Chain transfer near infrared dye and high-molecular polymerization emulsion preparation method and application thereof

A technology of near-infrared dyes and infrared dyes, applied in the field of chain transfer near-infrared dyes and the preparation of polymer emulsions, can solve the problems of reduced product contrast, insufficiently uniform dye dispersion, poor light stability of dyes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

[0065] Example 1 Synthesis of near-infrared dyes using 1,6-hexanedithiol as chain transfer reagent and preparation of polymerized heat-sensitive polymer emulsion

[0066] (1) Preparation of thermosensitive near-infrared dyes capable of chain transfer

[0067] Add 6 grams of near-infrared dye, 5.96 grams of 1,6-hexanedithiol and 4 grams of triethylamine into a single-port bottle, wherein, near-infrared dye: 1,6-hexanedithiol: triethylamine (molar ratio) 1 :5:5, add 50 ml of N,N dimethylformamide, stir and mix and react at 25°C under nitrogen protection for 24 hours. Centrifuge at a speed of 1 / min and collect the solid dye after drying.

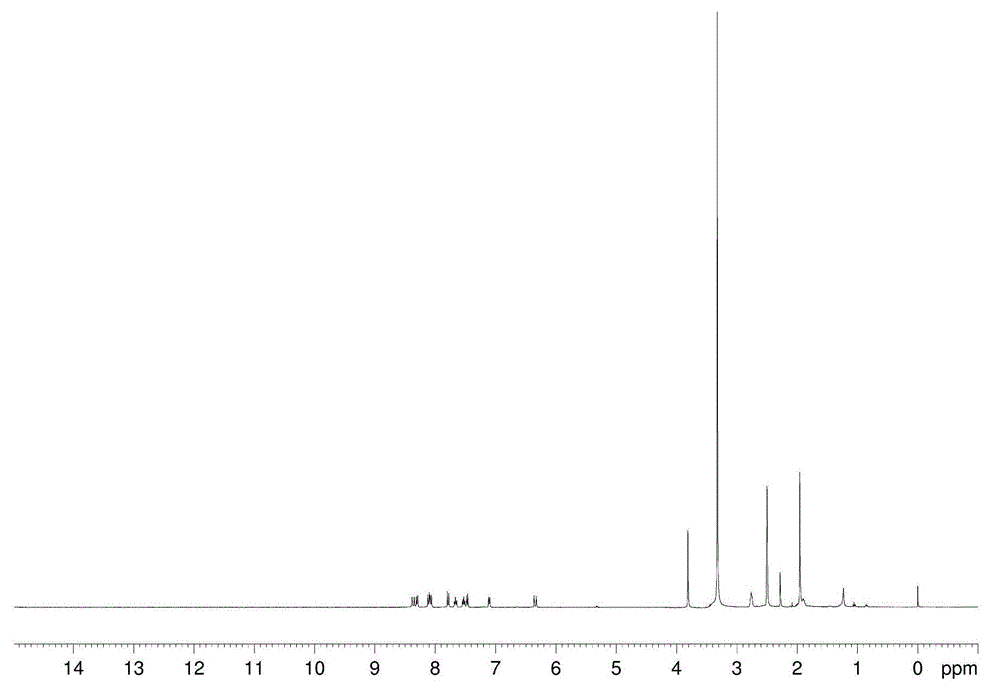

[0068] Such as figure 2 Shown is the NMR image of the chain-transferable infrared dye of Example 1.

[0069] The reaction equation of above-mentioned preparation dye monomer is as follows:

[0070]

[0071] (2) Preparation of polymerized thermosensitive polymer emulsion

[0072] The oil phase is prepared by dissolving 5 grams of the ab...

Embodiment 21

[0081] Example 2 Synthesis of near-infrared dyes using 1,2-ethanedithiol as a chain transfer agent and preparation of polymerized thermosensitive polymer emulsion

[0082] (1) Preparation of thermosensitive near-infrared dyes capable of chain transfer

[0083] Add 6 grams of near-infrared dye, 7.47 grams of 1,2-hexanedithiol and 8 grams of triethylamine into a single-port bottle, wherein, near-infrared dye: 1,2-ethanedithiol: triethylamine (molar ratio) 1 :10:10, add 50 milliliters of N,N dimethylformamide, stir and mix and react for 12 hours under nitrogen protection at 25°C, after the end, add a large amount of ether to the flask for stirring and washing. Centrifuge at a speed of 1 / min and collect the solid dye after drying.

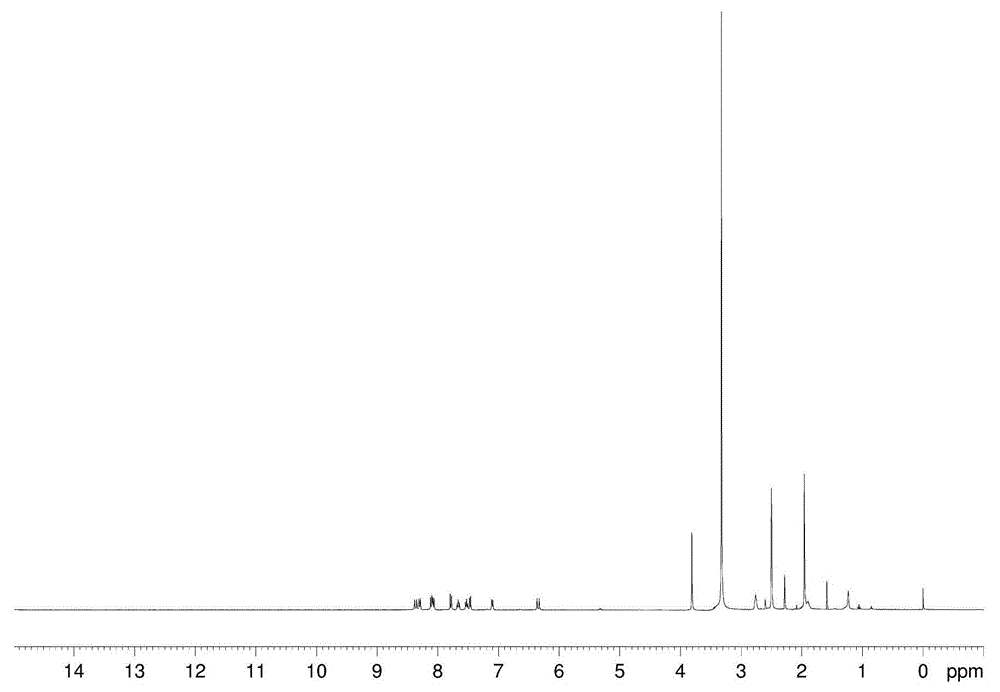

[0084] Such as image 3 Shown is the NMR map of the chain-transferable infrared dye of Example 2.

[0085] The reaction equation of above-mentioned preparation dye monomer is as follows:

[0086]

[0087] (2) Preparation of polymerized thermosen...

Embodiment 3

[0092] Example 3 Synthesis of near-infrared dyes using 2,3 dimercaptosuccinic acid as chain transfer reagent and preparation of polymerized heat-sensitive polymer emulsion

[0093] (1) Preparation of thermosensitive near-infrared dyes capable of chain transfer

[0094] Add 6 grams of near-infrared dye, 2.15 grams of 2,3 dimercaptosuccinic acid and 0.6 grams of triethylamine into a one-mouth bottle, wherein, near-infrared dye: 2,3 dimercaptosuccinic acid: triethylamine (molar ratio) 1:1.5:1.5, add 50 ml of N,N dimethylformamide, stir and mix and react at 25°C under nitrogen protection for 24 hours. Centrifuge at a speed of 1 rpm, and collect the solid dye after drying.

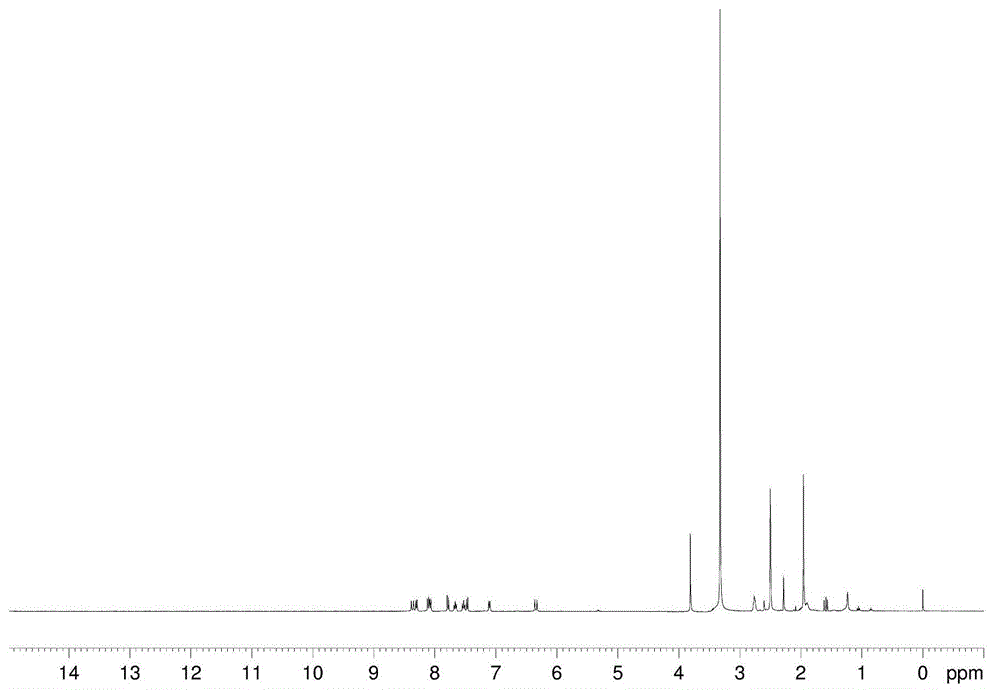

[0095] Such as Figure 4 Shown is the NMR image of the chain transfer infrared dye of Example 3.

[0096] The reaction equation of above-mentioned preparation dye monomer is as follows:

[0097]

[0098] (2) Preparation of polymerized thermosensitive polymer emulsion

[0099] Prepare the oil phase, diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com