A method for harmless debromination of bromine-containing plastic waste

A harmless and plastic technology, applied to the removal of solid waste, etc., can solve the problems of harsh reaction conditions, high equipment material requirements, corrosion of reaction equipment, etc., achieve mild reaction conditions, improve debromination efficiency, and be easy to control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

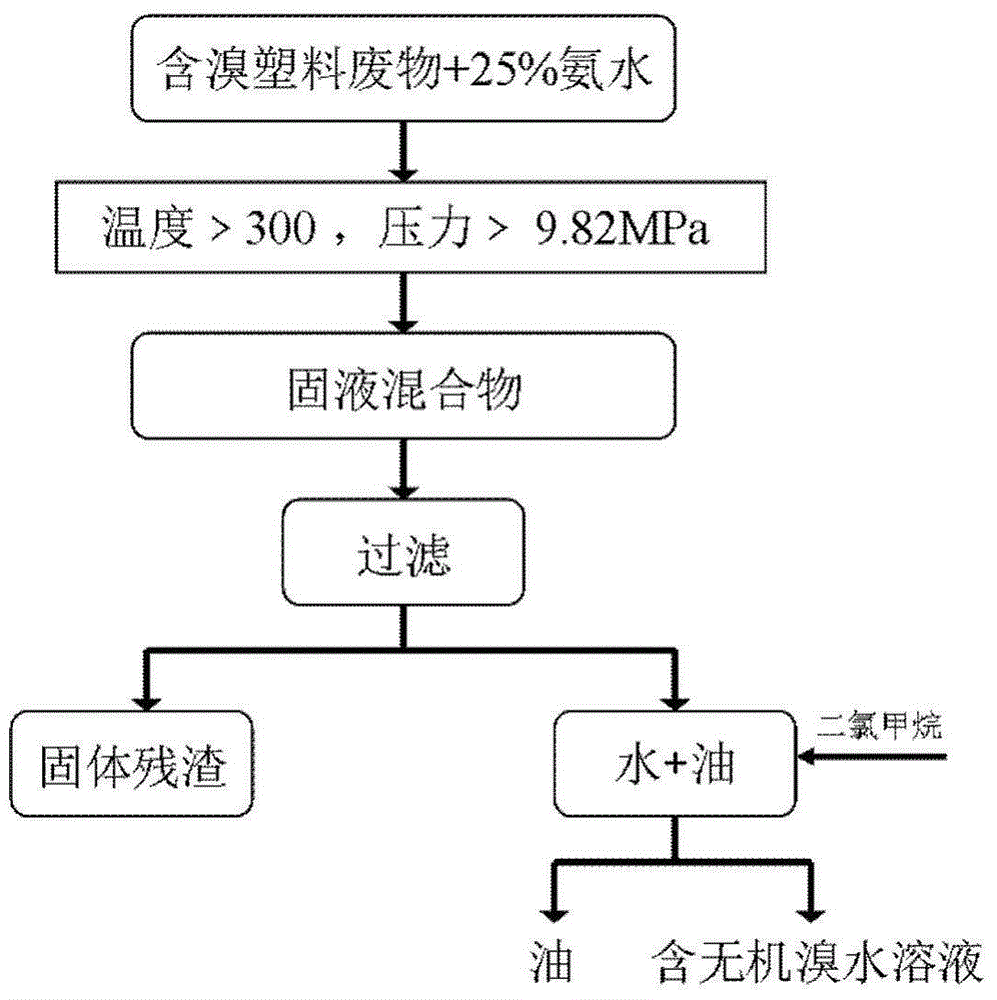

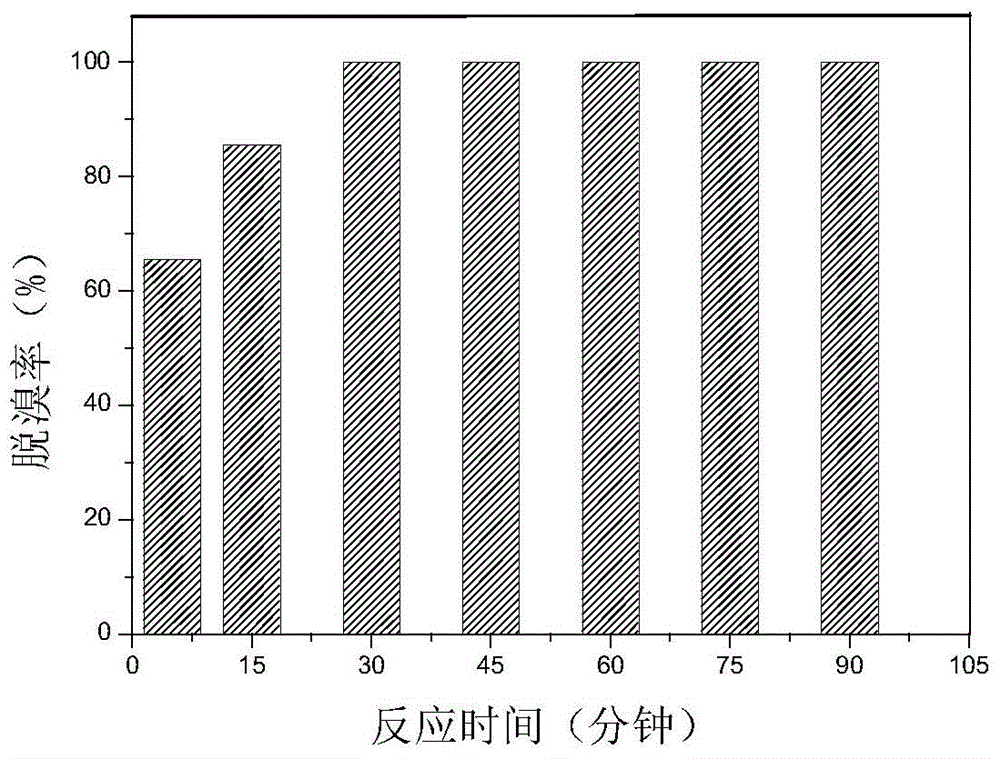

[0024] Such as figure 1 with figure 2 As shown, first cut the waste computer plastic case containing bromine 14.8% (w / w%) into a shape of about 3cm × 3cm, put 5 grams of it in a high-temperature and high-pressure reactor with a volume of 200 milliliters, and then pour it into the reactor Add 75 milliliters of aqueous ammonia with a concentration of 25%, seal the reactor, heat up to 300° C., control the pressure at 9.82 MPa, and start timing. Heating was stopped after 10 min of reaction. When the temperature of the reactor is lowered to room temperature, the reactor is opened, and the reaction product is transferred to a centrifuge tube. After centrifugation, the filtrate is ultrasonically extracted with dichloromethane for 20 minutes, and the oil phase product is separated by shaking, and then the water is removed by anhydrous sodium sulfate. , Remove dichloromethane with a rotary evaporator to obtain oil, and the evaporated dichloromethane extractant is recovered and recyc...

Embodiment 2

[0026] Such as figure 1 with figure 2 As shown, first cut the waste computer plastic casing containing bromine 14.8% (w / w%) into a shape of about 3cm×3cm, put 5 grams of it in a high-temperature and high-pressure reactor with a volume of 200 milliliters, and then pour it into the reactor. Add 75 milliliters of aqueous ammonia with a concentration of 25%, seal the reactor, heat up to 300° C., control the pressure at 9.82 MPa, and start timing. Heating was stopped after 15 minutes of reaction. When the temperature of the reactor is lowered to room temperature, the reactor is opened, and the reaction product is transferred to a centrifuge tube. After centrifugation, the filtrate is ultrasonically extracted with dichloromethane for 20 minutes, and the oil phase product is separated by shaking, and then the water is removed by anhydrous sodium sulfate. , Remove dichloromethane with a rotary evaporator to obtain oil, and the evaporated dichloromethane extractant is recovered and ...

Embodiment 3

[0028] Such as figure 1 with figure 2 As shown, first cut the waste computer plastic casing containing bromine 14.8% (w / w%) into a shape of about 3cm×3cm, put 5 grams of it in a high-temperature and high-pressure reactor with a volume of 200 milliliters, and then pour it into the reactor. Add 75 milliliters of aqueous ammonia with a concentration of 25%, seal the reactor, heat up to 300° C., control the pressure at 9.82 MPa, and start timing. Heating was stopped after 30 minutes of reaction. When the temperature of the reactor is lowered to room temperature, the reactor is opened, and the reaction product is transferred to a centrifuge tube. After centrifugation, the filtrate is ultrasonically extracted with dichloromethane for 20 minutes, and the oil phase product is separated by shaking, and then the water is removed by anhydrous sodium sulfate. , Remove dichloromethane with a rotary evaporator to obtain oil, and the evaporated dichloromethane extractant is recovered and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com