Optical fiber coupling output laser spot homogenizing device and preparation method thereof

A fiber coupling, laser technology, applied in the direction of light guide, optics, instruments, etc., can solve the problem of reducing the flexibility of the laser placement position, and achieve the effect of improving the belt ring, uniform spot, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

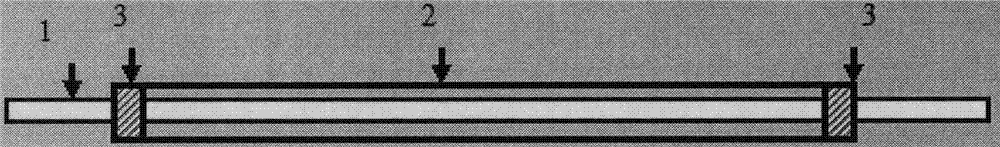

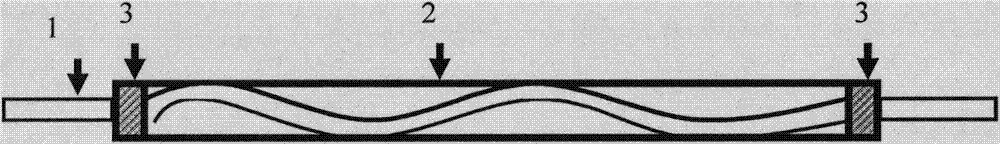

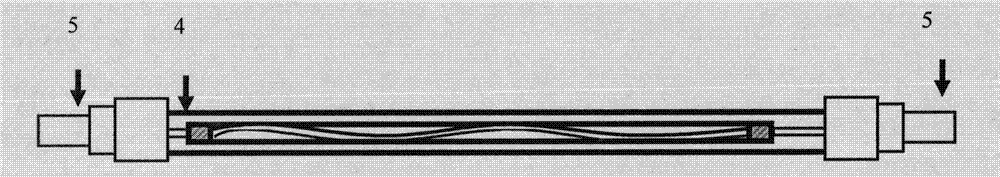

[0044] Such as Figure 1-3 As shown, a fiber-coupled semiconductor laser spot homogenization device includes an optical fiber 1 passing through a flexible tube 2 in the axial direction, and a protective tube 4 coaxially installed with the optical fiber 1 is arranged outside the flexible tube 2 .

[0045] The diameter of the optical fiber 1 is 125 μm.

[0046] In the flexible tube 2 , the optical fiber 1 is installed in the flexible tube 2 perpendicular to the direction of the optical fiber 1 through two fixed ends 3 .

[0047] The fixed end 3 is glue.

[0048] The glue is epoxy resin.

[0049] The flexible tube 2 is a heat-shrinkable tube.

[0050] The flexible pipe 2 is a closed cylinder.

[0051] The protection tube 4 is polyvinyl chloride (ie PVC) material.

[0052] The protective tube 4 is a cylindrical sleeve with armor.

[0053] The diameter of the protective tube 4 is larger than that of the flexible tube 2 .

[0054] Both ends of the protection tube 4 are respec...

Embodiment 2

[0056] A fiber-coupled semiconductor laser spot homogenization device as described in Embodiment 1, the difference is that the diameter of the optical fiber 1 is 220 μm.

[0057] The fixed end 3 is a snap ring.

[0058] The flexible pipe 2 is a PVC pipe with thermal shrinkage properties.

Embodiment 3

[0060] A fiber-coupled semiconductor laser spot homogenization device as described in Embodiment 1, the difference is that the diameter of the optical fiber 1 is 308 μm.

[0061] The flexible pipe 2 is a PVC pipe with thermal shrinkage properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com