A distributed combined cooling, heating and power system based on biomass gas

A technology of combined cooling, heating and power and biomass gas, which is applied in the fuel oil system, biological sludge treatment, machine operation mode, etc. can difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

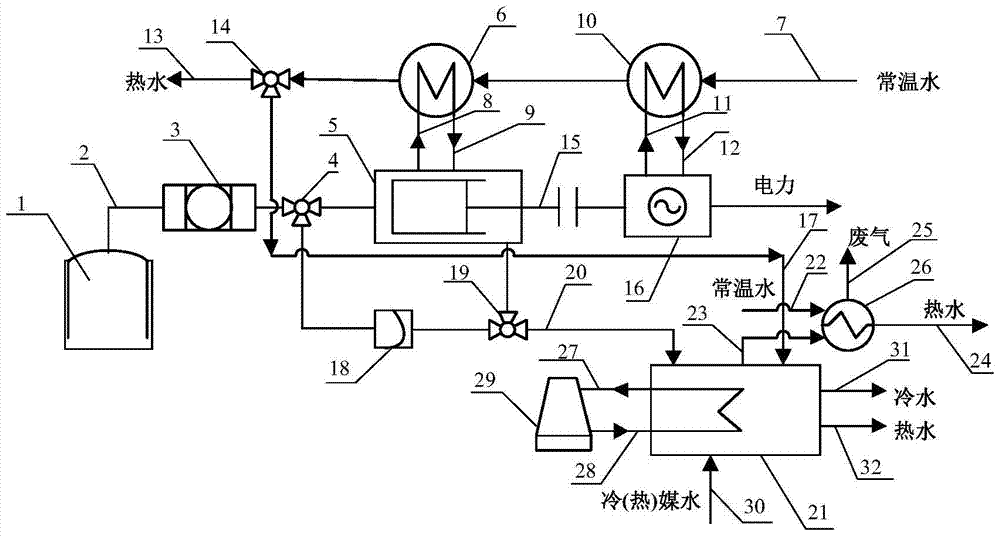

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] Such as figure 1 As shown, the biogas collection device 1 collects and stores the biogas produced by the fermentation of livestock manure in the farm, passes through the smoke pipe 2 into the biogas purification device 3, and then enters the gas internal combustion engine 5 through the first three-way valve 4, and the purified biogas drives the gas internal combustion engine 5 generates power, drives the water-cooled generator 16 to generate electricity through the output shaft 15, and provides electric energy for users.

[0029] The normal temperature water enters the generator heat exchanger 10 through the first water inlet 7 of the normal temperature water, and the generator cooling water enters the generator heat exchanger 10 through the generator cooling water inlet pipe 11 for heat exchange. Enter the jacket water heat exchanger 6, while t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com