Method for manufacturing high-efficiency perovskite type solar cell through large crystal grain forming

A solar cell and perovskite-type technology, applied in circuits, photovoltaic power generation, electrical components, etc., to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

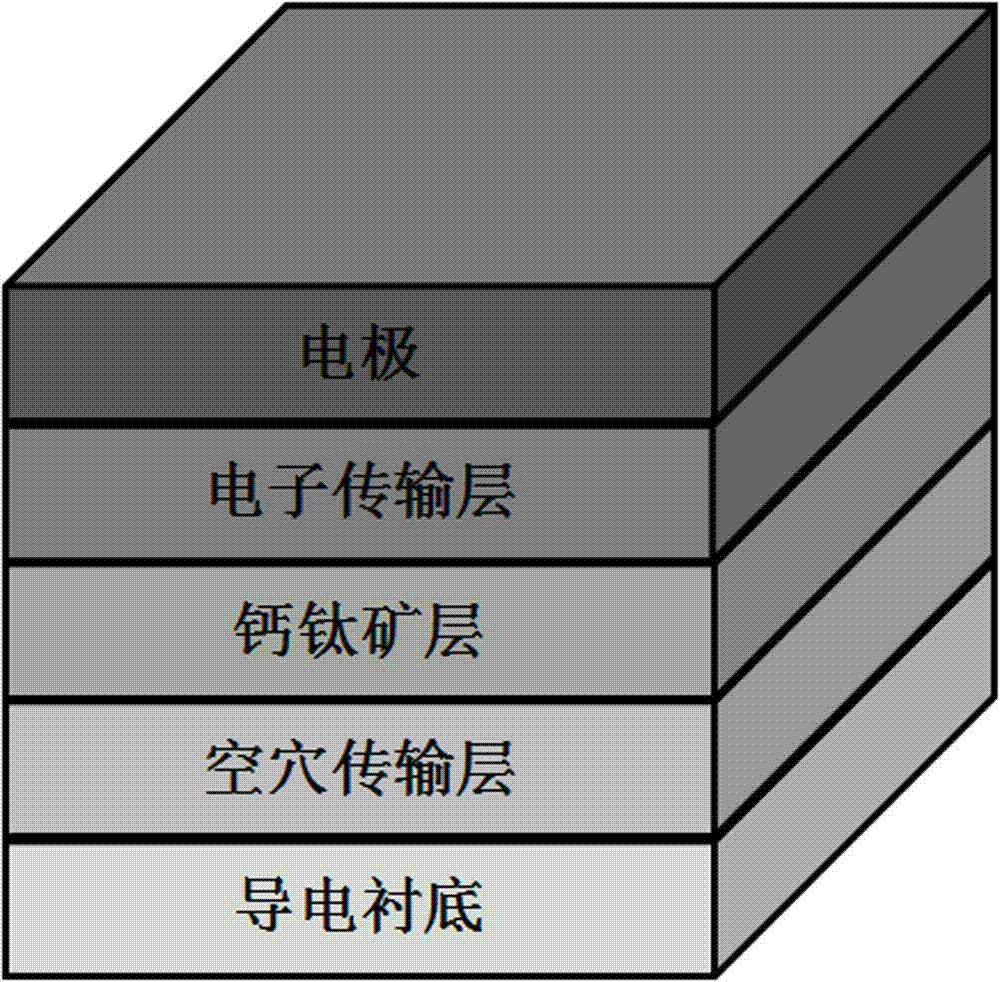

[0038] 1) Reference figure 1 , the perovskite-type solar cell includes a conductive substrate, a hole transport layer, a perovskite layer, an electron transport layer and an electrode from top to bottom.

[0039] 2) After cleaning the ITO glass with detergent, ultrasonically clean it with acetone, absolute ethanol, and deionized water in sequence, take it out, and dry it with nitrogen.

[0040] 3) Spin-coat PEDOT:PSS on a conductive substrate by solution spin-coating, and heat the substrate at 180°C.

[0041] 4) CH with a molar ratio of 1:1 3 NH 3 I and PbI 2 was dissolved in DMF solvent to form a yellow mixed solution, and the temperature was maintained at 70° C., then dropped on the substrate, immediately spin-coated at 4500 rpm for 3 seconds, and then naturally cooled to room temperature.

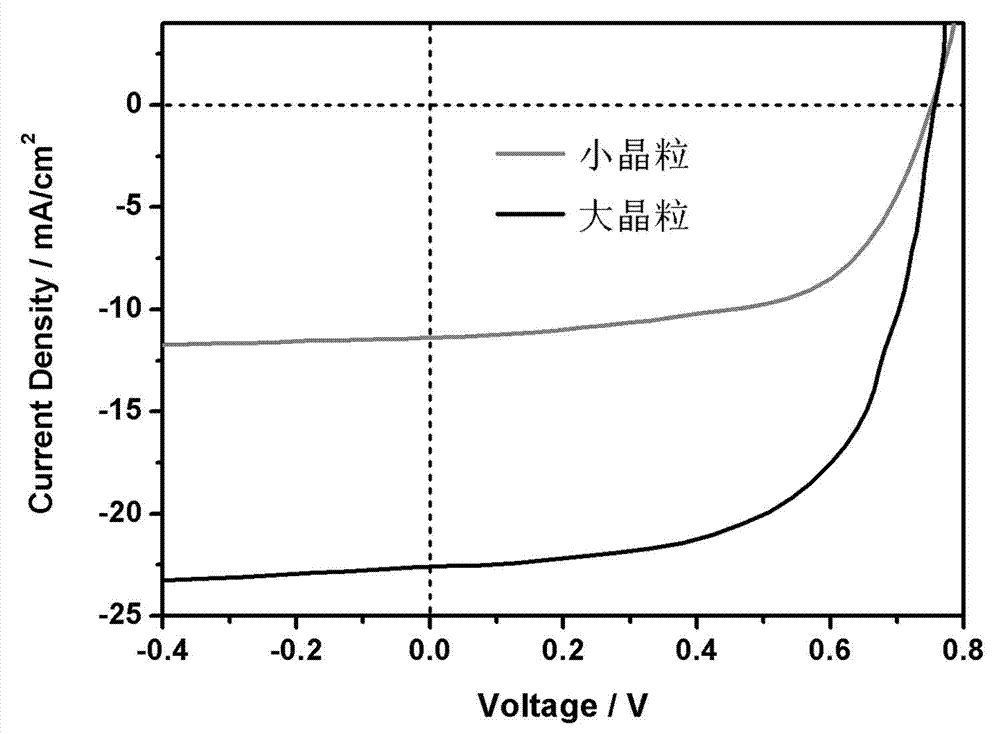

[0042] 5) At the same time as a comparative test, the substrate temperature in step 3) was maintained at 120°C, and then step 4) was performed, and the yellow mixed solution was drop...

Embodiment 2

[0048] 1) Clean the ITO glass with detergent, then ultrasonically clean it with acetone, absolute ethanol, and deionized water in sequence, take it out, and blow it dry with nitrogen.

[0049] 2) Spin-coat TiO on conductive substrates by solution spin-coating 2 Precursor solution, then put it into a muffle furnace and heat it to 150-200°C, then treat it at low temperature for about 30 minutes, and then maintain the substrate at 190°C before proceeding to step 3).

[0050] 3) CH with a molar ratio of 1:1 3 NH 3 Cl and PbI 2 was dissolved in NMP solvent to form a yellow mixed solution, and the temperature was maintained at 70° C., then dropped on the substrate, immediately spin-coated at 4000 rpm for 2 seconds, and then naturally cooled to room temperature.

[0051] 4) Spiro-MeOTAD solution was spin-coated on top of the perovskite layer.

[0052]6) Growth of silver electrodes on top of Spiro-MeOTAD.

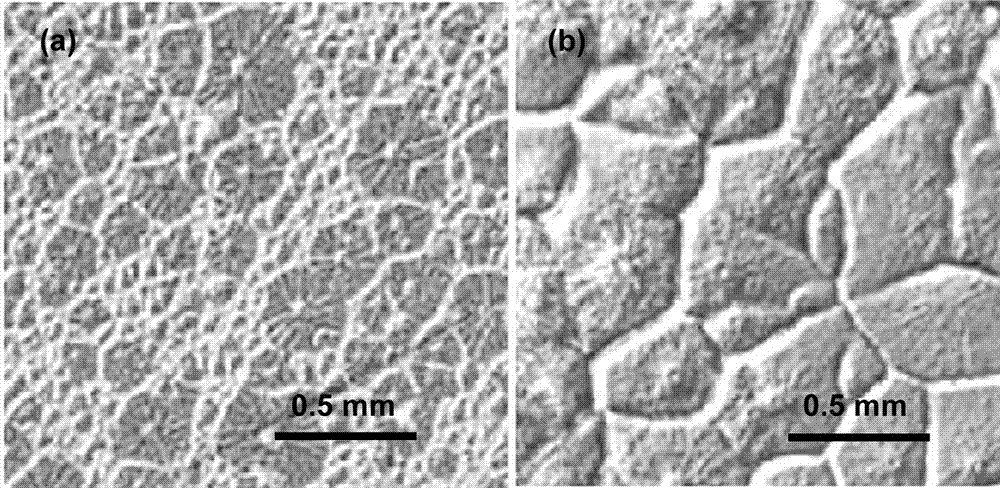

[0053] The optical picture of perovskite layer spin-coating in embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com