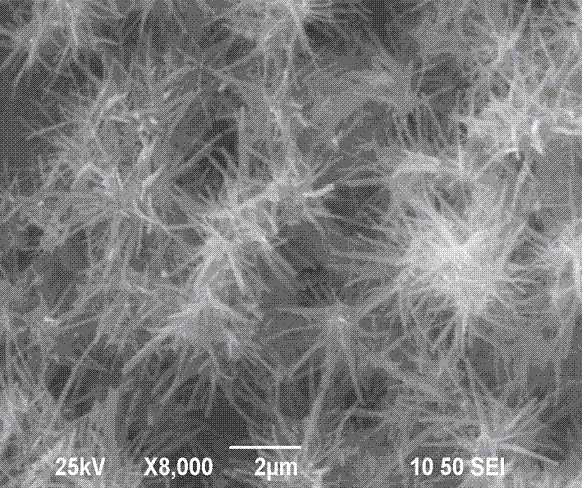

Method for preparing pine-needle-shaped zinc oxide gas sensor

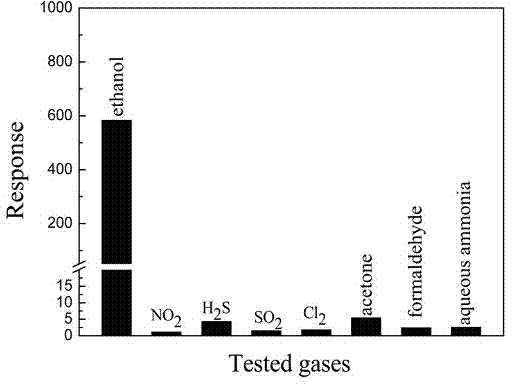

A gas-sensing sensor, zinc oxide technology, applied in the field of gas-sensing sensors, can solve problems such as no related reports, and achieve the effects of good gas-sensing performance, high sensitivity and fast stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Sodium hydroxide solution with a molar concentration of 1mol / L is used to impregnate the cotton fiber for 10 hours and then dried at 90°C for later use. The treated cotton fiber is impregnated in a molar ratio of n (zinc nitrate): n (citric acid) = 4:1 to form 8 hours in the sol, and then dried at 60 ° C to form a gel, and finally the gel was heated to 400 ° C in a temperature-programmed furnace with a heating rate of 1 ° C / min and calcined for 2 hours to obtain pine needle-shaped zinc oxide;

[0012] Weigh 10 mg of the above-prepared pine needle-shaped zinc oxide and put it into an agate mortar, then add anhydrous ethanol and deionized mixed solution with a volume ratio of 1:1, grind for 20 minutes, and then evenly coat it in hydrochloric acid and ethanol for ultrasonic treatment On the alumina ceramic tube core, let it stand to dry for 10h;

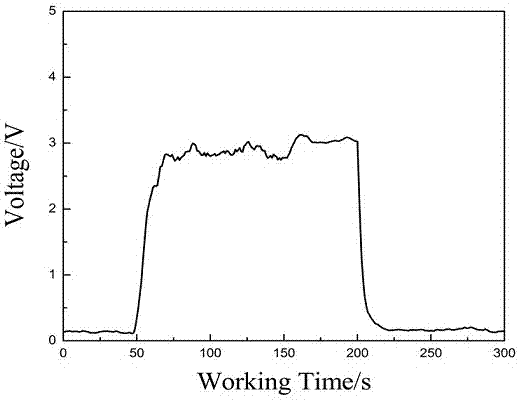

[0013] The coated ceramic tube core was heated to 500°C for 3 hours at a temperature-programmed furnace at a rate of 3°C / min,...

Embodiment 2

[0016] Sodium hydroxide solution with a molar concentration of 3mol / L was used to impregnate the cotton fibers for 8 hours and then dried at 80°C for later use. The treated cotton fibers were impregnated in a molar ratio of n (zinc nitrate): n (citric acid) = 5:1 to form in the sol for 6 hours, then dried at 70°C to form a gel, and finally the gel was heated to 500°C in a temperature-programmed furnace at a rate of 3°C / min and calcined for 2 hours to obtain pine needle-shaped zinc oxide;

[0017] Weigh 1 mg of the above-prepared pine needle-shaped zinc oxide and put it into an agate mortar, then add anhydrous ethanol and deionized mixed solution with a volume ratio of 3:1, grind for 10 minutes, and then evenly coat it in hydrochloric acid and ethanol for ultrasonic treatment On the alumina ceramic tube core, let it stand to dry for 6h;

[0018] The coated ceramic tube core was heated to 450°C for 1 hour at a temperature-programmed furnace at a rate of 1°C / min, and then a resis...

Embodiment 3

[0020] Sodium hydroxide solution with a molar concentration of 6mol / L was used to impregnate the cotton fibers for 4 hours and then dried at 100°C for later use. The treated cotton fibers were impregnated in a molar ratio of n (zinc nitrate): n (citric acid) = 3:1 to form 4h in the sol, and then dried at 80°C to form a gel, and finally the gel was heated to 600°C in a temperature-programmed furnace with a heating rate of 5°C / min and calcined for 2h to obtain pine needle-shaped zinc oxide;

[0021] Weigh 20 mg of the above-prepared pine needle-shaped zinc oxide and put it into an agate mortar, then add anhydrous ethanol and deionized mixed solution with a volume ratio of 2:1, grind for 30 minutes, and then evenly coat it in hydrochloric acid and ethanol for ultrasonic treatment On the alumina ceramic tube core, let it stand to dry for 15 hours;

[0022] The coated ceramic tube core was heated to 550°C for 5 hours at a rate of 5°C / min in a temperature-programmed furnace, and a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com