X-ray target assembly

A target assembly, X-ray technology, used in X-ray tube parts, X-ray/γ-ray/particle irradiation therapy and other directions, can solve the problems of easy corrosion, poor heat dissipation, unusable, etc., to prevent oxidation and The effect of surface corrosion, increasing X-ray dose rate and increasing incident power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

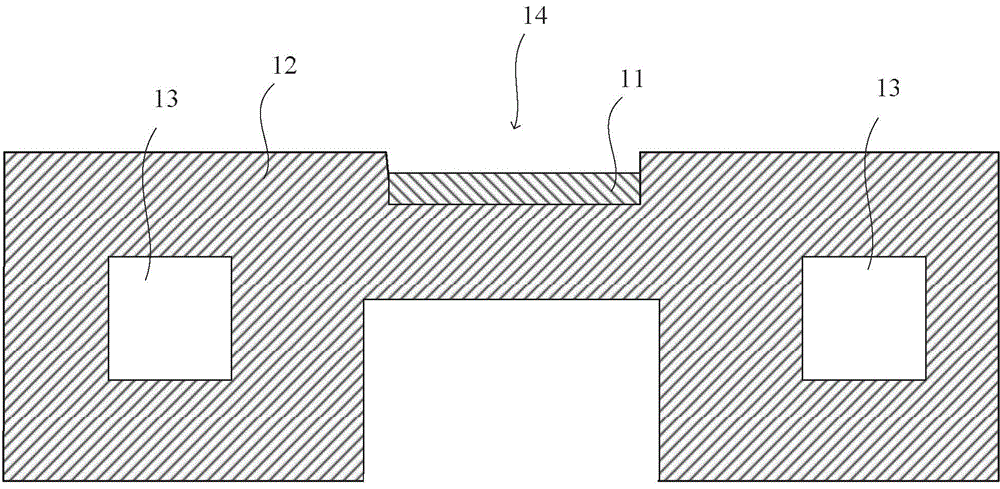

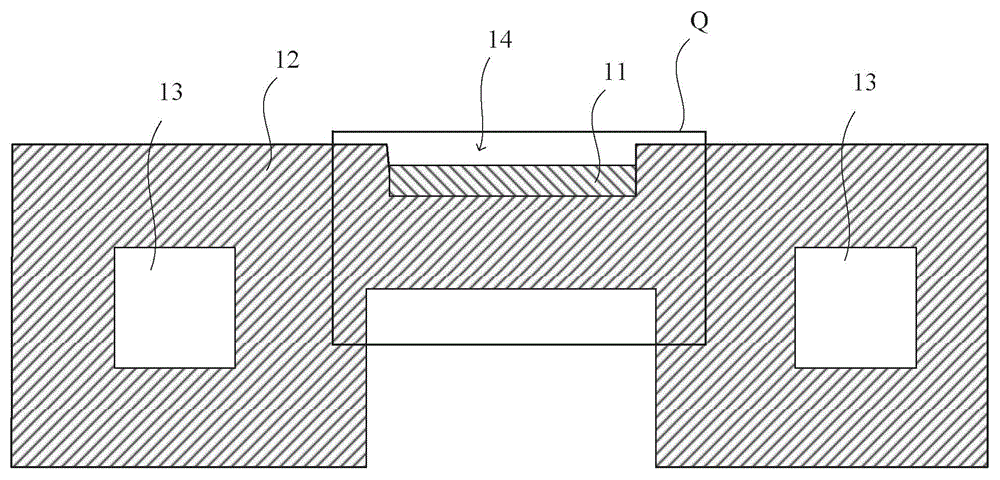

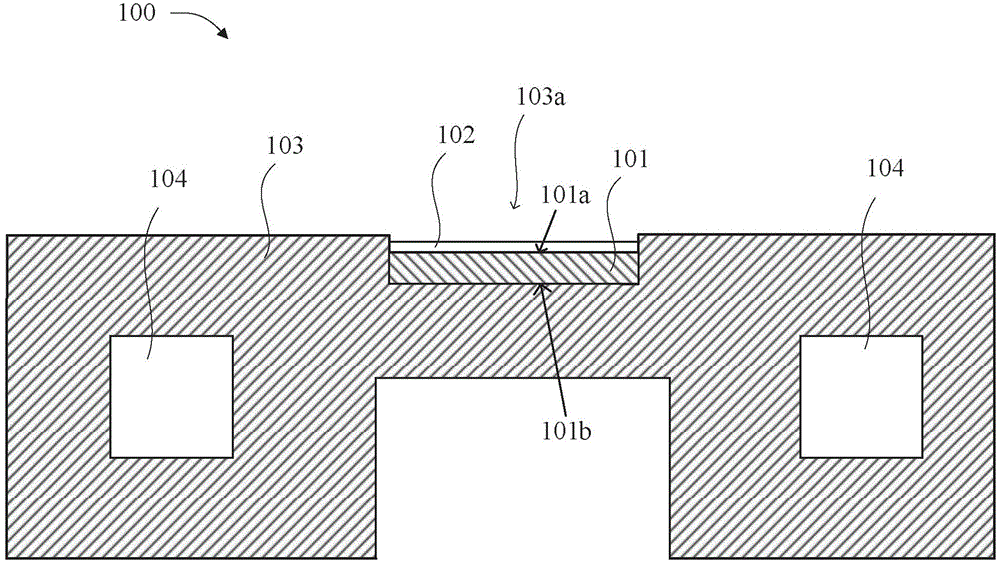

[0031] This embodiment provides an X-ray target assembly 100, refer to image 3 , including a target 101 , a heat conduction layer 102 and a heat dissipation part 103 .

[0032] combine Figure 4-5 As shown, the target 101 has a first surface 101a receiving high-energy electron beam bombardment, and a second surface 101b opposite to the first surface 101a, the first surface 101a has a bombarded part A, and the heat conduction layer 102 covers the first surface 101a And stick to the first surface 101a.

[0033] The heat conduction layer 102 is a key component in the structure of this embodiment. Theoretically, the selection conditions for the material of the heat conduction layer 102 are: the larger the thermal conductivity, the better, the lower the density, the better, and the smaller the thickness. In this embodiment, the material of the thermal conduction layer 102 is graphite or a modified graphite material.

[0034] The cooling part 103 is made of heat-conducting metal...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that, referring to Figure 4-5 and combine Figure 8 As shown, the thermal conduction layer 102 structurally includes a base layer 102a and an anti-oxidation layer 102b, and the base layer 102a is at least one of beryllium, iron, or modified materials of beryllium and iron.

[0050] Wherein, the base layer 102a is at least bonded to the bombarded part A, and the anti-oxidation layer 102b is located on the side of the base layer 102a opposite to the bombarded part A, covers the base layer 102a and is bonded to the base layer 102a.

[0051] If the modified material of beryllium and iron used as the base layer 102a has oxidation resistance, the anti-oxidation layer 102b can be omitted.

[0052] In order to reduce the influence of the heat conduction layer 102 on the beam spot and energy spectrum of the incident electron beam, the heat conduction layer 102 needs to meet at least: the thermal conductivity of the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com