Method for utilizing combined structure to conduct shield tunnel strengthening

A technology of shield tunnel and combined structure, applied in tunnels, tunnel linings, mining equipment and other directions, can solve the problems of I-beams occupying a large headroom, easily unstable under pressure, not very optimistic, etc., and achieves good temperature resistance performance. , Improve safety and reliability, and enhance the effect of reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

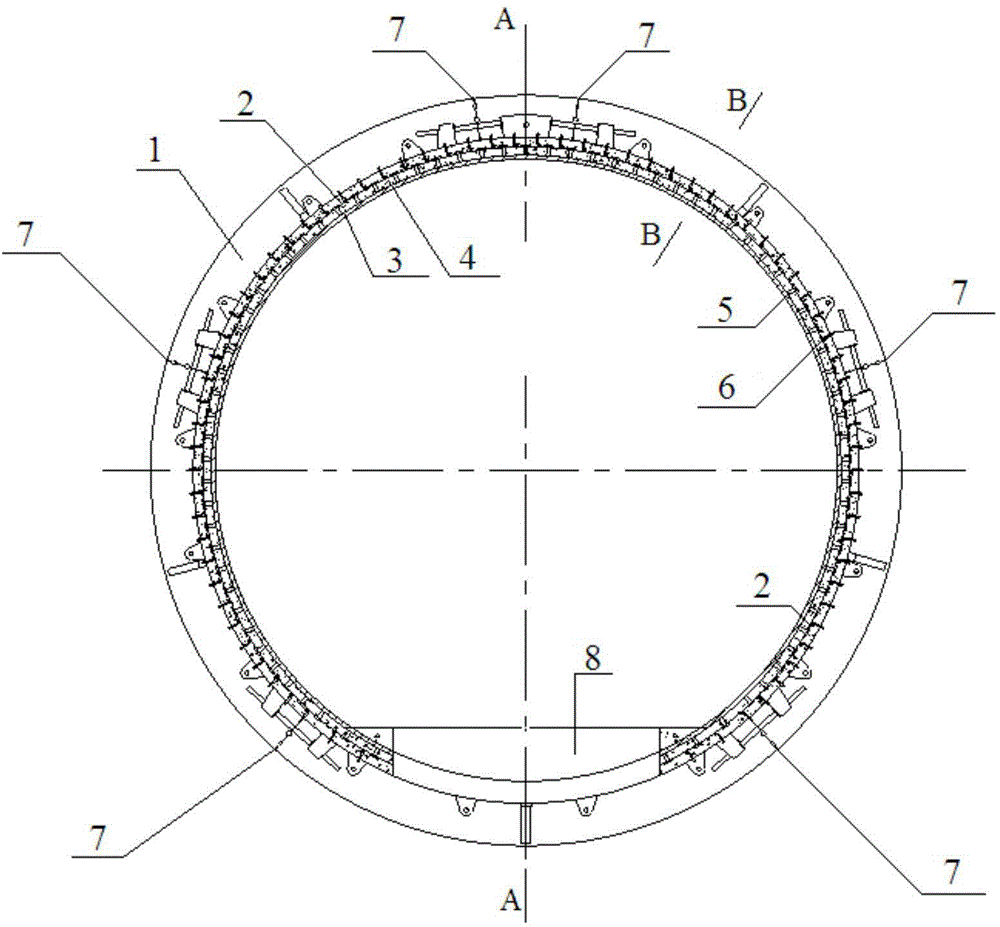

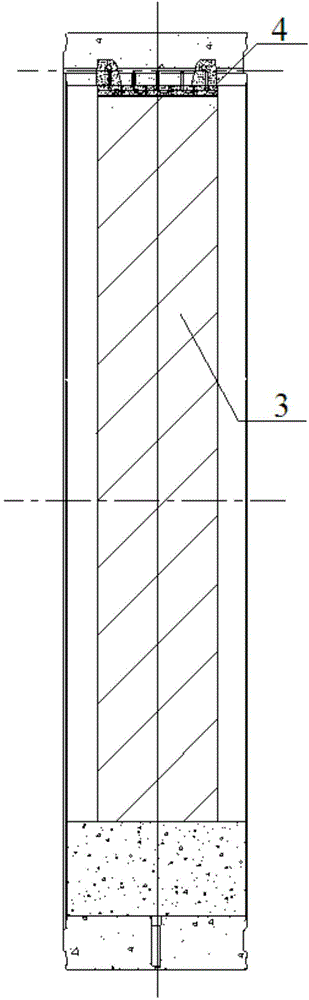

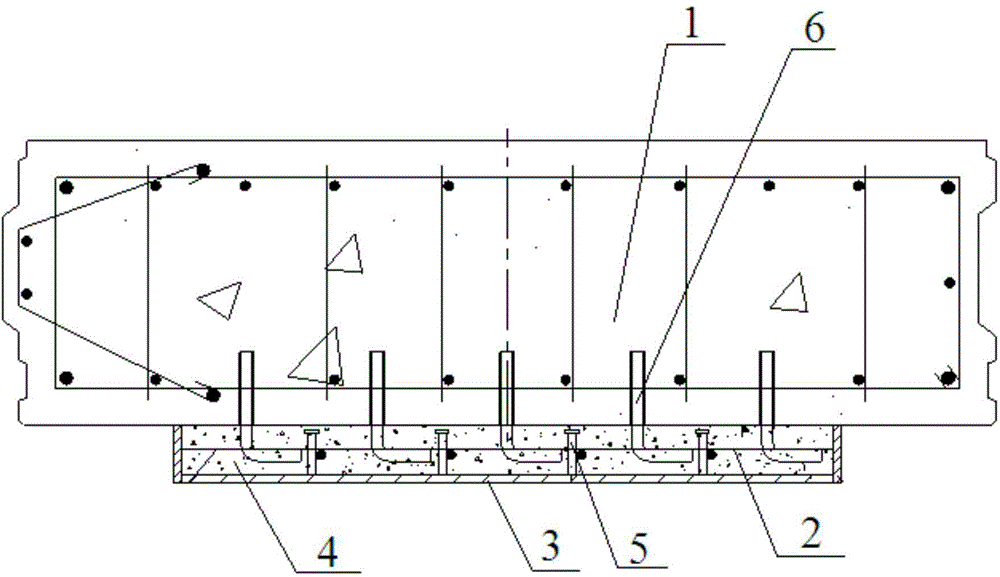

[0038] refer to Figure 1 ~ Figure 3 , a method for shield tunnel reinforcement using a composite structure, comprising the following steps:

[0039] (1) Chisel the inner surface of the original segment 1 of the tunnel, and use planting glue to plant bars according to a certain distance. Each ring segment is divided into 3-4 rows of planting bars, in order to avoid excessive weakening of the same section Each row of planting bars 6 is staggered laterally (to ensure that no more than two planting bars 6 appear in the same section) or arranged in a quincunx shape, wherein one end of planting bars 6 protruding from the original tunnel segment 1 is provided with a hook. The advantage of using planting glue is that it has high bonding strength, like pre-embedding, curing at room temperature, small shrinkage during hardening, good temperature resistance, can be welded after embedding, good durability, weather resistance, aging resistance, and medium resistance (acid, alkali, water)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com