Hydrolysis device for continuously synthesizing glyphosate and application of hydrolysis device

A hydrolysis device and glyphosate technology, applied in the fields of compounds of group 5/15 elements of the periodic table, organic chemistry, chemical instruments and methods, etc., to achieve the effects of reduced energy consumption, large heat exchange area, and stable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

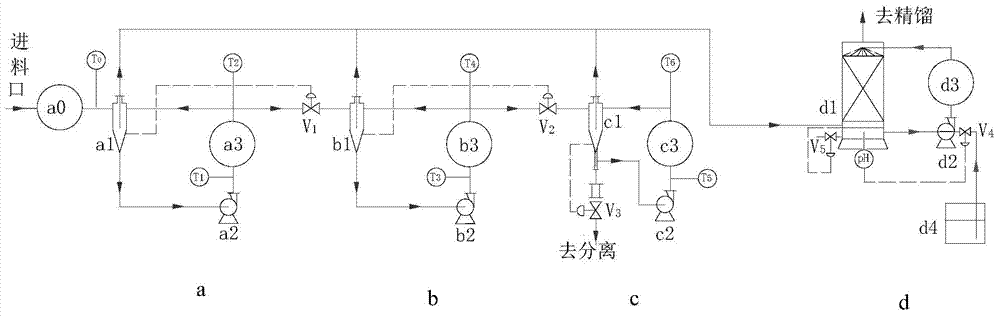

Embodiment 1

[0038] Pump the condensate (mainly containing compound 1, but also triethylamine, methanol, unreacted raw materials and by-product methylal, etc.) and 30% hydrochloric acid at a flow rate of 4kg / min and 2.1kg / min respectively of the mixture. The mixed liquid is heated by the heating equipment a0, the reaction temperature is controlled at T2=70°C, and then enters the gas-liquid separator a1, the gas phase part flows out from the upper part, and the liquid phase flows out from the lower part and is transported by the circulating pump a2 (the flow rate of the circulating pump is controlled to be about 100L / min), the heating equipment a3 returns to a1 to form a circular reaction system a, the reaction temperature of the circular reaction system a is controlled at 70°C, part of the reaction liquid flows out from the branch, and is linked with the liquid level of the gas-liquid separator a1 The regulating valve V1 enters the gas-liquid separator b1. The gas phase part flows out fro...

Embodiment 2

[0040] Pump the mixture of condensate and 30% hydrochloric acid at flow rates of 4kg / min and 2.1kg / min respectively. The mixed liquid is heated by the heating equipment a0, and the reaction temperature T2=68°C is controlled, and then enters the gas-liquid separator a1, the gas phase part flows out from the upper part, and the liquid phase flows out from the lower part and is transported by the circulation pump a2 (flow rate is about 100L / min), heated The equipment a3 returns to a1 to form a circular reaction system a. The reaction temperature T2 of the circular reaction system a is controlled at T2=70°C. Part of the reaction liquid flows out from the branch port and enters the gas-liquid through the regulating valve V1 linked with the liquid level of the gas-liquid separator a1. Separator b1, the gas phase part flows out from the upper part, the liquid phase flows out from the lower part and is transported by the circulating pump b2 (flow rate is about 80L / min), the heating equ...

Embodiment 3

[0042] Pump the mixture of condensate (containing compound 1) and 30% hydrochloric acid at flow rates of 4kg / min and 2.1kg / min respectively. The mixed liquid is heated by the heating equipment a0, the reaction temperature is controlled at T2=40°C, and then enters the gas-liquid separator a1, the gas phase part flows out from the upper part, and the liquid phase flows out from the lower part and is transported by the circulating pump a2 (flow rate is about 100L / min), The heating equipment a3 returns to a1 to form a cyclic reaction system a. The reaction temperature of the cyclic reaction system a is controlled at 40°C. Part of the reaction liquid flows out from the branch port and enters the gas through the regulating valve V1 linked with the liquid level of the gas-liquid separator a1. In the liquid separator b1, the gas phase part flows out from the upper part, and the liquid phase flows out from the lower part through the circulating pump b2 (flow rate is about 80L / min), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com