Radial Forging Strain-Induced Semi-Solid Extrusion Process for Waveguides

A semi-solid extrusion and radial forging technology, applied in the direction of metal processing equipment, etc., can solve the problems of casting and forming waveguide grains, such as coarse grains, shrinkage porosity, and poor mechanical properties of products, to achieve good internal structure and overall performance, microscopic Microstructure grains, good mechanical properties of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

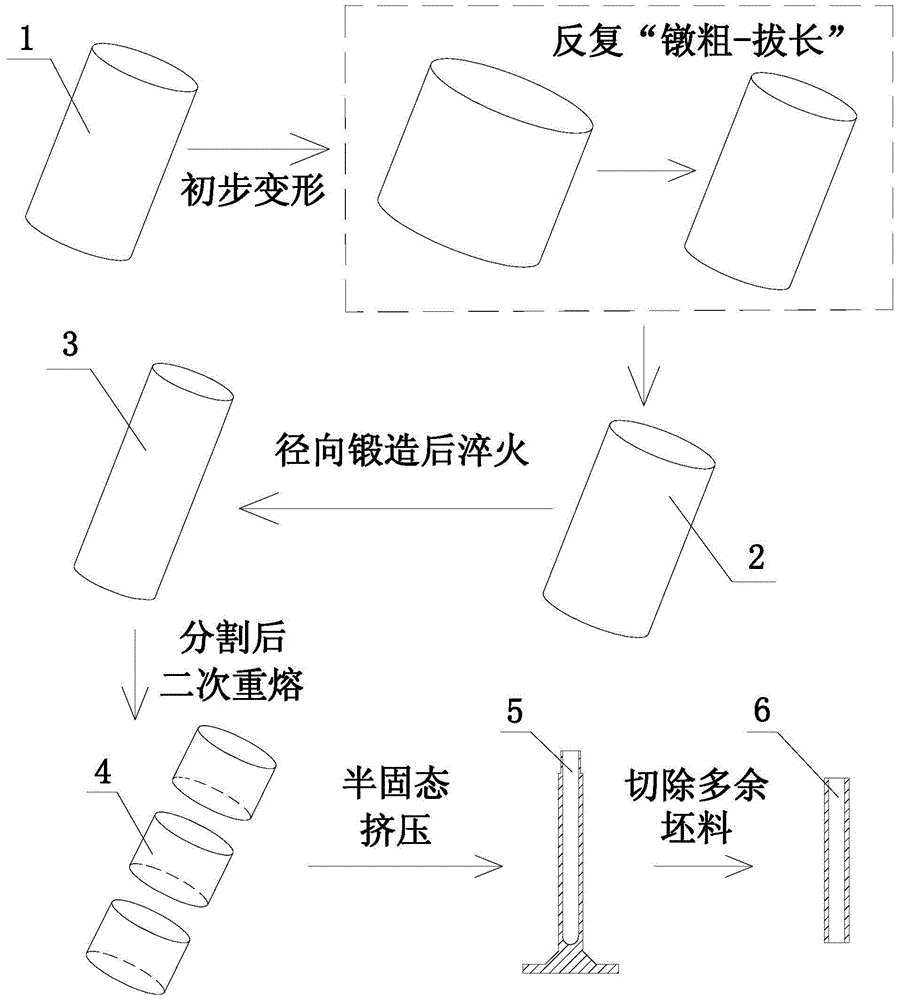

[0024] refer to figure 1 , a radial forging strain-induced semi-solid extrusion process for waveguides, including the following steps:

[0025] 1) Preliminary deformation of the bar: first prepare the metal bar 1 made of copper alloy, aluminum alloy, or magnesium alloy for forming the waveguide; then preheat the metal bar 1 and perform repeated upsetting and elongation to Obtain a distorted metal rod 2 that stores distortion energy;

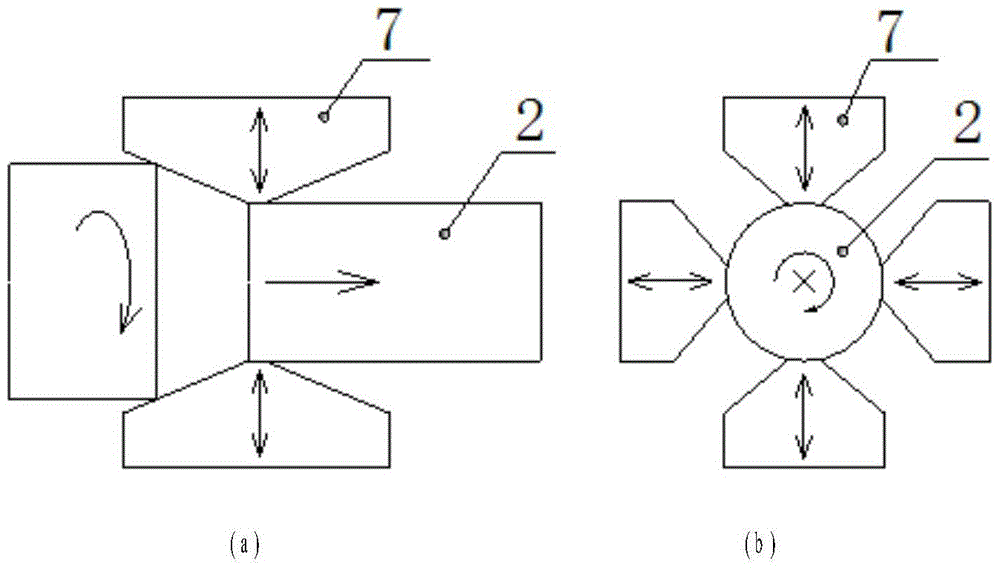

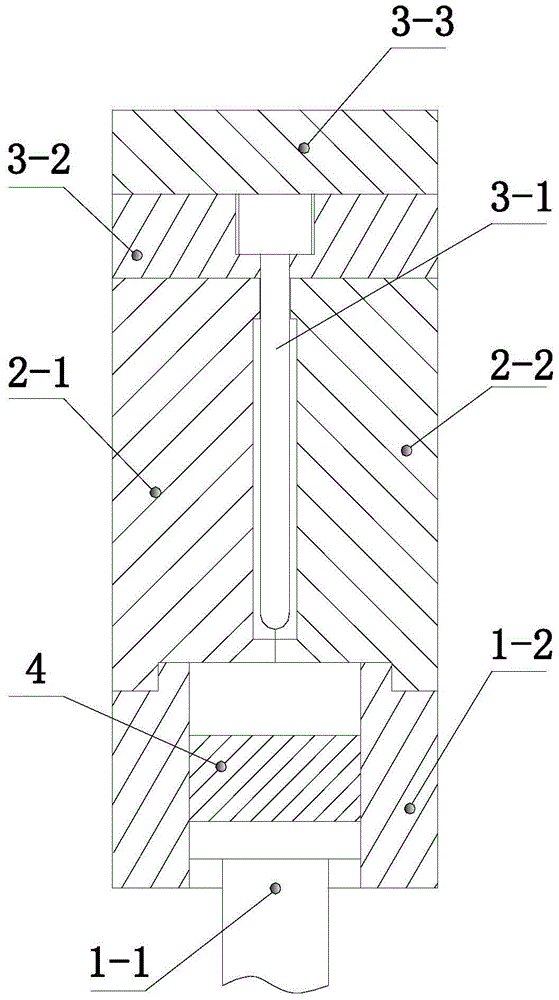

[0026] 2) Bar radial forging: refer to figure 2 , using residual heat to carry out radial forging on the distorted metal bar stock 2 obtained in step 1), specifically four hammerheads 7 symmetrically distributed around the billet using a radial forging machine, and distorted metal bar stock 2 along the radial direction Perform high-frequency reciprocating forging, and at the same time use the manipulator to drive the distorted metal bar 2 to perform axial feed motion while rotating, so that the billet will be elongated and thinned under the co...

Embodiment 2

[0032] Embodiment 2, the specific implementation process of this embodiment is similar to that of Embodiment 1, the difference is that the mold cavity of the waveguide radial forging type strain-induced semi-solid extrusion die is different, and the waveguide in Embodiment 1 moves horizontally to the left The mold cavity formed by the module 2-1, the waveguide horizontal right moving module 2-2 and the descending waveguide inner hole type moving module 3-1 is a cylindrical cavity, while the mold cavity in Example 2 is a rectangular cylinder shape cavity, with reference to the forming process of embodiment 1, the waveguide preliminary forming part 5 and waveguide forming part 6 obtained in embodiment 2 are rectangular, such as Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com