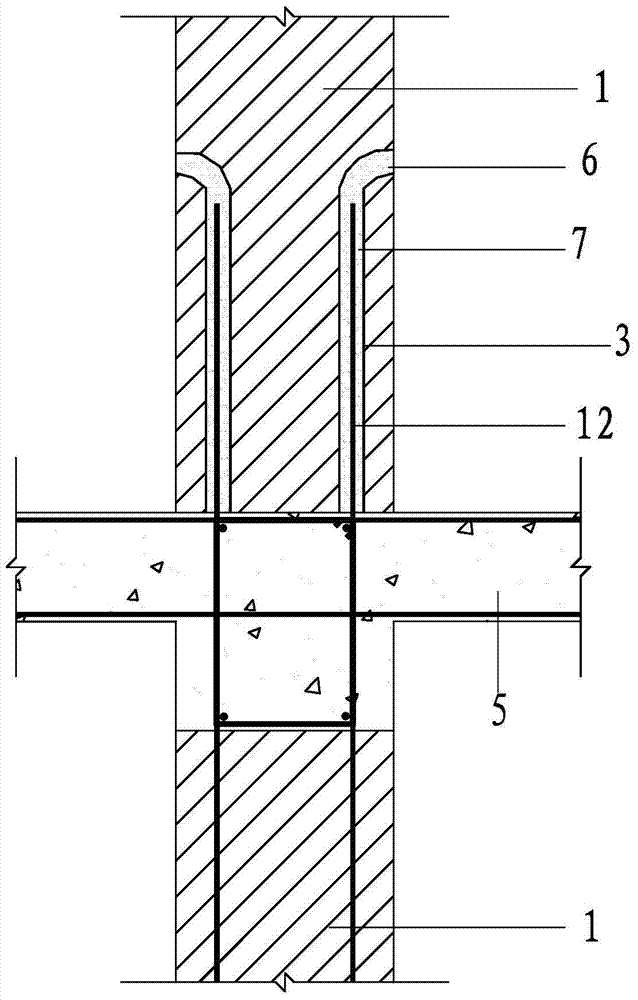

[0036] Such as figure 1 , figure 2 and image 3 Shown, the prefabricated polypropylene fiber sludge ceramsite concrete wall body that the present invention connects based on rough surface, comprises:

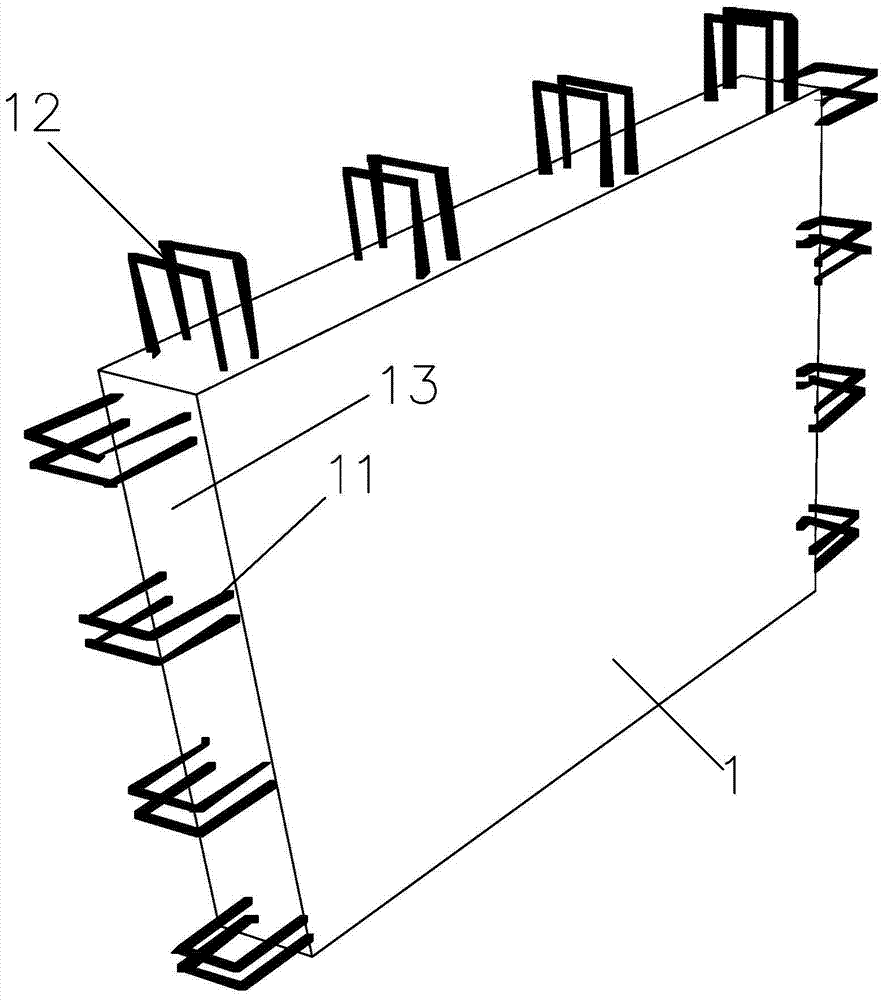

[0037] The prefabricated wallboard 1 has rough surfaces 13 on its left and right sides, and built-in horizontal steel bars 11 and vertical steel bars 12; the horizontal steel bars 11 and the vertical steel bars 12 are in the form of double bars in the left, right and front and back directions of the prefabricated wallboard 1, Optimized as a "well" shape, such as figure 2 and image 3 As shown, four horizontal steel bars 11 and four vertical steel bars 12 form a unit, and a prefabricated wall panel 1 has a plurality of units evenly crossed in order.

[0038] Such as Figure 4 As shown, a preferred size parameter of the prefabricated wallboa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com