Manufacturing method of printed circuit boards with optical waveguide couplers

A printed circuit board and optical waveguide coupling technology, which is applied in the coupling of optical waveguides, optical waveguides and light guides, etc., can solve the problems of difficult process, poor alignment accuracy, and difficulty in mass production, and achieve a smooth and flat surface of the micromirror. , The effect of high alignment accuracy and small micromirror size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0049] see Figure 1 to Figure 10 , taking the production of a printed circuit board containing one optical waveguide layer and four copper layers as an example, the process flow is as follows:

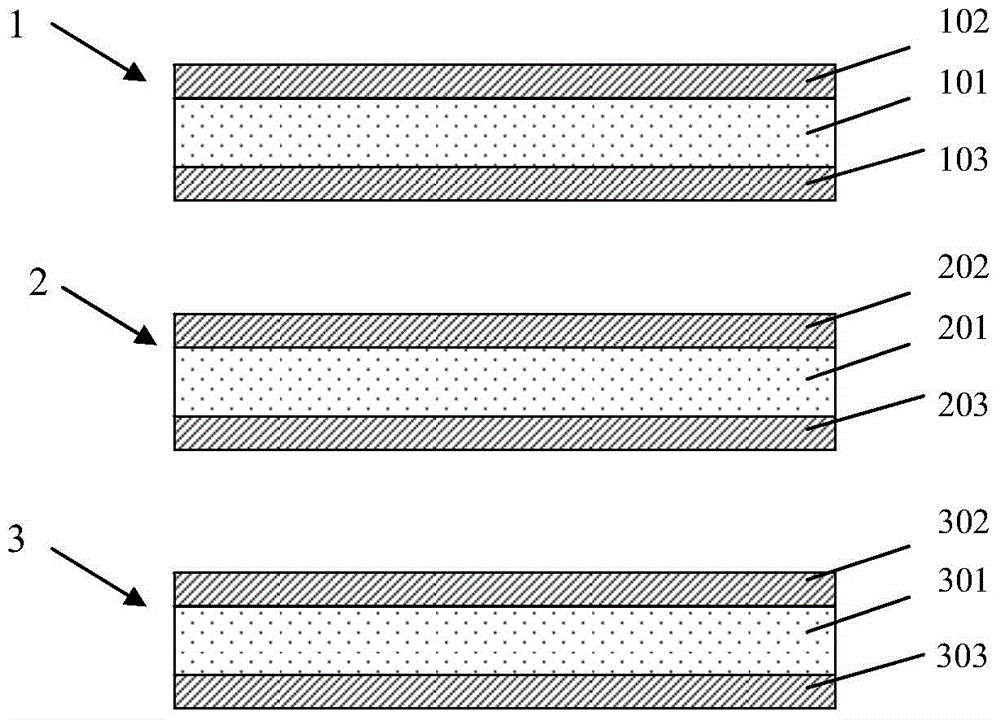

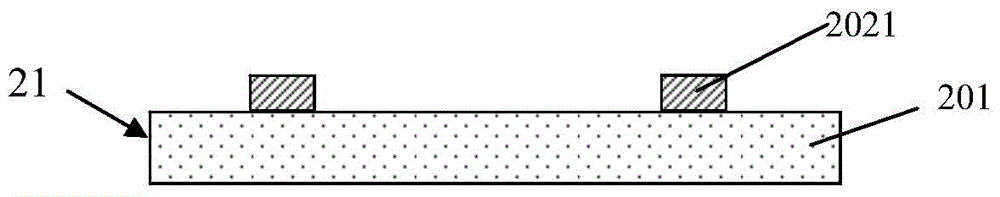

[0050] 1) Substrate production, 1, 2, and 3 are cut copper-clad laminates, copper-clad laminates 1 and 3 are used for the production of two second-layer copper layers, and the copper-clad laminate 2 located in the middle is used for the production of the optical waveguide layer. Among them, 101, 301 are dielectric layers, 102, 103, 302, 303 are copper layers, see figure 1 ; The optical waveguide substrate 21 is a copper-clad laminate that etches away most of the copper, and this substrate leaves a copper surface (copper barrier layer) 2021 in the subsequent fabrication of the optical waveguide micromirror region, see figure 2 .

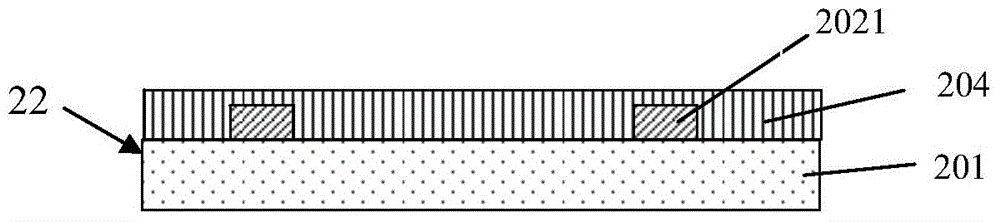

[0051] 2) making the optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com