Composite thermoelectric material and preparing method thereof

A technology of thermoelectric materials and thermoelectricity, which is applied in the direction of thermoelectric device node lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problems of small phase interface, size, and size difficult to control, and achieve thermal conductivity reduction and thermoelectricity optimization. The effect of increasing the value ZT and suppressing the thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

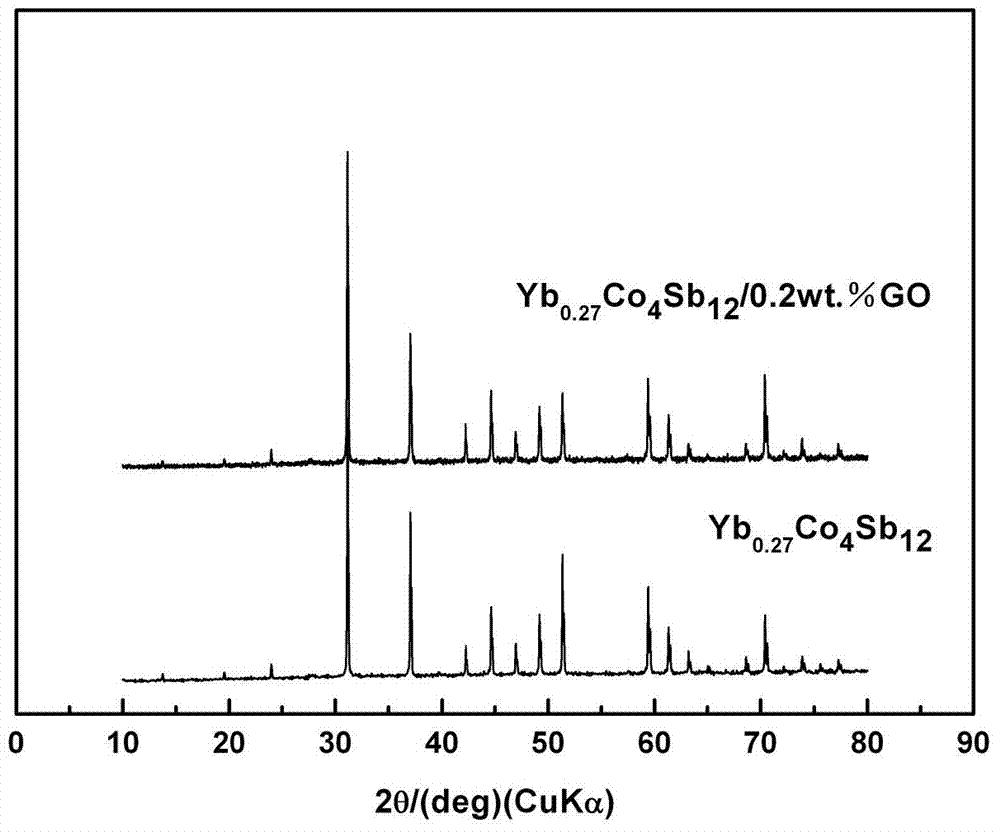

[0031] Example 1Yb 0.27 co 4 Sb 12 Preparation of / 0.2wt%GO

[0032] Yb 0.27 co 4 Sb 12 Preparation of matrix powder: Use pure elements Yb, Co, and Sb as initial raw materials, weigh them in a stoichiometric ratio, and transfer them into a quartz tube. Vacuum packaging is carried out in an argon atmosphere glove box using a plasma flame packaging method at a vacuum degree of 1-10 Pa. Then place it in a vertical melting furnace, raise the temperature to 1080°C at a rate of 5°C / min, keep it melted for 12 hours, and quench in ice water. Then place it in a tubular annealing furnace for annealing, raise the temperature to 790°C at a rate of 5°C / min, and anneal at a constant temperature for 168h. Annealed ingots were ground in a mortar to Yb 0.27 co 4 Sb 12 Base powder.

[0033] Preparation of graphene oxide GO: Weigh 1g of graphite powder into a round-bottomed flask, put it in an ice-water bath on a magnetic stirrer, add 50mL of 98% concentrated sulfuric acid and 3.5g of...

Embodiment 2

[0037] Example 2Yb 0.27 co 4 Sb 12 Preparation of / 0.5wt%GO

[0038] Yb 0.27 co 4 Sb 12 The preparation of matrix powder and GO is the same as in Example 1.

[0039] Preparation of Yb by liquid phase composite method 0.27 co 4 Sb 12 / 0.5wt%GO composite thermoelectric material: 1.5g Yb obtained by rough grinding 0.27 co 4 Sb 12 The matrix powder was mixed with 150mL, 0.05mg / mL GO solution, and ultrasonically treated at 50HZ for 1h, filtered for 2h and dried in a 60 vacuum oven for 12h. The dried powder is finely ground to obtain composite thermoelectric material powder. Finally, the composite thermoelectric material powder was plasma sintered at 600° C. and 60 MPa for 15 minutes to obtain a composite thermoelectric material block.

[0040] Depend on Figure 5 It can be seen that the thermoelectric performance measurement shows that in the measured temperature range (300-850K), compared with Yb 0.27 co 4 Sb 12 As far as the matrix is concerned, the electrical ...

Embodiment 3

[0041] Example 3Ce 0.85 Fe 3 CoSb 12 Preparation of / 0.2wt%GO

[0042] Ce 0.85 Fe 3 CoSb 12 Preparation of matrix powder: Use pure elements Ce, Fe, Co, and Sb as initial raw materials, weigh them according to the stoichiometric ratio, and then transfer them into a quartz tube. Vacuum packaging is carried out in an argon atmosphere glove box using a plasma flame packaging method at a vacuum degree of 1-10 Pa. Then place it in a vertical melting furnace, raise the temperature to 1100°C at a rate of 5°C / min, keep it melted for 12 hours, and quench in ice water. Then place it in a tubular annealing furnace for annealing, raise the temperature to 700°C at a rate of 5°C / min, and anneal at a constant temperature for 168h. Annealed ingots were ground in a mortar to Ce 0.85 Fe 3 CoSb 12 Base powder.

[0043] The preparation of GO is the same as in Example 1.

[0044] Preparation of Ce by liquid phase composite method 0.85 Fe 3 CoSb 12 / 0.2wt%GO composite thermoelectric m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com