Oilfield produced water low-boiling pressurized condensation heat exchange equipment and technology

A technology for condensing heat exchange and producing water, which is applied in the field of low-grade heat energy utilization processes and equipment, can solve the problems of blockage of heat exchangers and many components of tertiary oil recovery polymers, and achieves the effect of stable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

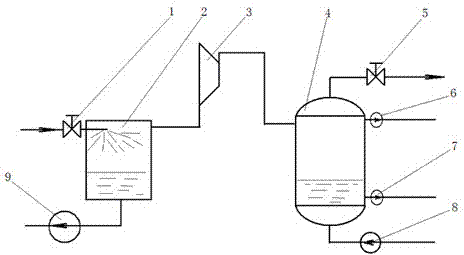

[0016] combined with figure 1 , to further describe the present invention:

[0017] A low-boiling pressurized condensation heat exchange equipment for oilfield produced water mentioned in the present invention comprises oilfield produced water inlet valve 1, low-pressure steam generator 2, steam supercharger 3, steam condensing heat exchanger 4, and water outlet valve 5 , non-condensable gas suction pump 6, condensate water transfer pump 7, heating water pump 8, oil field produced water transfer booster pump 9, one side of the low pressure steam generator 2 is connected to the low pressure steam generator 2 through the oil field produced water inlet valve 1 High-grade hot water inlet, the bottom is connected to the external discharge reinjection pipeline through the booster pump 9 of oilfield produced water, and the other side of the low-pressure steam generator 2 is connected to the steam booster 3 through a pipeline, and the output end of the steam booster 3 Connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com