Biochemical treatment method of industrial wastewater and aerobic tank

A technology for industrial wastewater and biochemical treatment, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., and can solve problems such as differences in treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

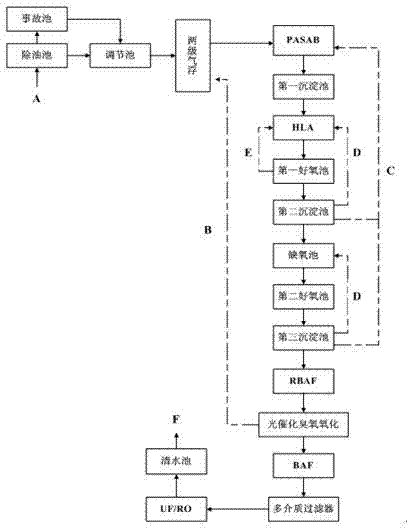

[0017] See attached picture. figure 1 Among them, A is blue charcoal wastewater; B is residual ozone; C is residual sludge; D is sludge return; E is mixed liquid return; F is effluent or reuse.

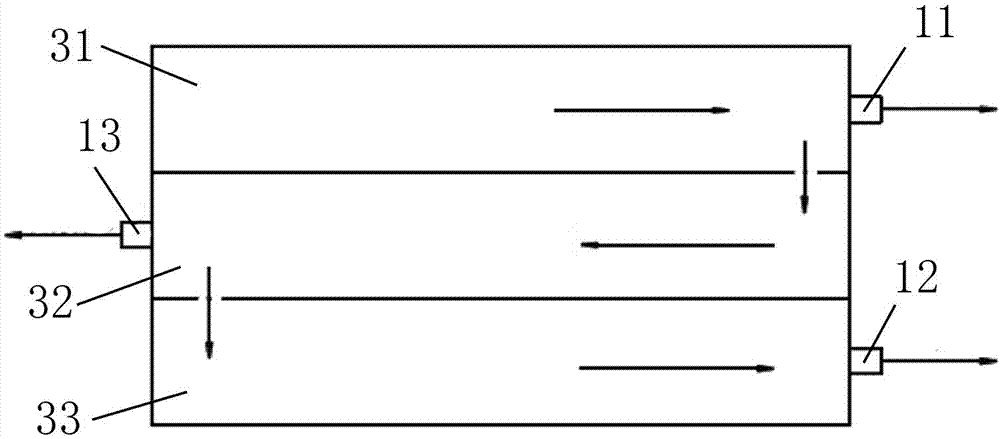

[0018] The blue charcoal wastewater in this project comes from the wastewater of a blue charcoal production plant after ammonia distillation, dephenolization, and deoiling. It is composed of phenolic wastewater and oily wastewater (at a 4:6 inflow). Water quality indicators As shown in Table 1, press figure 1 The design of the process flow is 1m 3 / h device is running. Among them, the first aerobic pool is divided into three sections, 31, 32, and 33, which together form an S-shaped corridor, in which water flows in the direction of the arrow. There are three return ports 11, 13, and 12 on the corridor. As can be seen from the figure, they are respectively located at 1 / 3, 2 / 3 and the end of the process.

[0019]

[0020] The overall processing procedure of this embodiment is as follows.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com