A kind of nico2o4 mesoporous nanotube material grown on carbon fiber cloth and preparation method thereof

A carbon fiber cloth and nanotube technology, which is applied in the field of nanomaterial preparation, can solve the problems of dense accumulation of materials inside the electrode, large internal resistance, unfavorable supercapacitive performance, insufficient electrical conductivity, etc. Charge and discharge utilization efficiency, the effect of enhancing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

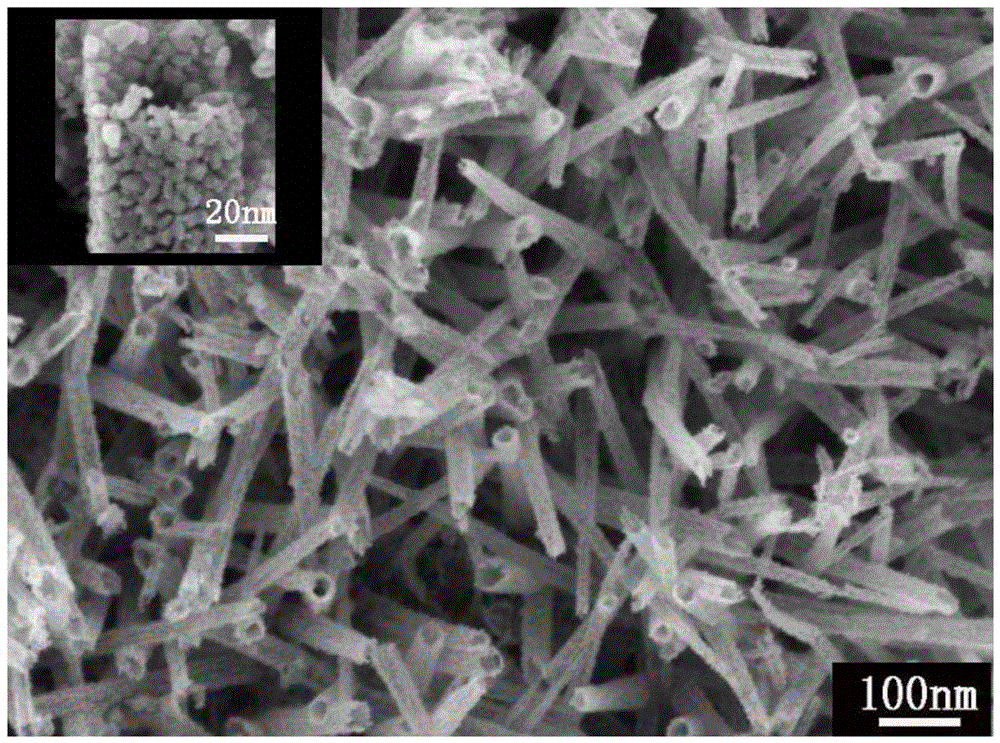

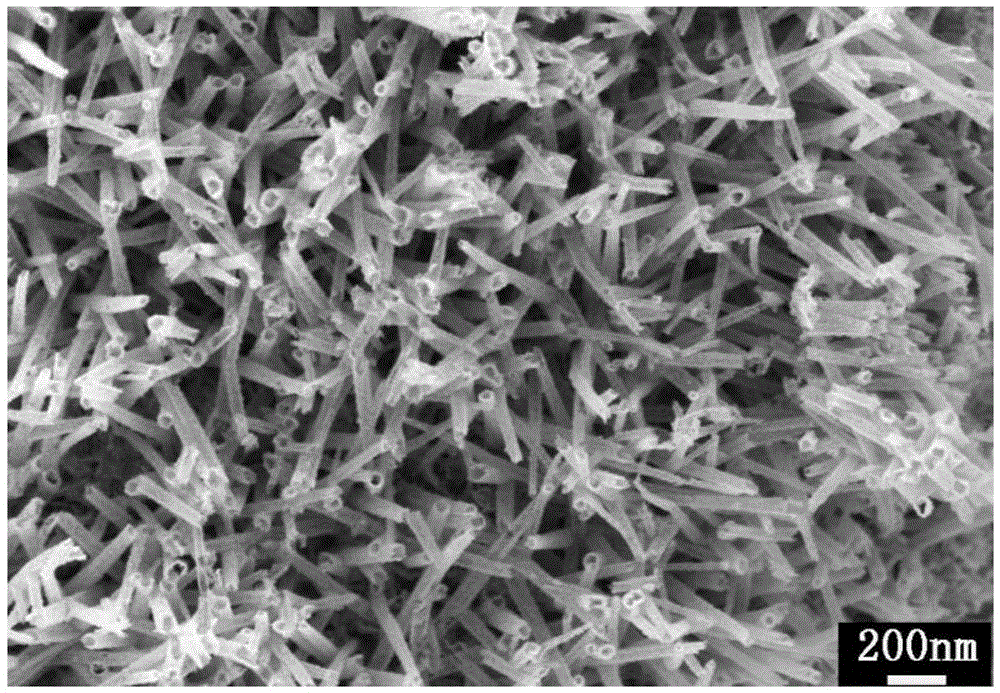

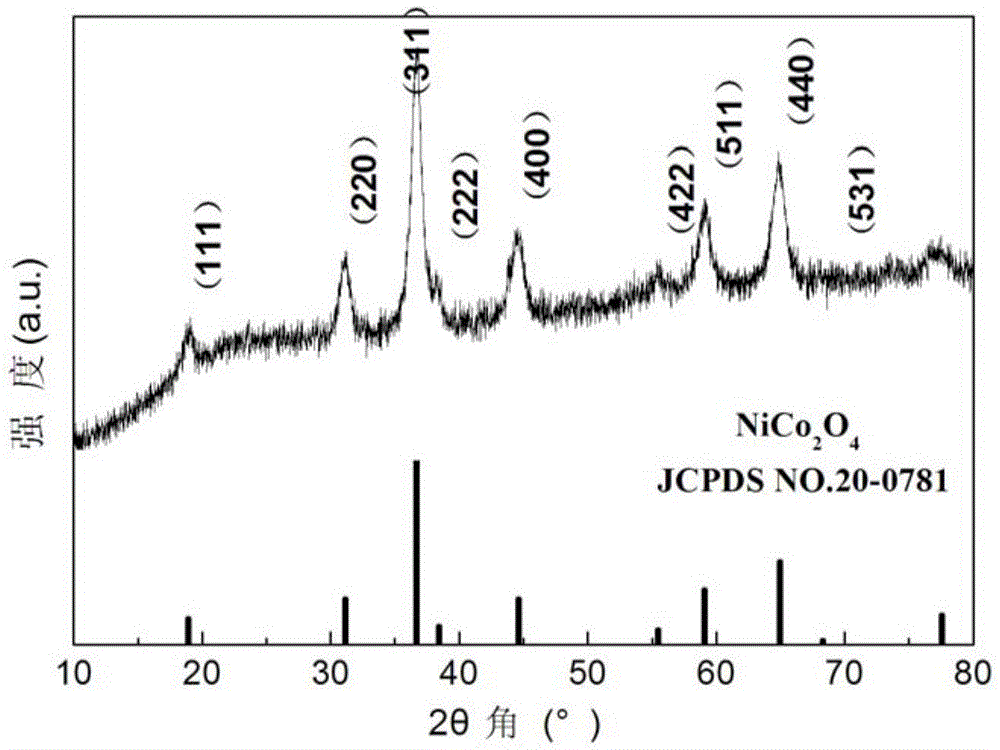

[0023] Take 0.32gNi(NO 3 ) 2 ·6H 2 O, 0.53gCoCl 2 ·6H 2 O, 2.97gCO(NH 2 ) 2 and 1.1gN 4 (CH 2 ) 6 Dissolve in 100mL deionized water until completely dissolved to form a clear pink solution; then transfer 60mL of the solution to a 100mL autoclave, and clean a piece of 2×2cm 2 Place the carbon fiber cloth in the solution, seal the reaction kettle and put it in an oven, heat it to 95°C, hold for 8 hours, take out the carbon fiber cloth after the hydrothermal reaction, wash it with deionized water, dry it at 70°C, and then place it in an inert gas Annealing treatment was carried out in a quartz tube furnace under protection, the heating temperature was 350°C, and the holding time was 3h. After cooling to room temperature, the sample was taken out, and the SEM pattern analysis found that, as figure 1 with 2 As shown, NiCo grown on carbon fiber cloth 2 o 4 It is in the form of nanotubes, the inner diameter of the tube is about 40nm, the wall thickness of the tube is abou...

Embodiment 2

[0025] Take 0.29gNi(NO 3 ) 2 ·6H 2 O, 0.48gCoCl 2 ·6H 2 O, 2.50gCO(NH 2 ) 2 and 1gN 4 (CH 2 ) 6 Dissolve in 100mL deionized water until completely dissolved to form a clear pink solution; then transfer 80mL of the solution to a 100mL autoclave, and clean a piece of 2×2cm 2 Place the carbon fiber cloth in the solution, seal the reaction kettle, put it into the oven, heat it to 100°C, and keep it warm for 8 hours. Take out the carbon fiber cloth after the hydrothermal reaction, wash it with deionized water, dry it at 70°C, and then place it in an inert gas Annealing treatment in a quartz tube furnace under protection, the heating temperature is 380 °C, and the holding time is 2 hours. 2 o 4 The nanocrystalline particle size of the mesoporous nanotube material is about 5-10nm, the mesopore size is about 2-5nm, the tube inner diameter is about 30nm, the tube wall thickness is about 16nm, the tube length is about 0.9μm, and the aspect ratio is about 300.

Embodiment 3

[0027] Take 0.26gNi(NO 3 ) 2 ·6H 2 O, 0.43gCoCl 2 ·6H 2 O, 2.43gCO(NH 2 ) 2 and 0.9gN 4 (CH 2 ) 6 Dissolve in 100mL deionized water until completely dissolved to form a clear pink solution; then transfer 80mL of the solution to a 100mL autoclave, and clean a piece of 2×2cm 2 Place the carbon fiber cloth in the solution, seal the reaction kettle, put it into the oven, heat it to 105°C, keep it for 6 hours, and dry it at 70°C; then place it in a quartz tube furnace under the protection of inert gas for annealing treatment, and the heating temperature is 300°C , the holding time is 6h, the sample is taken out after cooling to room temperature, and its SEM pattern analysis shows that the NiCo grown on the carbon fiber cloth 2 o 4 The nanocrystalline particle size of the mesoporous nanotube material is about 5-10nm, the mesopore size is about 2-5nm, the tube inner diameter is about 20nm, the tube wall thickness is about 12nm, the tube length is 0.6μm, and the aspect ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com