Preparation method for motion sensor

A motion sensor and device technology, applied in the manufacture of microstructure devices, techniques for producing decorative surface effects, decorative art, etc., can solve problems such as filling metals are easy to form holes, temperature rises, and device operating voltages increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

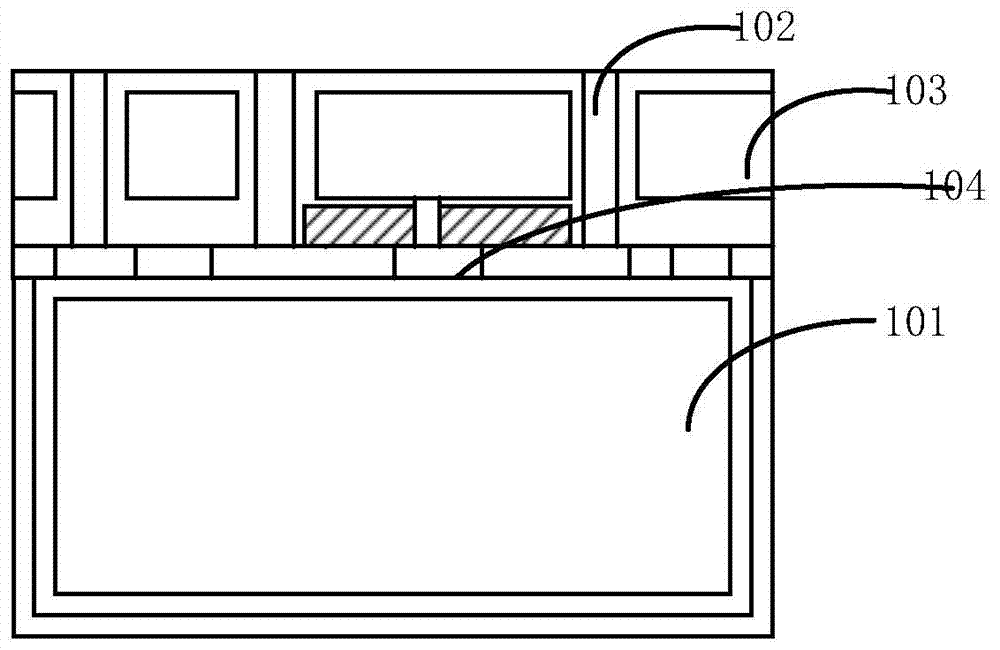

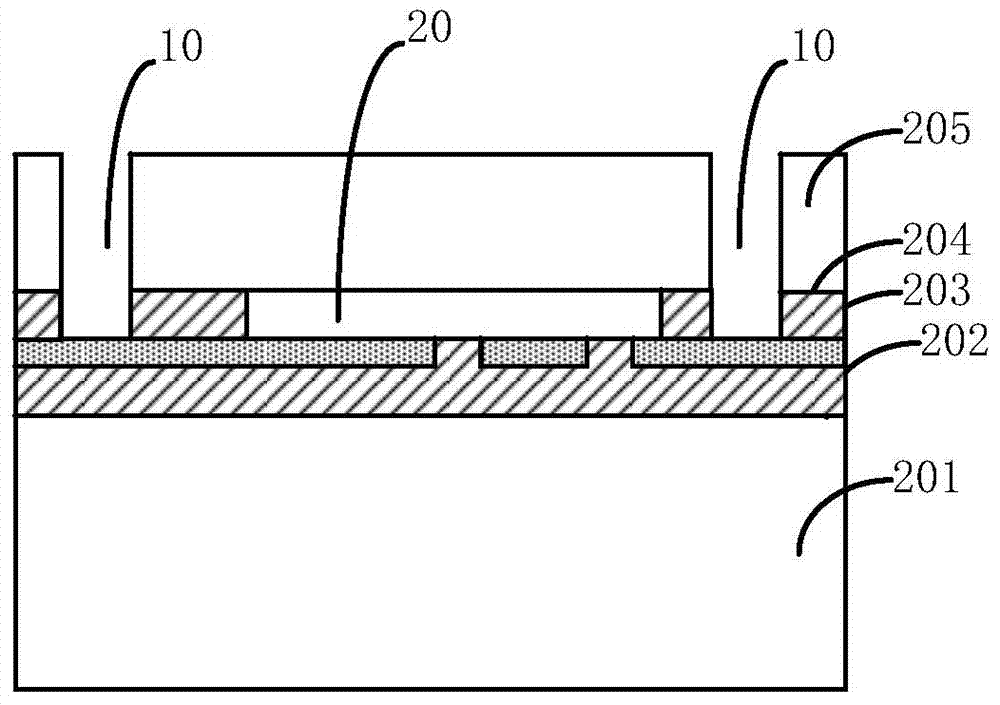

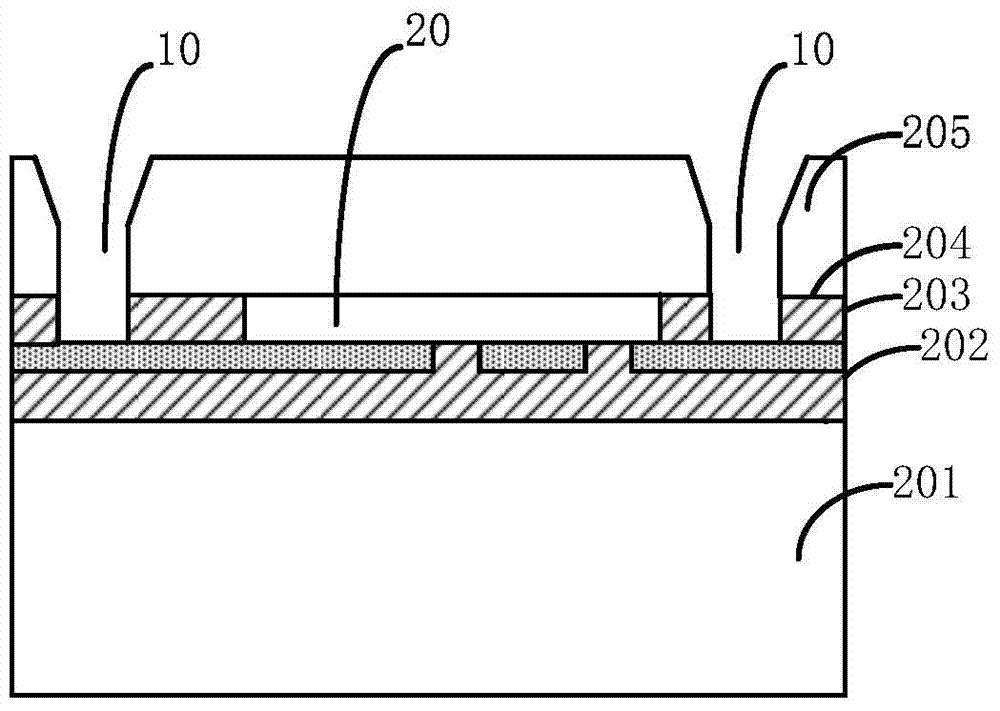

[0059] Attached below Figure 2a-2f A specific embodiment of the present invention will be further described.

[0060] Firstly, step 201 is performed to provide a substrate 201 on which CMOS devices are formed.

[0061] Specifically, refer to Figure 2a , the base 201 includes a semiconductor substrate, and various active devices formed on the substrate, wherein the semiconductor substrate can be at least one of the materials mentioned below: silicon, silicon-on-insulator (SOI), silicon-on-insulator (SSOI), silicon-germanium-on-insulator (S-SiGeOI), silicon-germanium-on-insulator (SiGeOI) and germanium-on-insulator (GeOI), etc.

[0062] Various active devices are formed on the semiconductor substrate, for example, CMOS devices and other active devices are formed on the semiconductor substrate, and the active devices are not limited to a certain type.

[0063] Next, step 202 is performed to form a bottom electrode 203 on the substrate 201 .

[0064] Specifically, the method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com