Polymerizable water-soluble benzophenone type photoinitiator and preparation method thereof

A technology of benzophenones and photoinitiators, which is applied in the field of benzophenone photoinitiators and its preparation, can solve problems such as complex preparation methods, achieve good water solubility, improve water solubility, and high initiation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

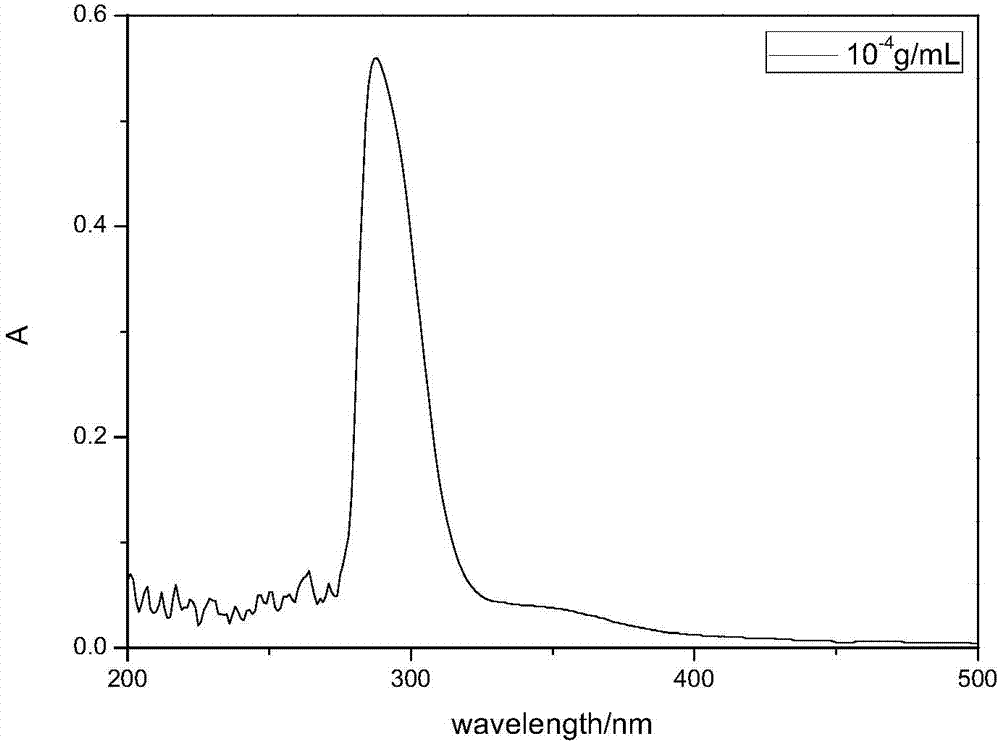

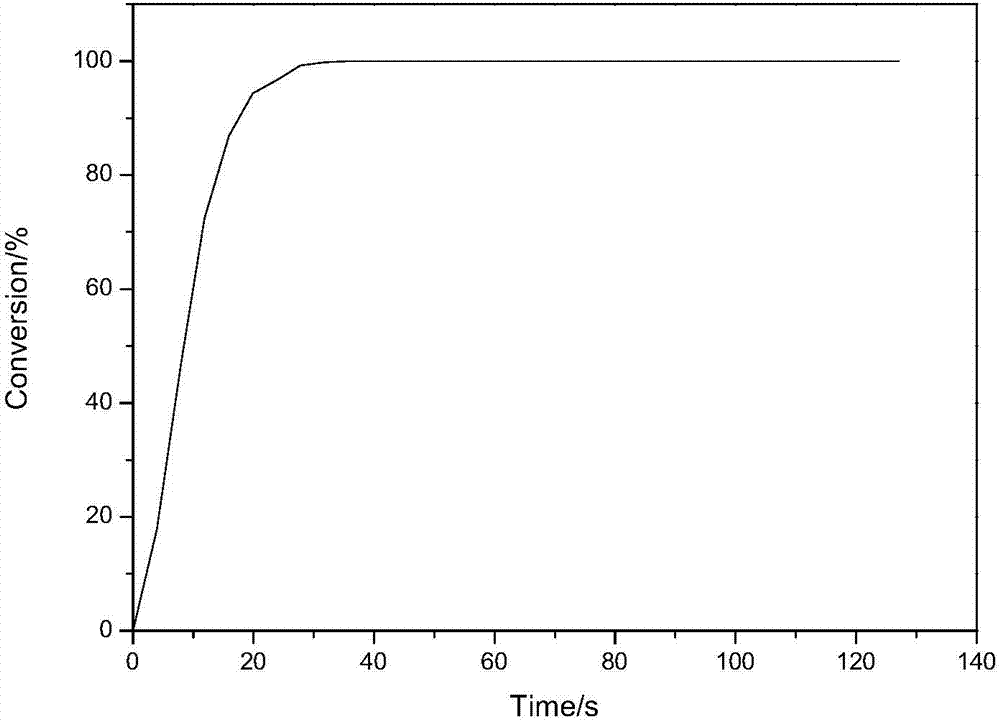

[0028] (1) Weigh 0.05mol (16.1g) of 3,3',4,4'-benzophenone tetra-acid dianhydride and dissolve it in 50mL of dried ethyl acetate, add it to the Put 0.1mol (11.6g) of hydroxyethyl acrylate and 0.1385g of triphenylphosphine directly into the reaction solution in a three-necked flask with a tube and electronic stirring device, stir, heat the oil bath to 80°C, react for 5 hours and then cool to room temperature. The organic solvent was removed by rotary evaporation, washed and extracted with deionized water three times, and dried.

[0029] (2) In order to further improve water solubility, the product was dissolved in 100ml, 1mol / L sodium hydroxide solution, mixed uniformly, and dried again to obtain a polymerizable water-soluble benzophenone photoinitiator.

Embodiment 2

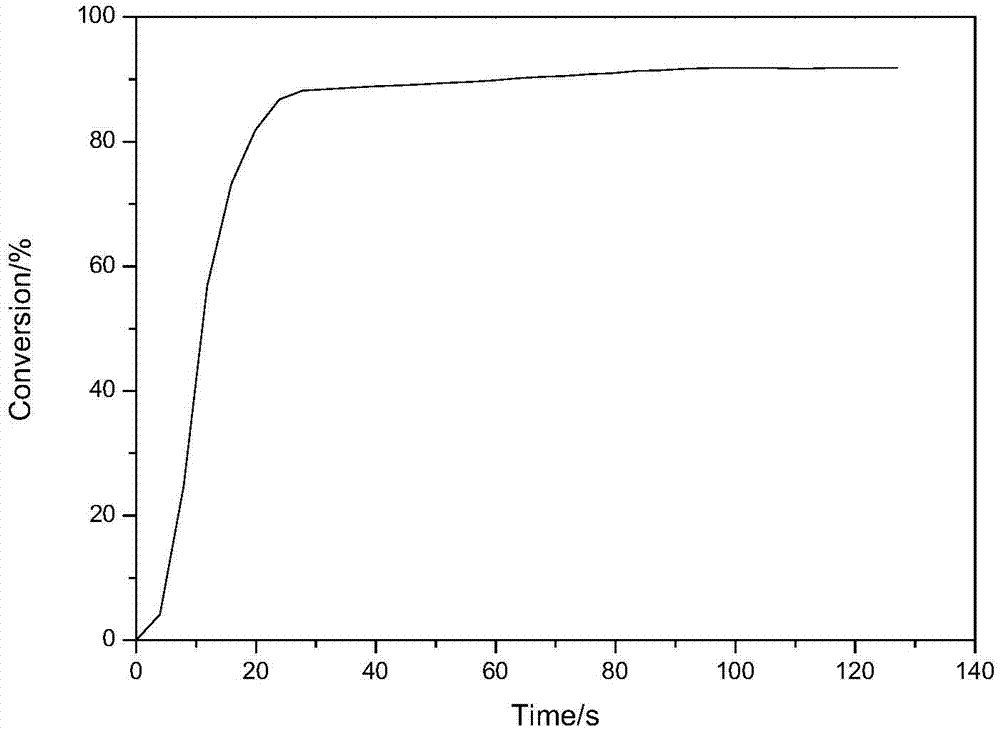

[0031] (1) Weigh 0.05mol (16.1g) of 3,3',4,4'-benzophenone tetra-acid dianhydride and dissolve it in 50mL of dried ethyl acetate, add it to the Add 0.1mol (13.0g) of hydroxyethyl methacrylate and 0.1455g of triphenylphosphine directly into the reaction solution in a three-necked flask with a tube and an electronic stirring device, stir, heat the oil bath to 80°C, and react for 10h After cooling to room temperature. The organic solvent was removed by rotary evaporation, washed and extracted with deionized water three times, and dried.

[0032] (2) In order to further improve water solubility, the product was dissolved in 100ml, 1mol / L potassium hydroxide solution, mixed uniformly, and dried to obtain a polymerizable water-soluble benzophenone photoinitiator.

Embodiment 3

[0034](1) Weigh 0.05mol (16.1g) of 3,3',4,4'-benzophenone tetra-acid dianhydride and dissolve it in 50mL of dried chloroform, and add it to the Add 0.01mol (13.0g) of hydroxypropyl acrylate and 0.0873g of triphenylphosphine directly into the reaction solution in a three-necked flask with a tube and an electronic stirring device, stir, heat the oil bath to 90°C, react for 15 hours and then cool to room temperature. The organic solvent was removed by rotary evaporation, washed and extracted with deionized water three times, and dried.

[0035] (2) In order to further improve water solubility, the product was dissolved in 100ml, 1mol / L diethylamine solution, mixed uniformly, and dried to obtain a polymerizable water-soluble benzophenone photoinitiator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com