A kind of imitation granite decorative plate and preparation method thereof

A technology of imitating granite and decorative boards, applied in the field of building materials, can solve the problems of long cement hydration time, prolonged setting time, long production process, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] raw material:

[0040] Phosphogypsum 30kg, cement 1kg, yellow phosphorus slag 15kg and quicklime 0.1kg.

[0041] Preparation:

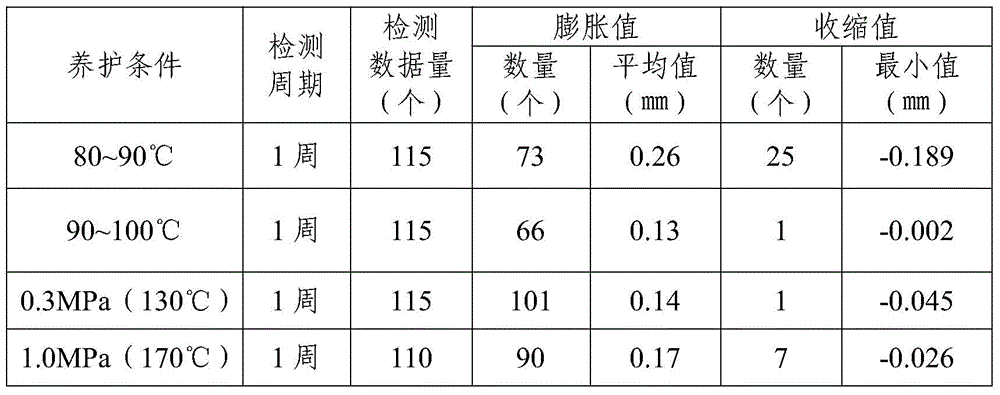

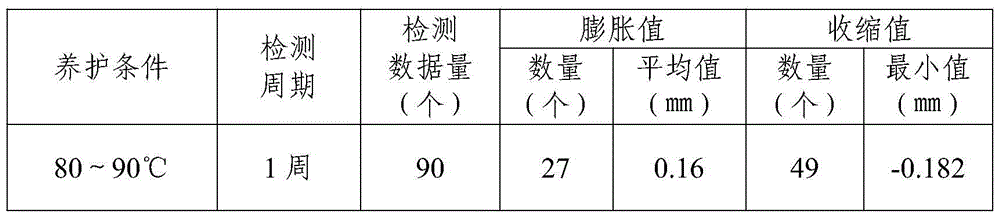

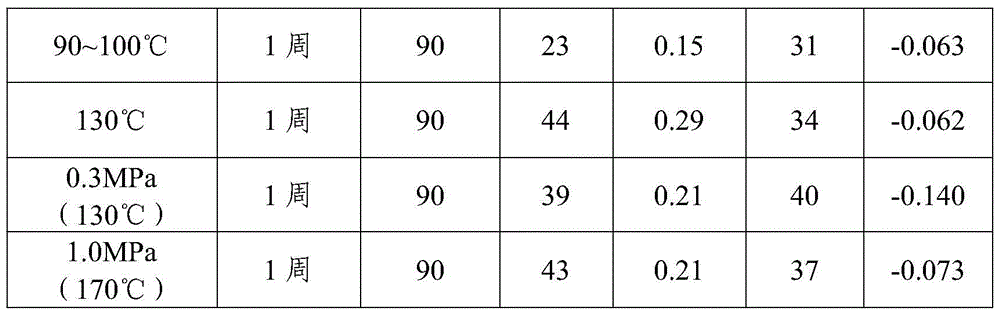

[0042] Mix yellow phosphorus slag, cement, quicklime and phosphogypsum, stir and react for 4 hours in a mixer with a temperature of 80°C and a stirring speed of 3000r / min, and then grind it into an 80-mesh fine powder. Natural aging treatment in the environment of water droplets for 10 days, adding 13% water of the weight of the mixed material to the aged mixed material and mixing evenly, pouring into the mold, placing the formed phosphogypsum base material under normal pressure, Curing treatment in a curing room with a temperature of 90°C and a relative humidity of 85% for 20 days, slowly drying the treated phosphogypsum substrate at a temperature of 30°C until the moisture content is 3-5%, and then drying the surface treatment to make the surface evenness 0.5mm, and then coat polyester oil paint white paint with a thickness of 0.5mm, dry at...

Embodiment 2

[0045] raw material:

[0046] Phosphogypsum 80kg, cement 20kg, yellow phosphorus slag 60kg and quicklime 10kg.

[0047] Preparation:

[0048] Mix yellow phosphorus slag, cement, quicklime and phosphogypsum, stir and react for 6 hours in a mixer with a temperature of 100°C and a stirring speed of 3500r / min, and then grind it into a 100-mesh fine powder. Natural aging treatment in the environment of water droplets for 16 days, adding 15% water of the weight of the mixed material to the aged mixed material and mixing evenly, then pouring into the mold, placing the formed phosphogypsum base material under normal pressure, Curing treatment in a curing room with a temperature of 100°C and a relative humidity of 95% for 20 days, slowly drying the treated phosphogypsum substrate at a temperature of 40°C until the moisture content is 3%, and then treating its surface, Make the surface evenness 2mm, then coat polyester oil varnish white paint with a thickness of 1mm, dry it at a tempe...

Embodiment 3

[0051] raw material:

[0052] Phosphogypsum 60kg, cement 6kg, yellow phosphorus slag 25kg and quicklime 2kg.

[0053] Preparation:

[0054] Mix yellow phosphorus slag, cement, quicklime and phosphogypsum, stir and react for 5 hours in a mixer with a temperature of 85°C and a stirring speed of 3100r / min, and then grind it into an 80-mesh fine powder. Natural aging treatment in the environment of water droplets for 12 days, adding 14% water of the weight of the mixed material to the aged mixed material and mixing evenly, pouring into the mold, placing the formed phosphogypsum base material under normal pressure, Curing treatment for 17 days in a curing room with a temperature of 92°C and a relative humidity of 89%, slowly drying the treated phosphogypsum substrate at a temperature of 32°C until the moisture content is 4%, and then treating its surface, Make the surface evenness 0.8mm, then coat polyester oil paint white paint with a thickness of 0.9mm, dry it at 42°C for 16 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com