High-water-content biomass fuel boiler

A biomass fuel, high water content technology, applied in the combustion of solid fuel, combustion method, combustion equipment and other directions, can solve the problems of difficult combustion, low thermal efficiency, smoke exhaust affects the environment, etc. The effect of high furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

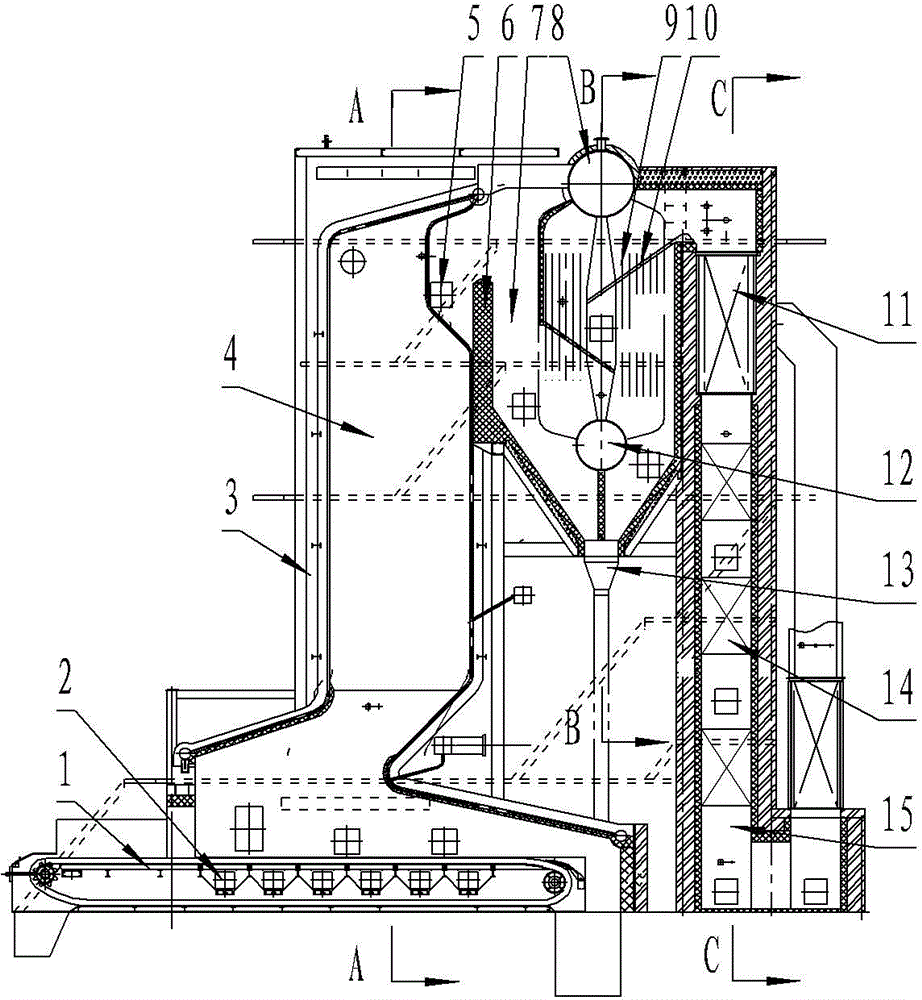

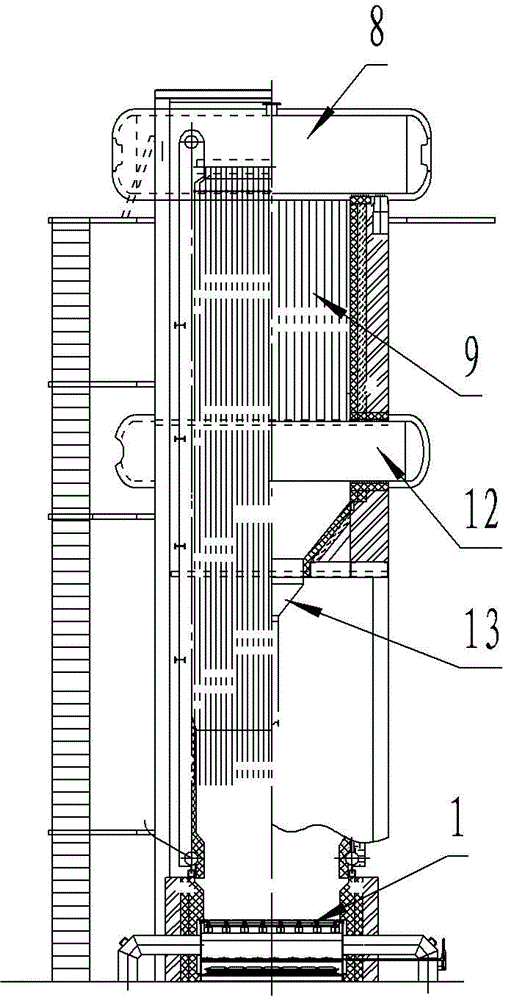

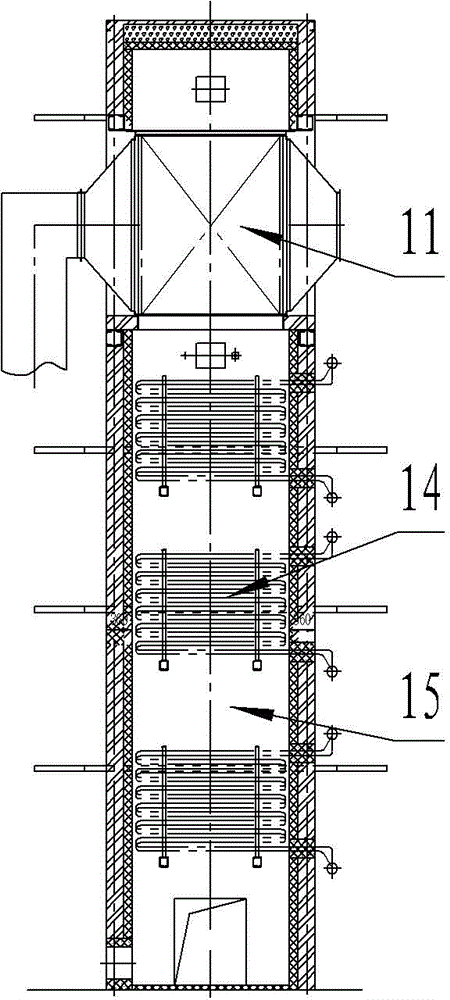

[0016] like figure 1 , figure 2 , image 3 The shown high water content biomass fuel boiler includes a furnace hearth and a flue 15, and a plurality of headers 5 are arranged on the walls of the furnace hearth and the flue 15.

[0017] The furnace wall of the furnace is a water-cooled film-type wall 3 with a cold water pipe, and an uncapped partition wall 6 is arranged in the furnace, and the upper part of the partition wall 6 is made of heat-resistant bricks. The water-cooled membrane wall 3 and the partition wall 6 at the front of the furnace form a front supply area 4, and the water-cooled membrane wall 3 and the partition wall 6 at the rear of the furnace form a rear supply area 7, and the lower part of the front supply area 4 is provided with a chain grate. 1. The front supply area 4 is provided with six air distribution ports 2 along the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap