Camellia oil with full-bodied sauce flavor and preparation method thereof

A camellia oil and flavor technology, which is applied in the direction of fat oil/fat refining, edible oil/fat, and fat oil/fat production, etc., can solve the problems of inability to form and bring out the aroma compounds of camellia oil, loss of camellia oil flavor, and food safety issues. , to achieve the specific and reasonable effect of the program cooling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

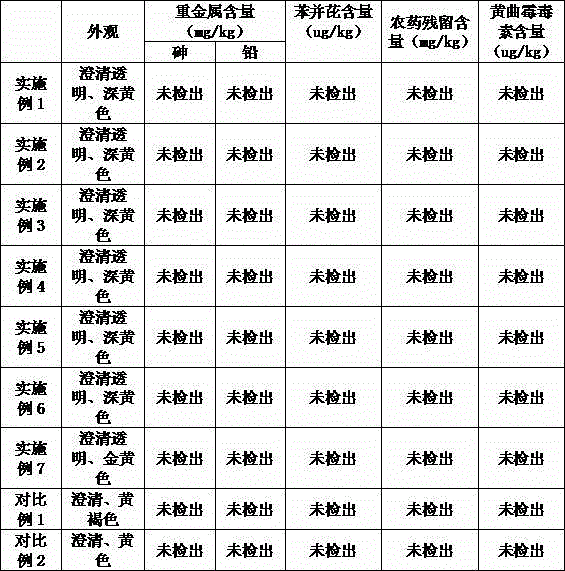

Embodiment 1

[0046] A kind of camellia oil with rich sauce flavor was prepared by the following method:

[0047] A. Preparation of tea seed kernels: take fresh tea seeds of that year, spread them out to dry naturally, so that the water content of the tea seeds is controlled at 10-20% by mass; remove the husks of the tea seeds to obtain the tea seed kernels;

[0048] B. Making fermented husks:

[0049] Lay the fruit husks obtained in step A indoors, pack them in mesh bags at a height of 1.5 meters, ventilate, and stack them for 5 days; the tea berries produce a special flavor, spread them out to dry naturally, and then remove surface dust or possible contamination Harmful substances, fermented husks were obtained, and crushed into pieces within 2 cm by a crusher;

[0050] C. Ripening: Add 1200 kg of fermented husks obtained in step B to 10,000 kg of camellia seed kernels obtained in step A, the fermented husks account for 10.7% by mass of the total amount, mix evenly to obtain a mixture of...

Embodiment 2

[0056] Using the method basically the same as that of Example 1, the camellia oil with strong sauce-flavored flavor of Example 2 was prepared. The main differences include: in the step B of making fermented husks, the high-quality fresh camellia oleifera fruit is directly peeled to obtain fresh husks; Put it in a special place where the rain can't get out, the thickness is less than 20 cm, ventilated, and the stacking time is 7 days; the husk produces a special flavor, removes the surface dust or harmful substances that may be polluted, and makes the fermented husk, and passes through the crusher Broken into pieces within 2 cm;

[0057] In step C, 10,000 kg of camellia seed kernels are added with 4,000 kg of fermented husks, the husk content is 28.6% by mass, the roasting temperature is 130°C, and the pressing chamber temperature in step D is 110°C; in step E, the shell oil mixture contains 20% by mass of camellia oil, and when pressed The temperature of the pressing chamber i...

Embodiment 3

[0061] Using the method basically the same as that of Example 1, the camellia oil with strong sauce-flavored flavor of Example 3 was prepared. The main differences include: in step C, 10,000 kg of camellia seed kernels were added with 3,000 kg of fermented husks, the husk content was 23.1% by mass, and roasted The temperature is 140°C, the temperature of the pressing chamber in step D is 120°C, the mixture of shell oil in step E contains 25% by mass of camellia oil, the temperature of the pressing chamber during pressing is 120°C, and the mixture of shell oil in step E contains 8.5% by mass of water; other conditions are the same .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com