Preparation method of antibacterial fiber capable of maintaining cold for long time, and products of antibacterial fiber

An antibacterial fiber and ice-cooling technology, which is applied in the field of preparation of long-lasting ice-cold antibacterial fiber, can solve problems such as fiber performance impact, achieve low volatility, broaden the scope of use, and produce stable and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

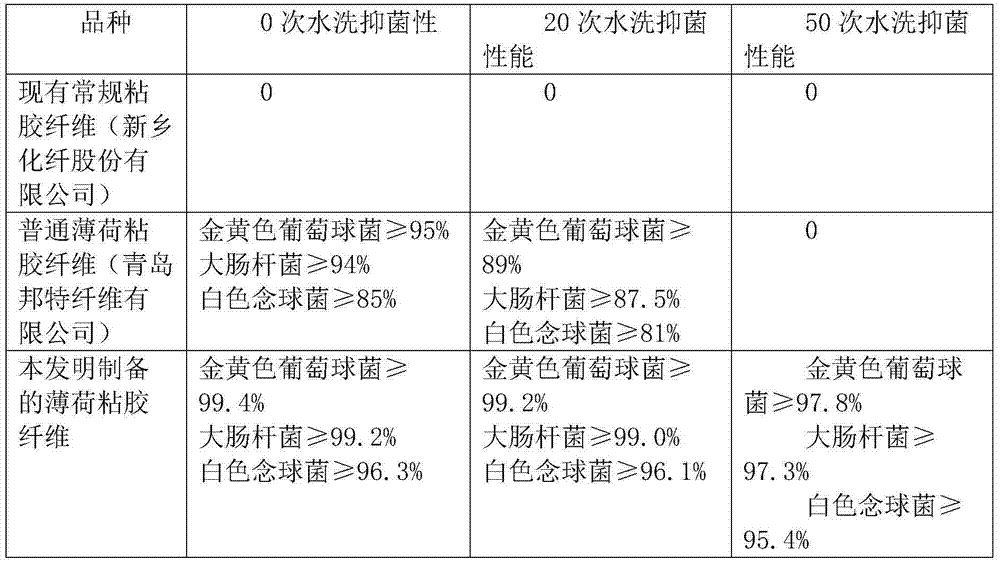

Examples

Embodiment 1

[0030] The preparation method 1 of embodiment 1 antibacterial fiber

[0031] Process steps:

[0032] (1) Pulping: material preparation→cooking→bleaching→washing;

[0033] (2) Spinning: viscose pulp → soaking, pressing, dispersing alkali cellulose aging → yellowing → mixing of peppermint oil microcapsule solution → filtering → defoaming → spinning forming.

[0034] The preparation method of peppermint oil microcapsules is as follows: Weigh 30 g of ethyl cellulose, place it in a stoppered Erlenmeyer flask, add 5 g of ethyl acetate, heat slightly, stir magnetically to dissolve, and cool to room temperature.

[0035] Add peppermint oil 5g in above-mentioned solution then and continue stirring and dissolving to make it become organic phase.

[0036] Dissolve 2 g of sodium lauryl sulfate in distilled water saturated with ethyl acetate to prepare an emulsion containing 1% emulsifier.

[0037] Slowly add the organic phase into the emulsion, control the stirring speed to 100r / min, s...

Embodiment 2

[0046] The preparation method 2 of embodiment 2 antibacterial fibers

[0047] Process steps:

[0048] (1) Pulping: material preparation→cooking→bleaching→washing;

[0049] (2) Spinning: viscose pulp → soaking, pressing, dispersing alkali cellulose aging → yellowing → mixing of peppermint oil microcapsule solution → filtering → defoaming → spinning forming.

[0050] The preparation method of the peppermint oil microcapsule solution is the same as above, and is prepared by an emulsification-solvent diffusion method.

[0051] In the present invention, the stirring time used for emulsion diffusion is 25 minutes.

[0052] In the present invention, the stirring temperature used for emulsion diffusion is 35°C.

[0053] In the present invention, the content of peppermint oil in the peppermint oil microcapsules is 15%.

[0054] In the present invention, the drying time of the peppermint oil microcapsules is 35 minutes.

[0055] In the present invention, in the spinning preparation...

Embodiment 3

[0057] The preparation method 3 of embodiment 3 antibacterial fibers

[0058] Process steps:

[0059] (1) Pulping: material preparation→cooking→bleaching→washing;

[0060] (2) Spinning: viscose pulp → soaking, pressing, dispersing alkali cellulose aging → yellowing → mixing of peppermint oil microcapsule solution → filtering → defoaming → spinning forming.

[0061] The preparation method of the peppermint oil microcapsule solution is the same as above, and is prepared by an emulsification-solvent diffusion method.

[0062] In the present invention, the stirring time used for the dispersion of the emulsion is 30 minutes.

[0063] In the present invention, the stirring temperature used for emulsion diffusion is 40°C.

[0064] In the present invention, the content of peppermint oil in the peppermint oil microcapsules is 20%.

[0065] In the present invention, the drying time of the peppermint oil microcapsules is 45 minutes.

[0066] In the present invention, in the spinning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com