Piezoelectric polymer/metal composite nano-filament and preparation method thereof

A piezoelectric polymer and metal composite technology, applied in the direction of conjugated synthetic polymer artificial filament, fiber treatment, fiber chemical characteristics, etc., can solve the problems of poor biocompatibility, poor plasticity, etc., achieve high development prospects, improve The effect of refinement and power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

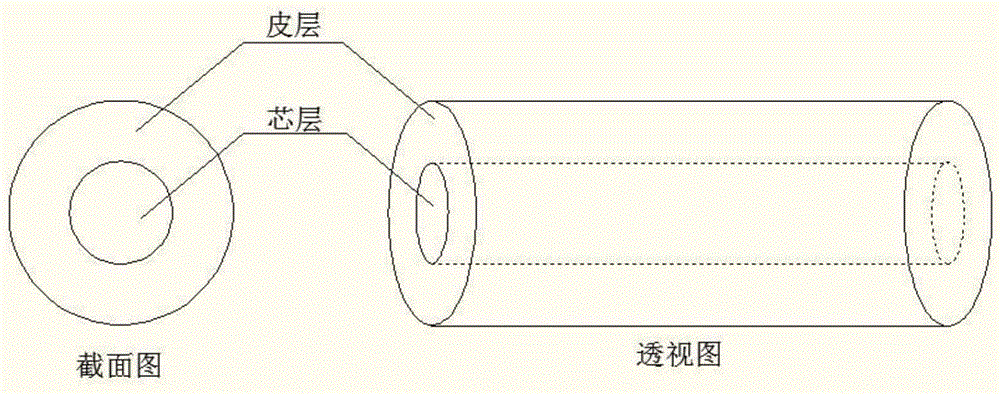

[0023] Weigh 100 μmol of ferric chloride hexahydrate, dissolve it in a compound solution of 10.8g DMF and 7.2g acetone, and dissolve it completely; then weigh 2g of polyvinylidene fluoride and dissolve it in the above solution, and heat it at 75°C Heating and dissolving to obtain a uniform and transparent solution, and then the solution is subjected to an electrospinning process to coat the polymer nanofibers on the surface of the metal wire. The parameters of the electrospinning process are: voltage: 8kV; receiving distance: 25cm; extrusion speed : 1.0ml / h. Finally, the obtained composite fiber was placed in a ventilated environment at 25° C. for 48 hours to complete the preparation.

[0024] In the obtained composite electrical fiber, the core layer copper wire and the skin layer polyvinylidene fluoride fiber have good adhesion, relatively tight adhesion, uniform thickness, slightly yellowish color, good piezoelectric performance, and a piezoelectric voltage of 0.12V / cm. ...

Embodiment 2

[0026] Weigh 58.3 μmol of copper chloride dihydrate, dissolve it in a compound solution of 10.8g DMF and 7.2g acetone, and make it completely dissolved; then weigh 2g of polyvinylidene fluoride and dissolve it in the above solution, and heat Under heating and dissolving, a uniform and transparent solution is obtained, and then the solution is subjected to an electrospinning process to coat the polymer nanofibers on the surface of the metal wire. The electrospinning process parameters are: voltage: 15kV; receiving distance: 15cm; extrusion Speed: 1.5ml / h. Finally, the obtained composite fiber was placed in a ventilated environment at 25° C. for 48 hours to complete the preparation.

[0027] In the obtained composite piezoelectric fiber, the core layer copper wire and the skin layer polyvinylidene fluoride fiber have good adhesion, the adhesion is relatively tight, the thickness is uniform, the color is slightly blue-green, and the piezoelectric performance is good. The piezoele...

Embodiment 3

[0029] Weigh 1.6g of polyvinylidene fluoride, dissolve it in a compound solution of 10.8g DMF and 7.2g acetone, heat and dissolve it at 75°C to obtain a uniform and transparent solution, and then carry out the electrospinning process of the solution, The polymer nanofibers are coated on the surface of the wire, and the electrospinning process parameters are: voltage: 20kV; receiving distance: 20cm; extrusion speed: 0.5ml / h. Finally, the obtained composite fiber was placed in a ventilated environment at 25° C. for 48 hours to complete the preparation.

[0030] In the obtained composite piezoelectric fiber, the core layer copper wire and the skin layer polyvinylidene fluoride fiber have poor adhesion, the skin layer fiber is thinner, and the structure is fluffy, the thickness is uniform, and the piezoelectric voltage is 0.04V / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com