A method for non-destructive determination of steel corrosion product characteristics based on bp neural network

A BP neural network and neural network technology, applied in the field of predicting actual steel corrosion products, to achieve the effect of convenient data collection, reduced test cost and operation difficulty, and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

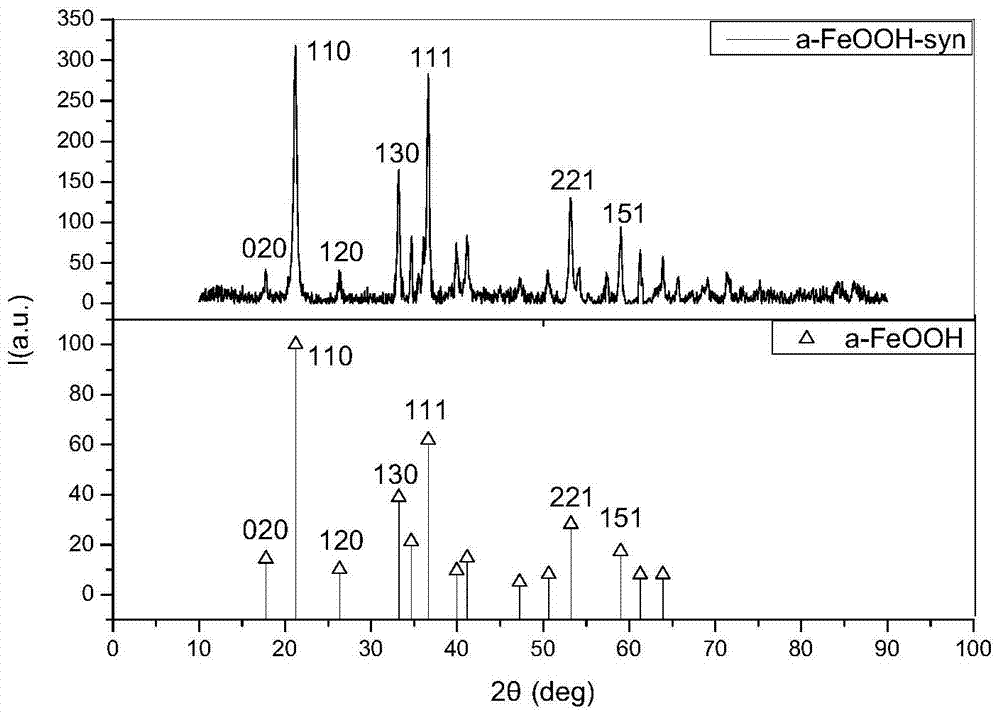

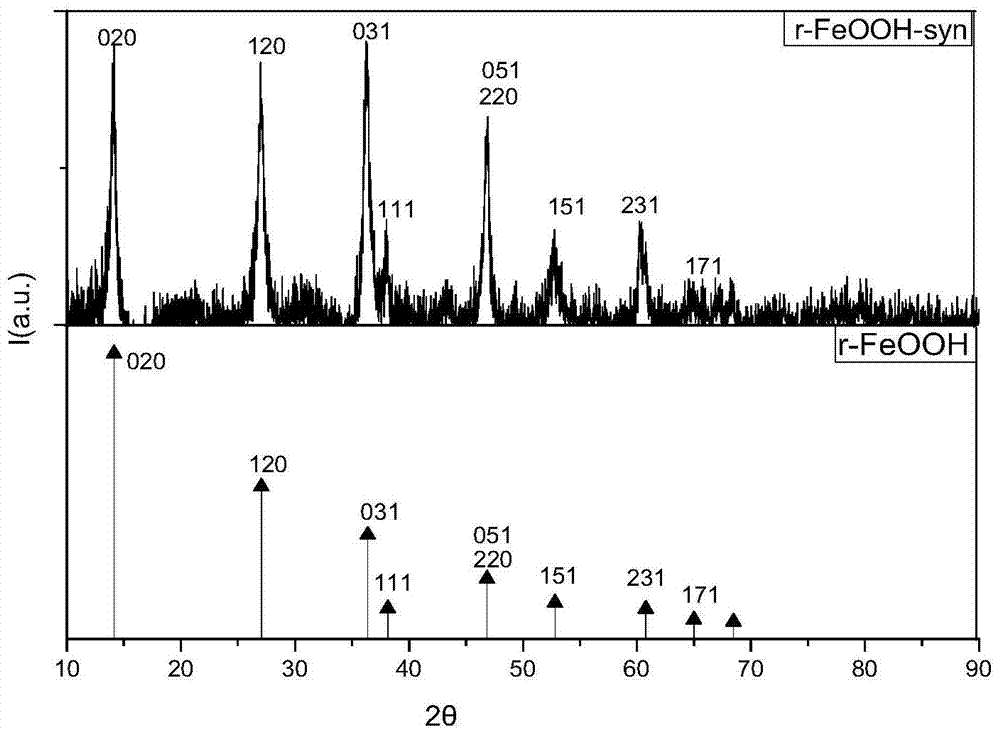

Embodiment Construction

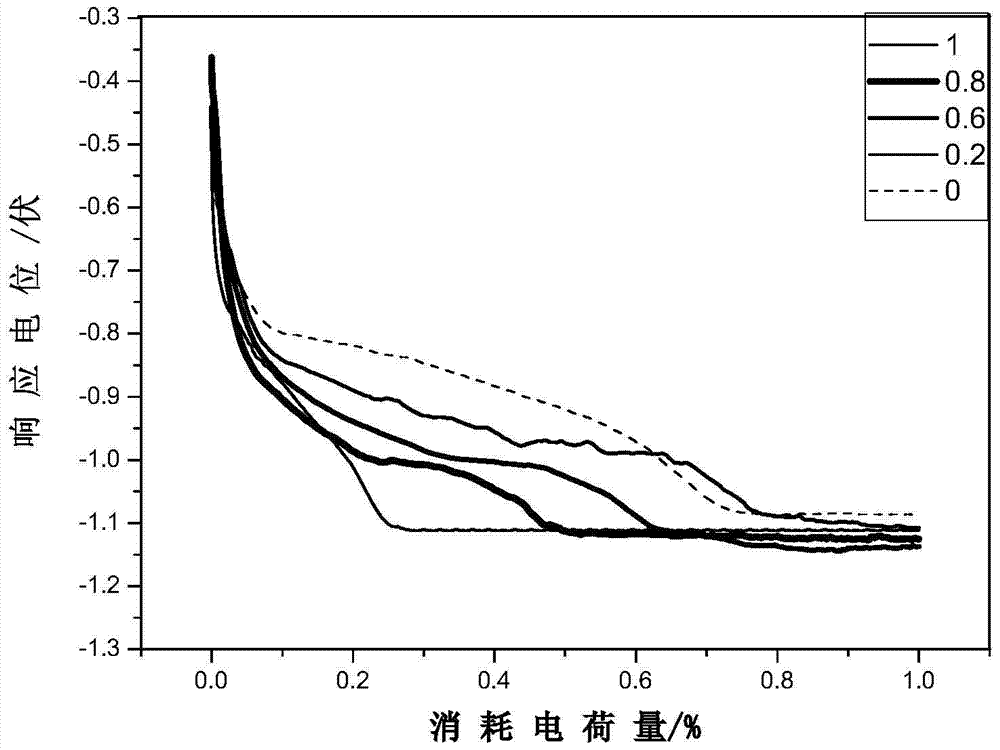

[0050] The electrochemical experimental device includes a sample table, a three-electrode system: a sample (working electrode), a reference electrode (SCE electrode), an auxiliary electrode (platinum electrode) and an electrochemical workstation. When the electrochemical test device is connected to the sample section, the traditional three-electrode system is used. The preparation of the working electrode includes the following steps: take a 1cm*1cm stainless steel mesh, stick it on one side with a double-sided conductive adhesive, and put a certain mass of mixed powder Press it in from the other side, and finally seal the edge with resin, so that the working surface is a sample plane of 1cm*1cm, and finally solder the wires on the conductive glue, and seal the welding place with resin. The auxiliary electrode is a platinum electrode, the reference electrode is a saturated calomel electrode (SCE); connect the workstation, apply a constant current of 2.5mA / g-7.5mA / g, the electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com