Method for improving inorganic/organic composite membrane performance through interface modification

An inorganic composite membrane, modified technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effect of wide application, low cost, and improved bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Mix octyltriethoxysilane and toluene at a mass ratio of 1:8 to prepare a silane modification solution.

[0020] (2) The tubular ZrO with an average pore diameter of 200nm 2 / Al 2 O 3 Place it in the modification solution and treat it at 60°C for 2h. Remove the support from the modification solution, put it in an oven, and treat it at 110°C for 4h.

[0021] (3) Take 4 g of polydimethylsiloxane and 60 g of n-hexane, stir evenly and stand still to obtain the PDMS coating liquid.

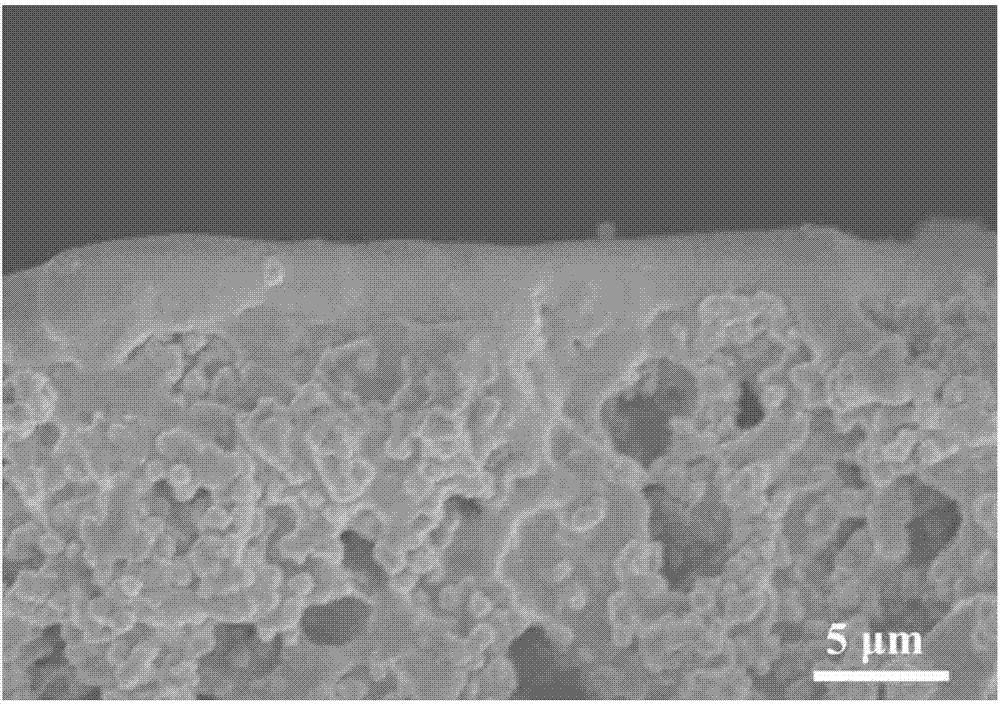

[0022] (4) When the viscosity of the coating liquid is 100mPa·s, apply the coating liquid on the outside of the tubular ceramic support by dipping and pulling. The coating time is 40s. After coating, the film is processed in an oven. It is 80℃, and the time is 1 day. The electron microscope picture of the cross section of the composite membrane is as follows figure 1 Shown.

Embodiment 2

[0028] (1) Mix dodecyltriethoxysilane and xylene at a mass ratio of 1:30 to prepare a silane modification solution.

[0029] (2) The flake TiO with an average pore diameter of 50nm 2 Place it in the modification solution and treat it at 70°C for 2h. Remove the support from the modification solution, put it in an oven, and treat it at 120°C for 3h.

[0030] (3) Take 5g of polyoctyltrimethylsiloxane (POMS) and 70g of n-octane, stir evenly and stand still to obtain the POMS coating liquid.

[0031] (4) When the viscosity of the coating liquid is 50mPa·s, use the dipping and pulling method to 2 The outside of the support is coated with a coating liquid, and the coating time is 60s. After coating, the film is processed in an oven at 100°C for 2 days.

Embodiment 3

[0037] (1) Mix hexadecyltrimethoxysiloxane and absolute ethanol at a mass ratio of 1:40 to prepare a silane modification liquid.

[0038] (2) The hollow fiber Al with an average pore diameter of 300nm 2 O 3 Place it in the modification solution and treat it at 60°C for 4 hours. Remove the support from the modification solution, put it in an oven, and treat it at 100°C for 4 hours.

[0039] (3) Take 3 g of chitosan (CS) and 50 g of n-heptane, stir evenly and stand still to obtain the CS coating liquid.

[0040] (4) When the viscosity of the coating liquid is 20mPa·s, the hollow fiber Al 2 O 3 The outer side of the support is coated with a coating liquid, and the coating time is 30s. After coating, the film is processed in an oven for 120°C for 3 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com