Perovskite quantum dot material with gas-sensitive property and application thereof

A quantum dot material and perovskite technology, applied in the direction of luminescent materials, analytical materials, material resistance, etc., can solve the problems of unstable performance, poor gas selectivity, etc., and achieve the effect of reducing the density of defect states, increasing the response, and improving the sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

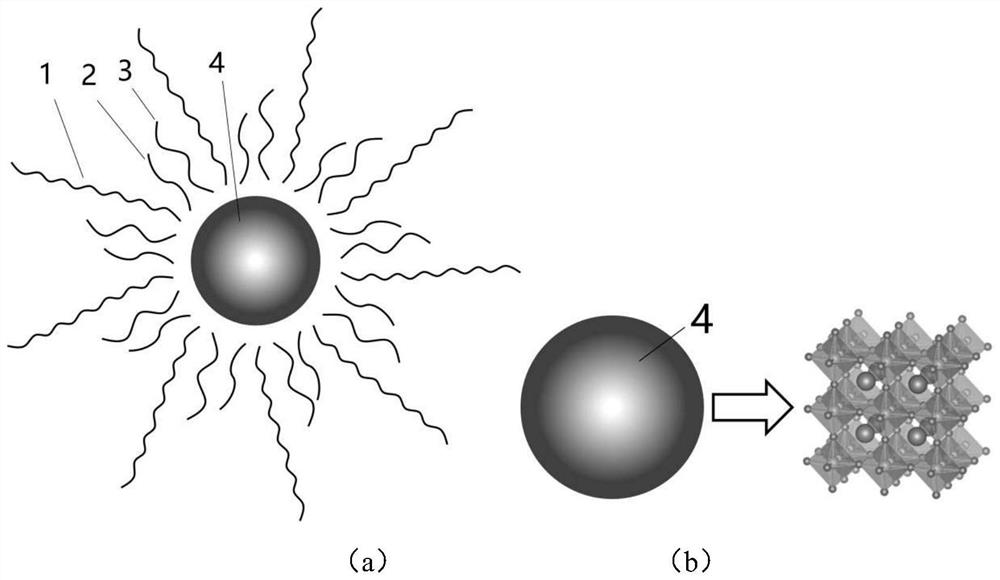

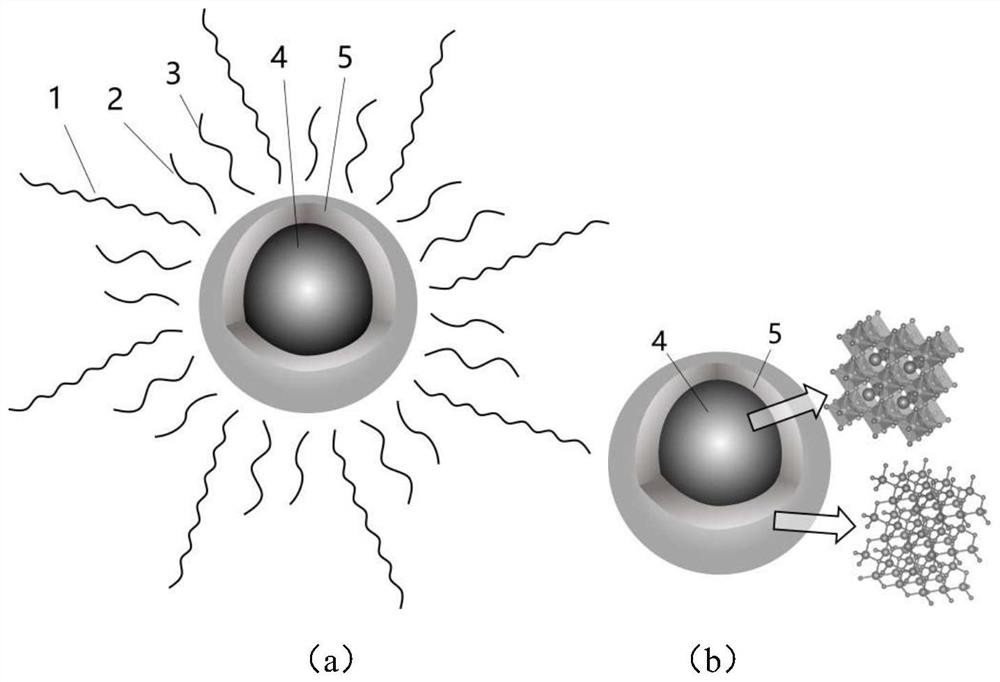

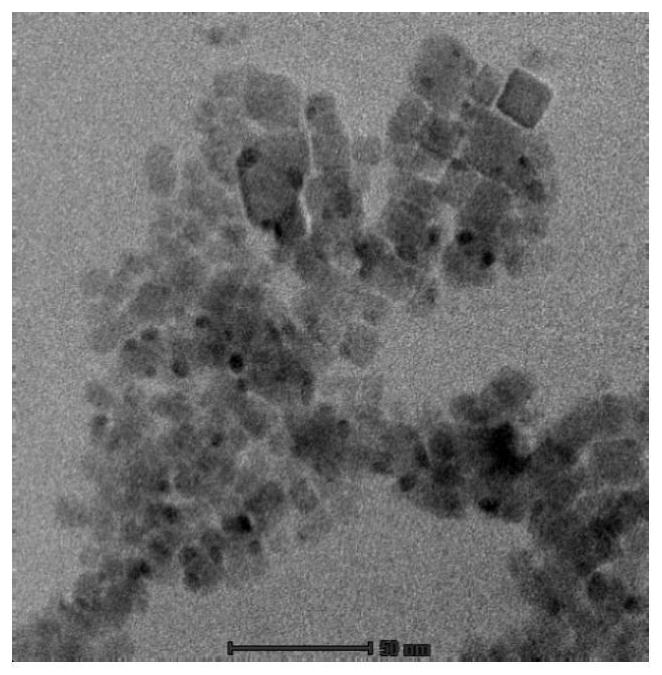

[0034]A gas-sensitive perovskite quantum dot material, the perovskite quantum dot material having gas-sensitive properties consists of a quantum dot core and a surface ligand, the quantum dot core is a metal halide perovskite quantum dot 4 or a metal oxide cladding layer 5 coated metal halide perovskite quantum dots, the surface ligand is an organic acid 1, at least one of the organic amine 3 and a metal-organic ligand 2; the molecular end of the surface ligand is connected by a weak coordination bond and the quantum dot core, The ligand molecules are freely divergent from the quantum dot core outwards; the preparation method of the perovskite quantum dot material with gas-sensitive properties is: 0.05 g cesium carbonate is dissolved in a 0.1mL oleic acid solution on the balance, and the stirring heating table is fully stirred until fully dissolved to obtain a cesium precursor. On the balance, 0.03g of lead bromide and 0.1g of octylamine were weighed, and dissolved in 8mL of tolue...

Embodiment 2

[0042] Preparation method of perovskite quantum dot material with gas-sensitive properties, the steps are:

[0043]Step 1: Preparation of material: 0.5g cesium carbonate is weighed on the balance dissolved in 0.8mL oleic acid solution, and well stirred on the stirring heating table until fully dissolved to obtain the cesium precursor. 0.7 g of lead bromide and 0.9 g of octylamine were weighed on the balance, and dissolved in 10 mL of toluene, and then 0.5 mL of oleic acid and 0.6 mL octylamine were added sequentially, and the lead precursor was obtained by stirring thoroughly on the heating table until dissolved. Take 2mL of lead precursor and 1mL of cesium precursor mixed, stirred on a heating table for 2 hours to obtain cesium lead bromoperovskite quantum dot solution. The solution is yellow in color and glows green under the illumination of ultraviolet light. In the magnetic stirring process, 0.01 mmol of iron acetylacetonate, 0.1 mL of oleic acid and 0.1 mL of octylamine were ...

Embodiment 3

[0049] Preparation method of perovskite quantum dot material with gas-sensitive properties, the steps are:

[0050]Step 1: Preparation of material: Weigh 0.7g of methyl carbonate on the balance dissolved in 2mL oleic acid solution, stir well on the stirring heating table until fully dissolved to obtain a methylamine precursor. 0.8g lead bromide and 0.6g octylamine were weighed on the balance, and dissolved in 6mL of toluene, and then 8mL of oleic acid and 0.6mL octylamine were added sequentially, and thoroughly stirred on the heating table until dissolved to give lead precursors. Take 0.9mL of lead precursor and 0.6mL of cesium precursor mixed, stirred on the heating table for 2 hours to obtain methylamine lead bromoperite quantum dot solution. The solution is yellow in color and glows green under the illumination of ultraviolet light. In the process of magnetic stirring, 0.01mmol of titanium acetylacetonate, 0.1mL of oleic acid and 0.1mL of octylamine were added to the quantum do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com