Preparation of flaky cross-linked sodium hyaluronate hydrogel

A technology of cross-linking hyaluronic acid and sodium hyaluronate, which is applied in the field of medical biomaterials, can solve the problems of insufficient strength and toughness of sodium hyaluronate hydrogel, and achieve an effect that is beneficial to growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

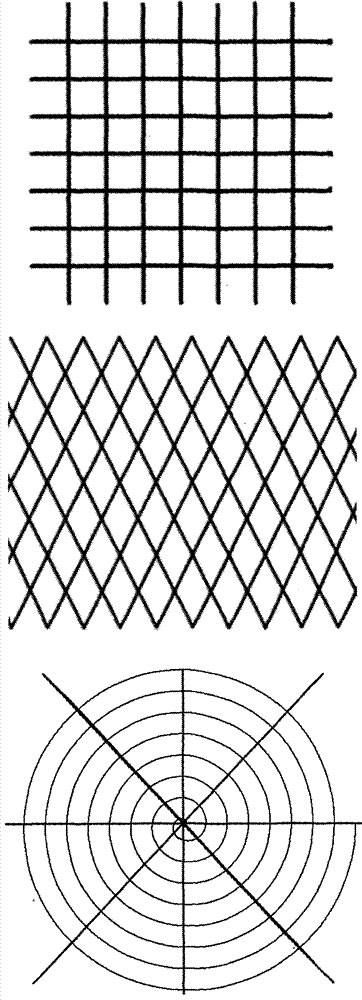

Image

Examples

Embodiment 1

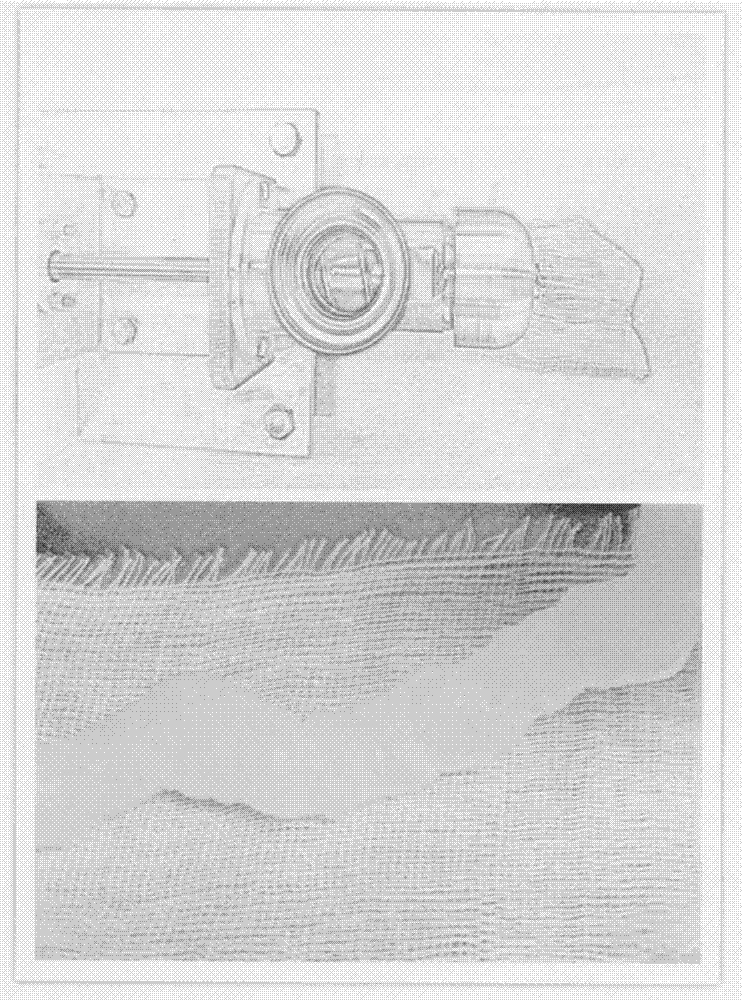

[0029] Take 10 grams of sodium hyaluronate (molecular weight is about 3×10 6 ) In a 250ml beaker, 500 μl of 1,4 butanediol diglycidyl ether (BDDE) was dissolved in a 250ml beaker of 40ml 1% sodium hydroxide, and the lye mixed with BDDE was poured into the hyaluronic acid Sodium in a beaker. After mixing thoroughly, enter the figure 2 machine, extruding the gel into strips on the grid. The thickness of the gel is 1mm, and the flake gel is placed flat on the bottom of the flat-bottomed stainless steel tray, in a water bath at 50°C, for 2 hours, and taken out and rolled four times during this process. Remove the tray and rinse it under pure running water for 2 hours. After draining, place it in a vacuum drying oven at 50°C for 3 hours. Phosphate-buffered saline (0.276g Na in 1000ml water 2 HPO 4 .2H 2 O; 0.0395 g NaH 2 PO 4 ..4H 2 O,; 8.476N a CL, pH value 7.3) soaked for 3 hours, the swelling degree reached 50%. Cut the hydrogel into a 30mm×50mm rectangle and plasti...

Embodiment 2

[0031] Take 10 grams of sodium hyaluronate (molecular weight is about 3×10 6 ) In a 250ml beaker, 1000 μl of 1,2,7,8 octane was dissolved in 40ml of 1% sodium hydroxide in a 250ml beaker, and the lye mixed with BDDE was poured into the beaker with sodium hyaluronate. The rest are the same as above. This product is more elastic and less viscous.

Embodiment 3

[0033] Take 10 grams of sodium hyaluronate (molecular weight is about 3×10 6 ) In a 250ml beaker, 500 μl of 1,2,7,8 octane was dissolved in 40ml of 1% sodium hydroxide in a 250ml beaker, and the lye mixed with BDDE was poured into the beaker with sodium hyaluronate. The rest are the same as above. This product is less elastic and more viscous.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com