Preparation method of urea-formaldehyde foamed plastics for thermal insulation

A urea-formaldehyde foam plastic, thermal insulation technology, which is applied in the field of urea-formaldehyde foam plastic preparation, can solve the problems of physical health damage of processing personnel, high requirements on production equipment, toxic and harmful fumes, etc., to ensure the overall thermal insulation effect, high production efficiency, The effect of not polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

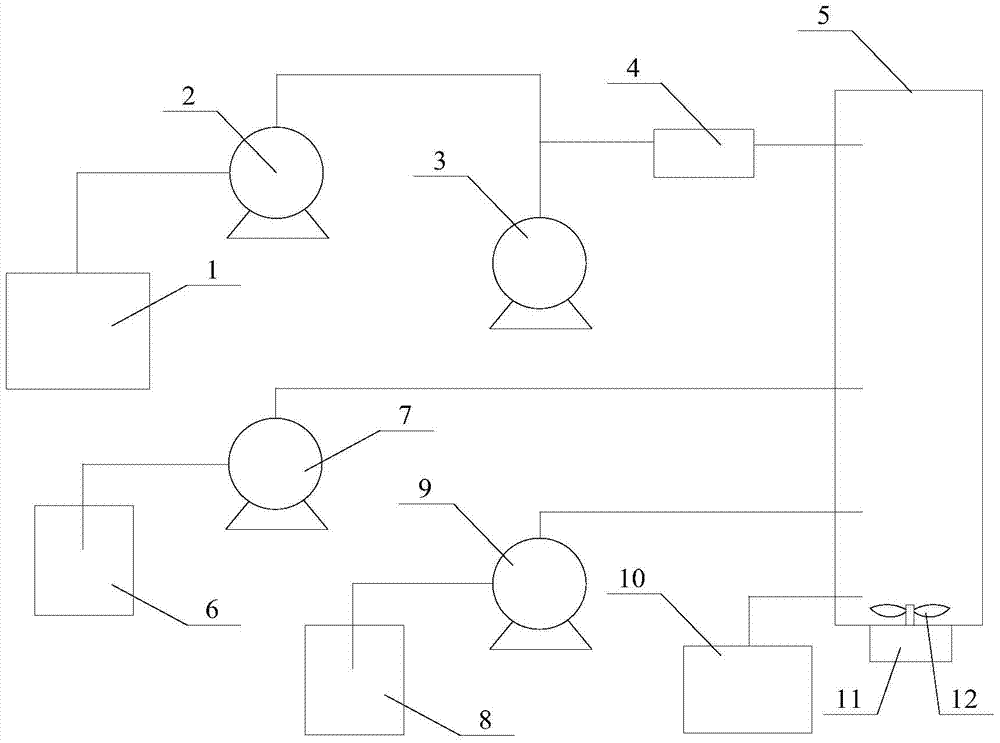

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

[0045] A urea-formaldehyde foam plastic for thermal insulation: it consists of 40-45% urea-formaldehyde resin, 46-50% water, 0.4-0.5% surfactant, 2-3% curing agent and inorganic filler as the balance.

[0046] A urea-formaldehyde foam plastic for thermal insulation: it consists of 41-44% urea-formaldehyde resin, 47-49% water, 0.41-0.49% surfactant, 2.2-2.8% curing agent and inorganic filler as the balance.

[0047] A urea-formaldehyde foamed plastic for thermal insulation: it consists of 43% urea-formaldehyde resin, 48% water, 0.45% surfactant, 2.5% curing agent and the balance is inorganic filler according to mass percenta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com