Method for improving delicate flavor of peptide by using beta-cyclodextrin

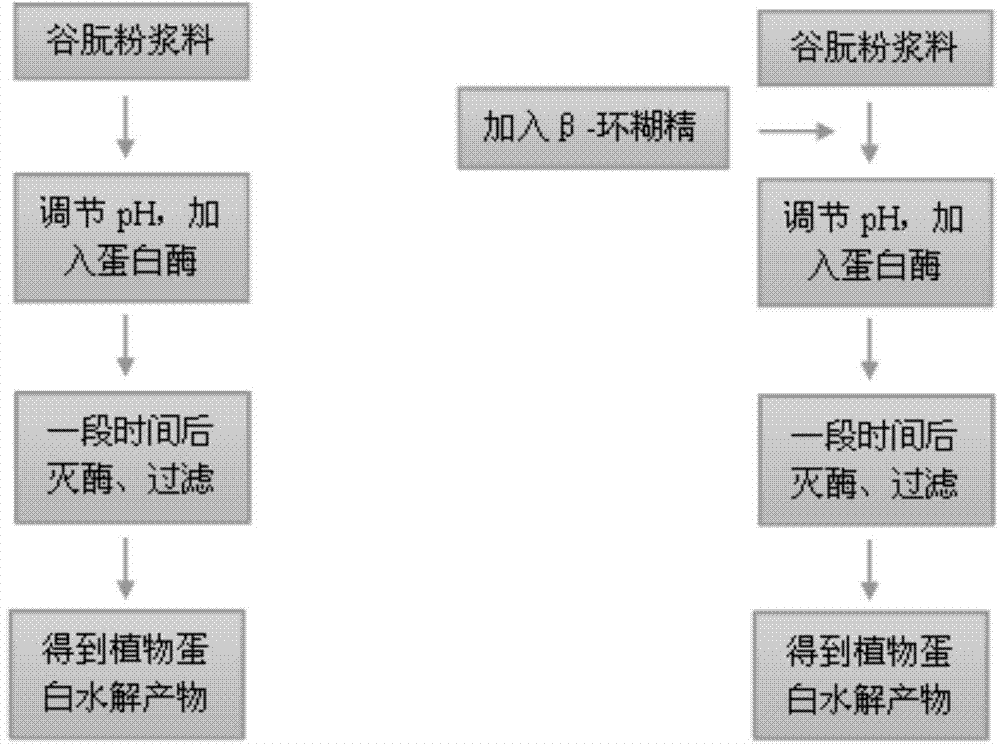

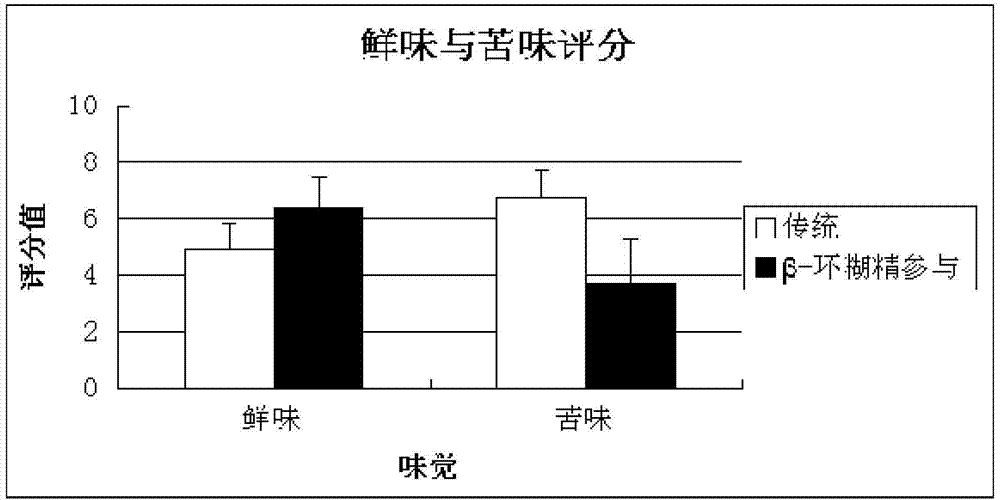

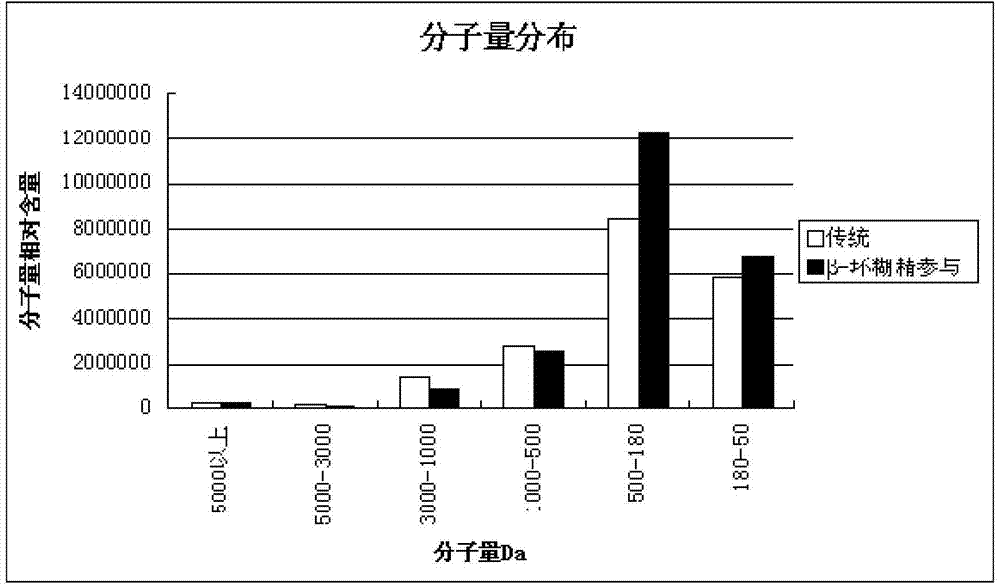

A cyclodextrin and flavor peptide technology, which is applied in the field of food processing, can solve the problems of flavor enhancement of flavor peptides, achieve strong umami taste, ensure protein yield and nutritional value, and high protein yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Dissolve β-cyclodextrin in 100ml of water to prepare 0.035mol / L β-cyclodextrin solution. Pass the gluten powder through a 100-mesh sieve, then dissolve 4g gluten powder in the β-cyclodextrin solution, adjust the pH of the solution to 7.0 with 0.5mol / L NaOH solution to obtain a gluten powder slurry, and heat up to 50°C for 10 minutes insulation.

[0026] (2) 0.6 g of neutral protease and 0.4 ml of flavor protease were dissolved in 10 mL of 0.2 mol / L phosphate buffer solution with a pH of 7.0 to obtain neutral protease dilution and flavor protease dilution.

[0027] (3) Take 1ml of neutral protease and 1ml of flavored protease, mix them in the gluten slurry, shake in a constant temperature water bath at 50°C for 8 hours.

[0028] (4) Put the enzymolysis solution in a boiling water bath for 10 minutes to inactivate the enzyme, centrifuge at 3500 r / min for 15 minutes, filter, and take the supernatant, which is the gluten-derived flavor peptide that β-cyclodextrin parti...

Embodiment 2

[0030] (1) Dissolve β-cyclodextrin in 100ml of water to prepare 0.018mol / L β-cyclodextrin solution. Pass the gluten powder through a 100-mesh sieve, then dissolve 4g gluten powder in the β-cyclodextrin solution, adjust the pH of the solution to 7.0 with 0.5mol / L NaOH solution to obtain a gluten powder slurry, and heat up to 50°C for 10 minutes insulation.

[0031] (2) 0.6 g of neutral protease and 0.4 ml of flavor protease were dissolved in 10 mL of 0.2 mol / L phosphate buffer solution with a pH of 7.0 to obtain neutral protease dilution and flavor protease dilution.

[0032] (3) Take 1ml neutral protease diluent and 1ml flavored protease diluent respectively, mix them evenly in the gluten slurry, shake in a constant temperature water bath at 50°C for 8h.

[0033] (4) Put the enzymolysis solution in a boiling water bath for 10 minutes to inactivate the enzyme, centrifuge at 3500 r / min for 15 minutes, filter, and take the supernatant, which is the gluten-derived flavor peptide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com