ITO film and preparation method thereof as well as LED chip and preparation method thereof

A technology of LED chips and thin films, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of increased process time, low process efficiency, poor process quality, etc., to improve process quality, improve process efficiency, and reduce driving voltage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

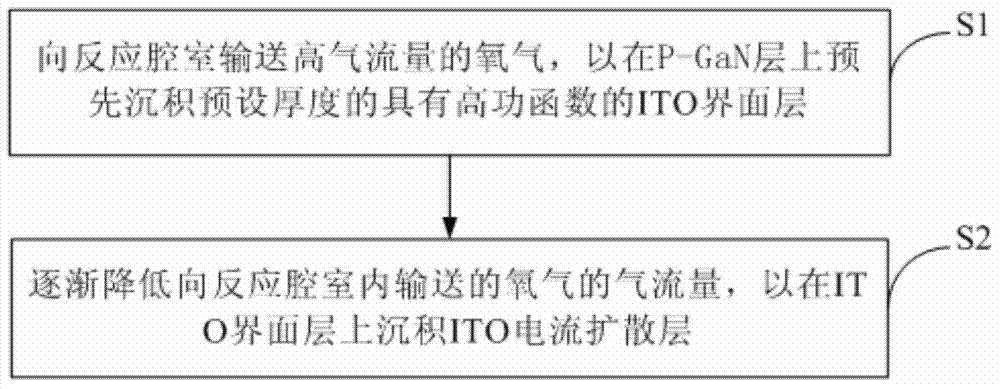

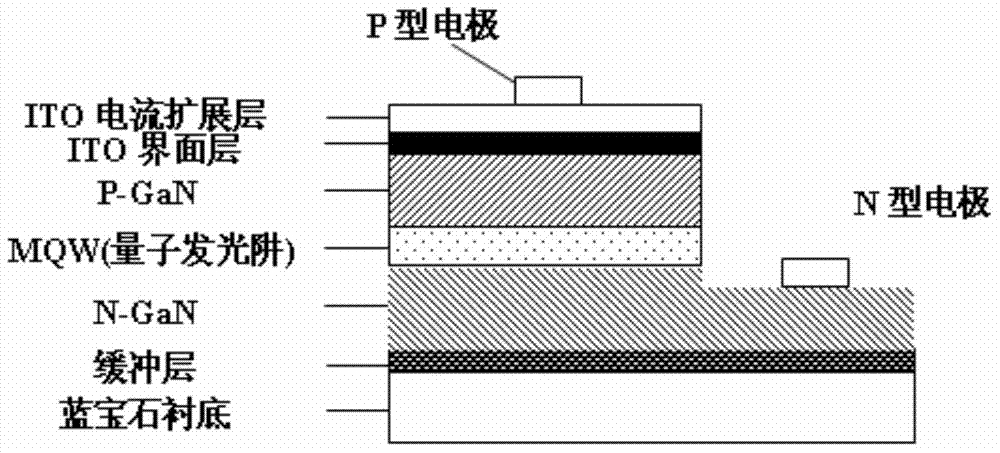

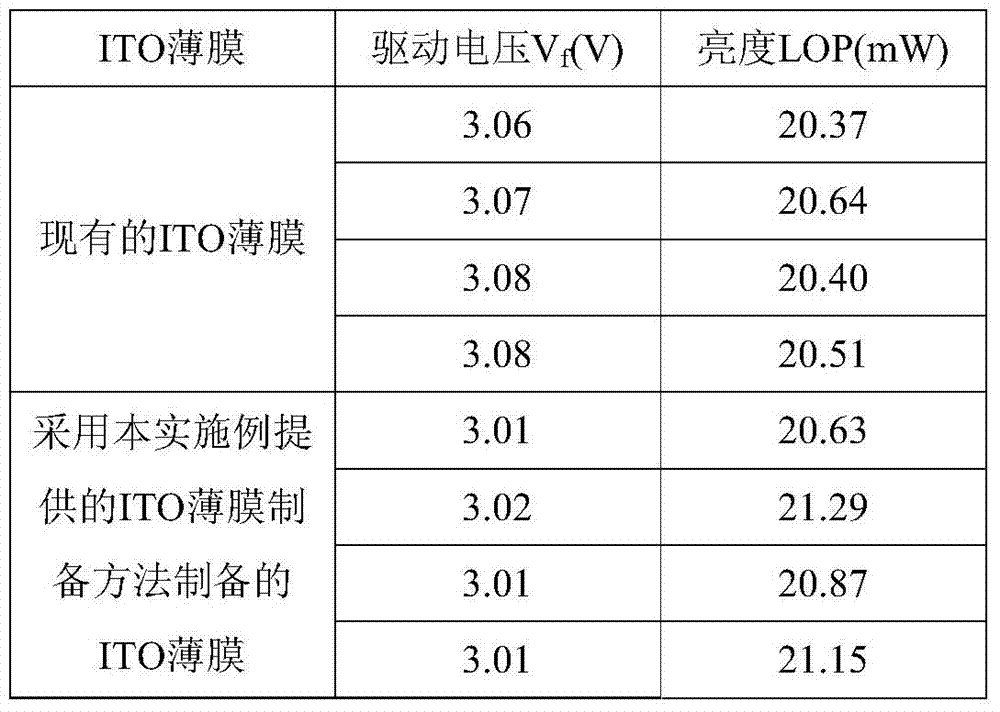

[0031] figure 1 The flow chart of the preparation method of the ITO thin film provided by the embodiment of the present invention. figure 2 It is a schematic structural diagram of an LED chip with an ITO thin film prepared by the preparation method of the ITO thin film provided in this embodiment. Please also refer to figure 1 with figure 2, ITO thin film comprises ITO interface layer and ITO current diffusion layer, the preparation method of the ITO thin film that the present embodiment provides at least comprises the following steps:

[0032] Step S1, delivering high gas flow oxygen into the reaction chamber to pre-deposit an ITO interface layer with a high work function of a preset thickness on the P-GaN layer;

[0033] Step S2, gradually reducing the flow rate of the oxygen gas supplied to the reaction chamber, so as to deposit an ITO current diffusion layer with a graded structure on the ITO interface layer.

[0034] In this embodiment, the ITO interface layer is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com