Method for synthesizing graphene/nickel nano-composite material at room temperature

A technology for nanocomposite materials and synthetic graphite, which is applied in the field of synthesis of graphene and nickel nanocomposite materials, can solve the problems of complex post-treatment process, toxic and side effects of raw materials, large energy consumption, etc., achieve good reduction effect, easy process control, The effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Dissolve 0.020g of graphene oxide in 20mL of deionized water, and disperse it ultrasonically for 1.5h at a power of 150W to obtain a graphene oxide solution;

[0031] 2) Add 0.20g of nickel chloride hexahydrate powder to the graphene oxide solution prepared in step 1), continue to process for 1h under ultrasonic conditions of 150W power, mix well, and obtain a mixed solution;

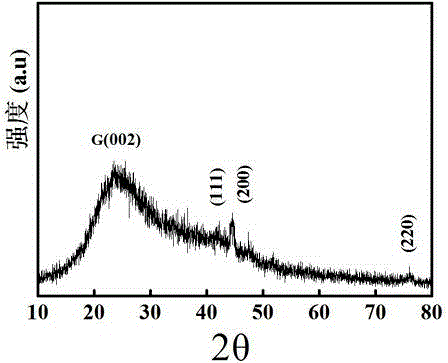

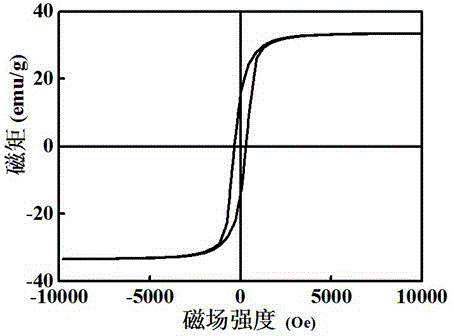

[0032] 3) Dissolve 0.20g of sodium borohydride powder in 5mL of deionized water, and inject it dropwise into the mixed solution prepared in step 2) with a syringe (0.5mL each time, with a dropping rate of 2 drops / min), ultrasonically assisted Carry out the reduction reaction, the ultrasonic power is 150W, and the ultrasonic time is 20min; after the reaction is completed, the black magnetic powder is washed 3 times with deionized water, and then the black magnetic powder is separated by a magnet, and dried in vacuum (101kPa) at room temperature for 36h to obtain graphite ene / nickel nanocomposit...

Embodiment 2

[0041] 1) Dissolve 0.010g of graphene oxide in 20mL of deionized water, and disperse it ultrasonically for 1 hour at a power of 100W to obtain a graphene oxide solution;

[0042] 2) Add 0.10 g of nickel nitrate hexahydrate powder to the graphene oxide solution prepared in step 1), and continue to process for 30 min under ultrasonic conditions of 100W power to obtain a mixed solution;

[0043]3) Dissolve 0.50g of potassium borohydride powder in 5mL of deionized water, and inject it dropwise into the mixed solution prepared in step 2) with a syringe (0.5mL is added dropwise at a rate of 5 drops / min), ultrasonically assisted Carry out the reduction reaction, the ultrasonic power is 100W, and the ultrasonic time is 10min; after the reaction is completed, wash with ethanol twice, rinse the black magnetic powder once with deionized water, then use a magnet to separate the black magnetic powder, and vacuum it at room temperature (50KPa) dry 12h, obtain graphene / nickel nanocomposite m...

Embodiment 3

[0046] 1) Dissolve 0.015g of graphene oxide in 20mL of deionized water, and disperse it ultrasonically for 70min at a power of 130W to obtain a graphene oxide solution;

[0047] 2) Add 0.15g nickel acetate tetrahydrate powder to the graphene oxide solution prepared in step 1), and continue to process for 40min under ultrasonic conditions of 130W power to obtain a mixed solution;

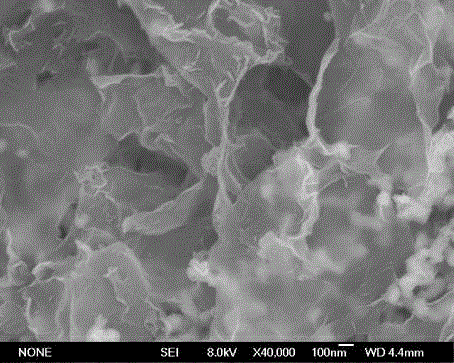

[0048] 3) Dissolve 0.30g of sodium borohydride powder in 5mL of deionized water, and inject it dropwise into the mixed solution prepared in step 2) with a syringe (0.5mL each time, with a dropping rate of 4 drops / min), ultrasonically assisted Carry out the reduction reaction, the ultrasonic power is 130W, and the ultrasonic time is 15min; after the reaction is completed, wash the black magnetic powder with deionized water for 3 times, then use a magnet to separate the black magnetic powder, and dry it in vacuum (80KPa) at room temperature for 24h to obtain graphite ene / nickel composite, its SEM image...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Reversible charge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com