Environmental-protective stone-imitation floor and preparation method thereof

A technology of imitating stone and floor, applied in the field of environment-friendly imitation stone floor and its preparation, can solve the problems of prolonged setting time, long production process, high cementitiousness and high water content, achieve a wide range of raw material sources, enhance comprehensive performance, and improve solidification performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] raw material:

[0040] Phosphogypsum 40kg, coagulant 1kg, fiber 0.1kg, yellow phosphorus slag 15kg and quicklime 4kg.

[0041] Preparation:

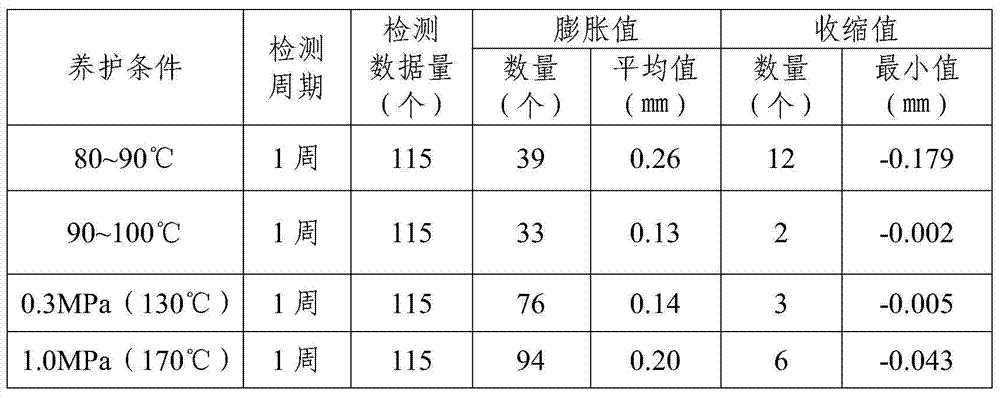

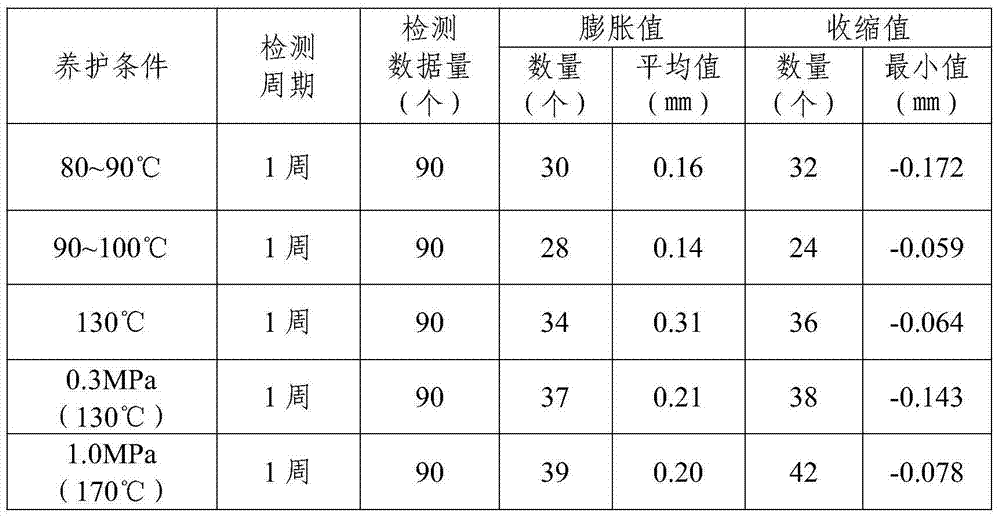

[0042] Put the yellow phosphorus slag and phosphogypsum into the mixer and mix them, stir and react for 2 hours at a temperature of 100°C and a stirring speed of 3000r / min, and then grind them into 80-mesh fine powder to obtain phosphorus slag powder, mix fiber, coagulant and Add quicklime to the phosphorus slag powder, adjust the temperature to 40°C, stir for 2 hours at a stirring speed of 2500r / min, then naturally age for 10 days, add water with a weight of 14% of the mixed material to the obtained mixed material, stir and mix evenly After that, it is poured into the mold, and the formed phosphogypsum base material is obtained after demolding, and the phosphogypsum base material is placed in a steam curing room with normal pressure and a steam temperature of 90°C for 20 hours, and the cured base material After slowly drying at...

Embodiment 2

[0045] raw material:

[0046] Phosphogypsum 60kg, coagulant 3kg, fiber 2kg, yellow phosphorus slag 30kg and quicklime 8kg.

[0047] Preparation:

[0048] Put the yellow phosphorus slag and phosphogypsum into the mixer and mix them, stir and react for 3 hours at a temperature of 120°C and a stirring speed of 3500r / min, and then grind them into 100-mesh fine powder to obtain phosphorus slag powder, mix fiber, coagulant and Add quicklime to the phosphorus slag powder, adjust the temperature to 60°C, stir for 3 hours at a stirring speed of 3000r / min, then naturally age for 10 days, add water with a weight of 18% of the mixed material to the obtained mixed material, stir and mix evenly After that, it is poured into the mold, and the molded phosphogypsum substrate is obtained after demoulding. The phosphogypsum substrate is placed in a steam curing room with normal pressure and a steam temperature of 100°C for 22 hours, and the cured substrate is After slowly drying at 40°C until ...

Embodiment 3

[0051] raw material:

[0052] Phosphogypsum 45kg, coagulant 1.5kg, fiber 0.5kg, yellow phosphorus slag 20kg and quicklime 5kg.

[0053] Preparation:

[0054] Put the yellow phosphorus slag and phosphogypsum into the mixer and mix them, stir and react for 3 hours at a temperature of 105°C and a stirring speed of 3100r / min, then grind them into 100-mesh fine powder to obtain phosphorus slag powder, mix fiber, coagulant and Add quicklime to the phosphorus slag powder, adjust the temperature to 45°C, stir at a stirring speed of 2600r / min for 2 hours, then naturally age for 6 days, add water with 15% of the weight of the mixed material to the obtained mixed material, stir and mix evenly After that, it is poured into the mold, and the molded phosphogypsum substrate is obtained after demoulding. The phosphogypsum substrate is placed in a steam curing room with normal pressure and a steam temperature of 92°C for 21 hours, and the cured substrate is After slowly drying at 32°C until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com