Full-body graining polyethylene plastic wood composite and preparation method thereof

A technology of imitating wood grain and polyethylene, applied in the field of whole-body imitating wood grain polyethylene wood-plastic profiles and its preparation, can solve the problem of poor wood grain effect of plastic wood profiles, poor user experience, and restrictions on the recycling of waste high-density polyethylene plastics To achieve the effect of effective recycling, avoiding trouble, and flexible color control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

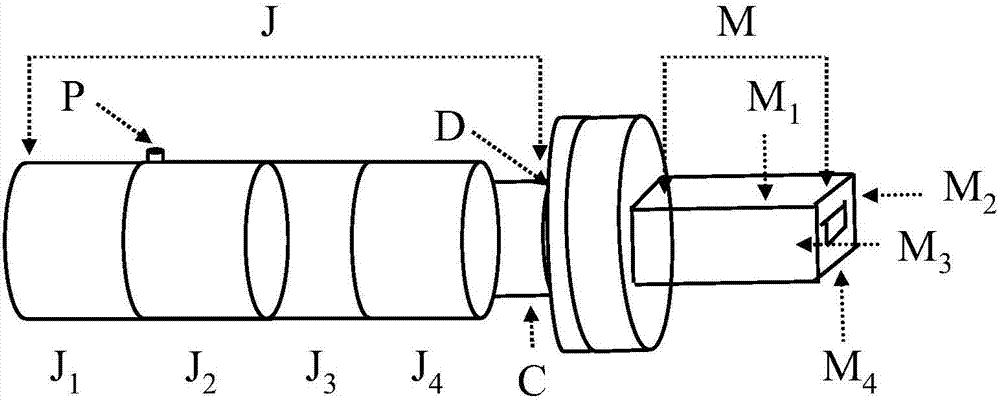

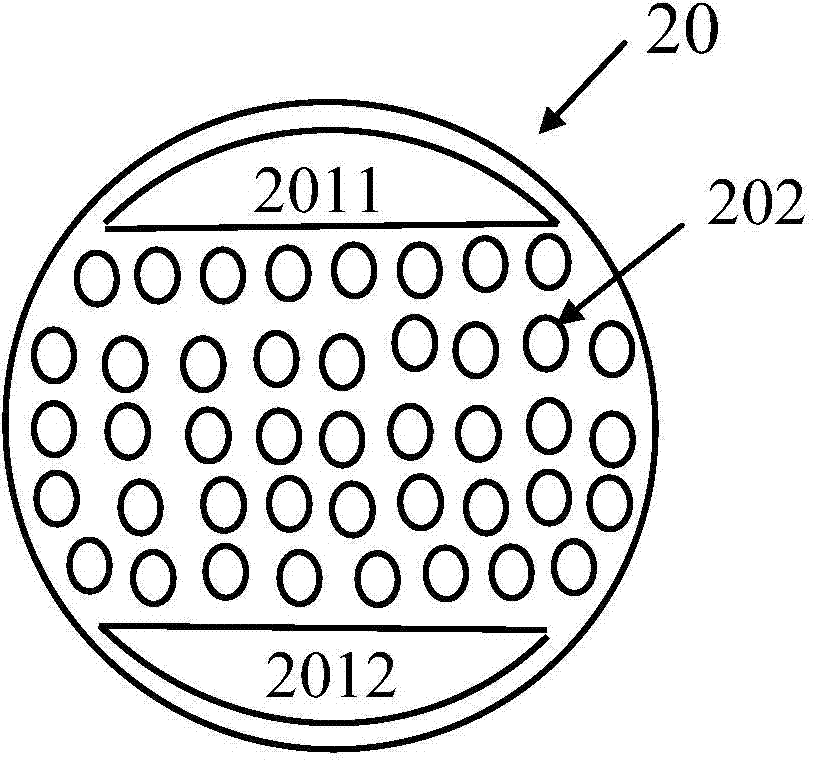

Method used

Image

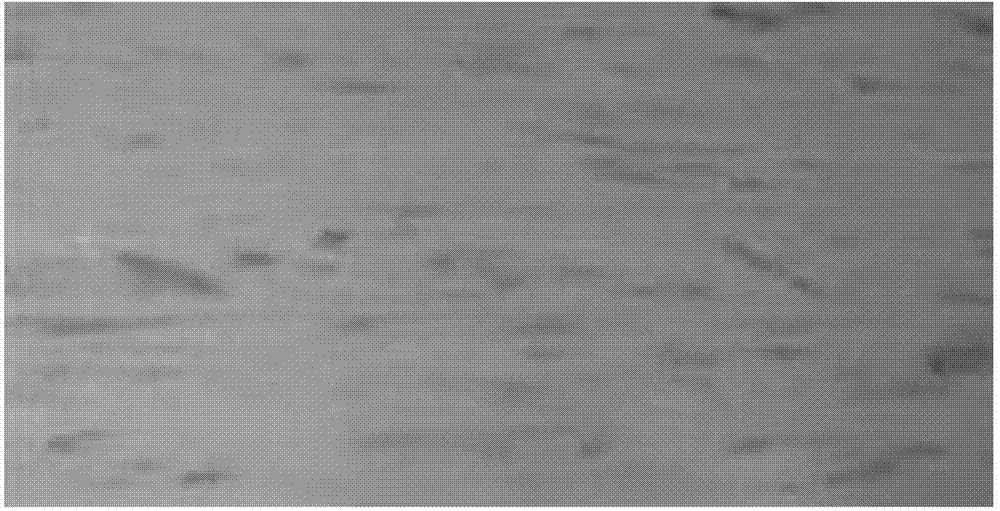

Examples

Embodiment 1

[0071] A whole-body imitation wood-grain polyethylene wood-plastic profile, including a mixed material formed by a color masterbatch and a base material, and the mass percentages of the color masterbatch and the base material in the mixed material are respectively 10% and 90%; specifically of,

[0072] In parts by weight, the color masterbatch includes the following components: calcium carbonate 22, polyethylene wax 18, low-density polyethylene 868-00018, first high-density polyethylene recycled material 30, iron red 11.9, carbon black 0.1;

[0073] The base material includes the following components: second high-density polyethylene recycled material 28, wood powder 55.9, inorganic filler 8, composite lubricant 2.0, antioxidant 10100.1, auxiliary antioxidant 1680.1, ultraviolet absorber UV-5310.2, horse To acid anhydride grafting 1.2, iron yellow 2.5, antifungal agent 2.

Embodiment 2

[0075] A whole-body imitation wood-grain polyethylene wood-plastic profile, including a mixed material formed by a color masterbatch and a base material, and the mass percentages of the color masterbatch and the base material in the mixed material are 15% and 85% respectively; specifically of,

[0076] In parts by weight, the color masterbatch includes the following components: calcium carbonate 32, polyethylene wax 10, low-density polyethylene 868-00010, first high-density polyethylene recycled material 35.85, iron red 12, carbon black 0.15;

[0077] The base material includes the following components: second high-density polyethylene recycled material 35, wood powder 39.3, inorganic filler 12, composite lubricant 2.5, antioxidant 10100.2, auxiliary antioxidant 1680.2, ultraviolet absorber UV-5310.3, horse To acid anhydride grafting 1.5, iron red 4.0, antifungal agent 5.

Embodiment 3

[0079] A whole-body imitation wood-grain polyethylene wood-plastic profile, including a mixed material formed by a color masterbatch and a base material, and the mass percentages of the color masterbatch and the base material in the mixed material are 20% and 80% respectively; specifically of,

[0080] In parts by weight, the color masterbatch includes the following components: calcium carbonate 25, polyethylene wax 12, low-density polyethylene 868-00018, first high-density polyethylene recycled material 34, iron yellow 10.88, carbon black 0.12;

[0081] The base material includes the following components: second high-density polyethylene recycled material 30, rice bran powder 50.45, inorganic filler 10, composite lubricant 2.2, antioxidant 10100.15, auxiliary antioxidant 1680.15, ultraviolet absorber UV-5310.25, horse To acid anhydride grafting 1.3, iron red 3, antifungal agent 2.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com