Heating furnace system energy saving method for alkylbenzene integrated unit

A combined device and heating furnace technology, which is applied in the application field of process technology, can solve the problems of uneconomical waste heat boiler technology, complex heat exchange process, and large floor space, and achieves small floor space, simple process, and variable floor space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

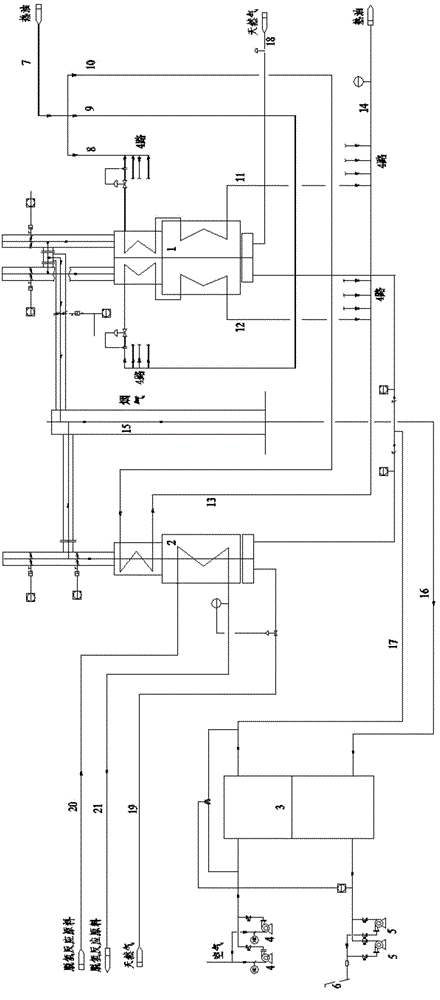

Embodiment 1

[0036] For hot oil with a temperature of 279°C, a pressure of 1.1MPa, and a total flow rate of 889,032kg / h, the above-mentioned heating furnace system of the combined alkylbenzene unit is used, and the hot oil with a flow rate of 100,000kg / h is used to dehydrogenate the second convection section of the heating furnace Exchange heat with high-temperature flue gas at 565°C, take heat of 212MW, heat oil temperature rises to 320°C, and flue gas temperature drops to 331°C; use flow control eight hot oil to heat oil heating furnace 1, each flow is 98629kg / h, heated by the thermal oil heating furnace 1, the temperature of the thermal oil rises to 320°C, the temperature of the flue gas drops to 299°C, the heat load of the thermal oil heating furnace 1 is 20.31MW, and the heated thermal oil converges at the outlet of the thermal oil heating furnace 1 , the natural gas fuel quantity of thermal oil heating furnace 1 is controlled by the outlet thermal oil temperature to be 1618kg / h; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com