A kind of imitation pine wood decoration material and preparation method thereof

A decorative material, pine wood technology, applied in the field of building materials, can solve the problems of reducing early strength, gelling, high water content, long cement hydration time and long setting time, so as to improve strength and water resistance, reduce soluble substances, Achieving the effect of sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] raw material:

[0040] Phosphogypsum 60kg, fly ash 8kg, yellow phosphorus slag 20kg and quicklime 1kg.

[0041] Preparation:

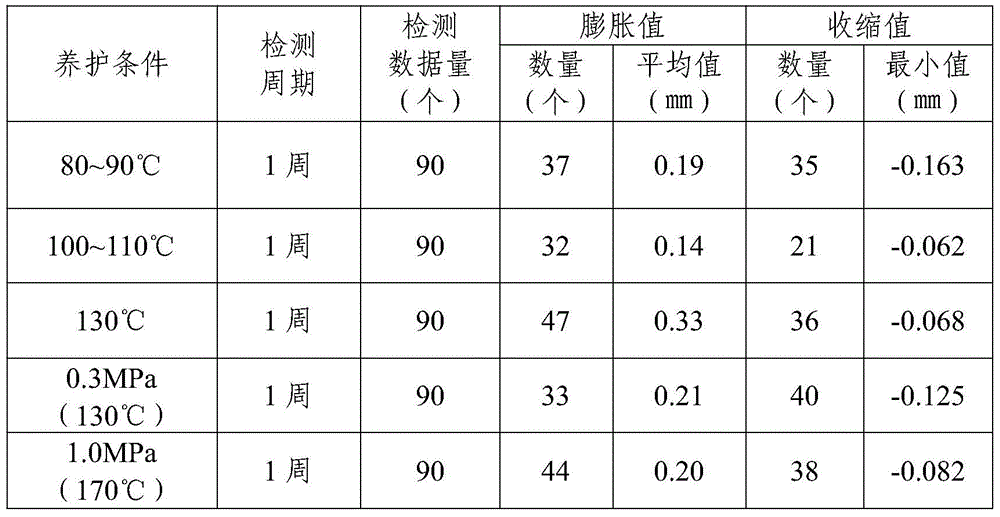

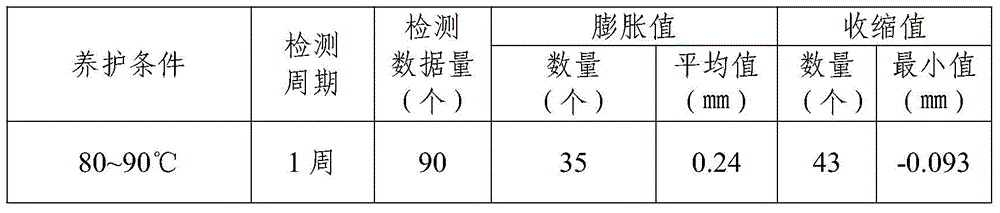

[0042] The yellow phosphorus slag was ball-milled into 80-mesh fine powder at a temperature of 50°C to obtain slag powder, and then the phosphogypsum, fly ash, cement, slag powder and quicklime were stirred and reacted at a temperature of 20°C for 5 hours, and the obtained mixed material was After natural aging treatment for 16 days, add 10% water of the weight of the mixed material to the aged mixed material and stir evenly, pour it into the mold, obtain the formed phosphogypsum base material after demoulding, and mix the phosphogypsum base material Send it to a curing room with normal pressure and a steam temperature of 100°C for 16 hours of curing treatment, slowly dry the cured phosphogypsum base material at a temperature of 70°C until the moisture content is 3%, and then sand it with 240# sandpaper Make it smooth to 0.5mm, then spray nitr...

Embodiment 2

[0045] raw material:

[0046] Phosphogypsum 70kg, fly ash 12kg, yellow phosphorus slag 30kg and quicklime 5kg.

[0047] Preparation:

[0048] The yellow phosphorus slag was ball-milled into 100-mesh fine powder at a temperature of 60°C to obtain slag powder, and then the phosphogypsum, fly ash, cement, slag powder and quicklime were stirred and reacted at a temperature of 30°C for 5 hours, and the obtained mixed material was After natural aging treatment for 24 days, add water with 15% weight of the mixed material to the aged mixed material and stir evenly, pour it into the mold, and obtain the formed phosphogypsum base material after demoulding, and the phosphogypsum base material Send it to a curing room with normal pressure and a steam temperature of 110°C for 18 hours. Slowly dry the cured phosphogypsum base material at a temperature of 80°C until the moisture content is 3%, and then sand it with 240# sandpaper Make it smooth so that the flatness is 2mm, then spray nitro...

Embodiment 3

[0051] raw material:

[0052] Phosphogypsum 62kg, fly ash 9kg, yellow phosphorus slag 22kg and quicklime 2kg.

[0053] Preparation:

[0054] The yellow phosphorus slag was ball milled into 100-mesh fine powder at a temperature of 52°C to obtain slag powder, and then the phosphogypsum, fly ash, cement, slag powder and quicklime were stirred and reacted at a temperature of 23°C for 6 hours, and the obtained mixed material was After natural aging treatment for 18 days, add water with 12% weight of the mixed material to the aged mixed material and stir evenly, pour it into the mold, obtain the formed phosphogypsum base material after demoulding, and mix the phosphogypsum base material Send it to a curing room with normal pressure and a steam temperature of 103°C for 16 hours of curing treatment, slowly dry the cured phosphogypsum base material at a temperature of 72°C until the moisture content is 4%, and then sand it with 240# sandpaper Make it smooth to 1.5mm, then spray nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com