Closed small gap multi-electrode gas switch device and method

A gas switch and small gap technology, which is applied in the direction of electronic switches, measuring devices, electrical components, etc., can solve the problems of reducing the volume and weight of the gas switch, reducing the insulation distance, poor synchronization, etc., achieving a wide trigger range, improving applicability, The effect of reducing the distance between the ball gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

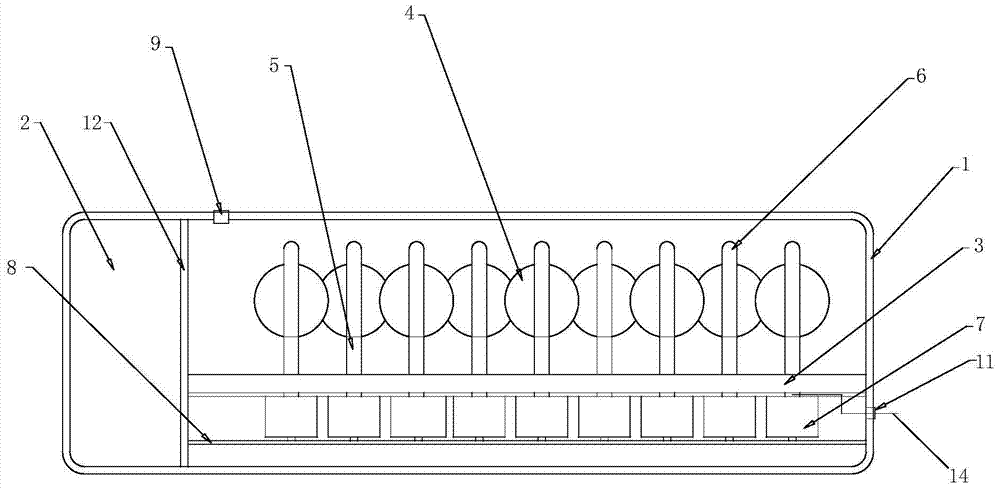

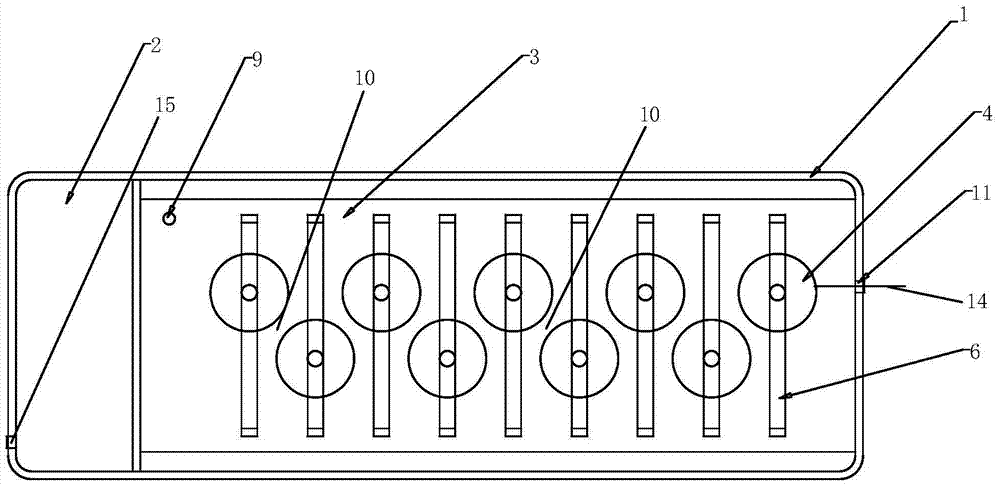

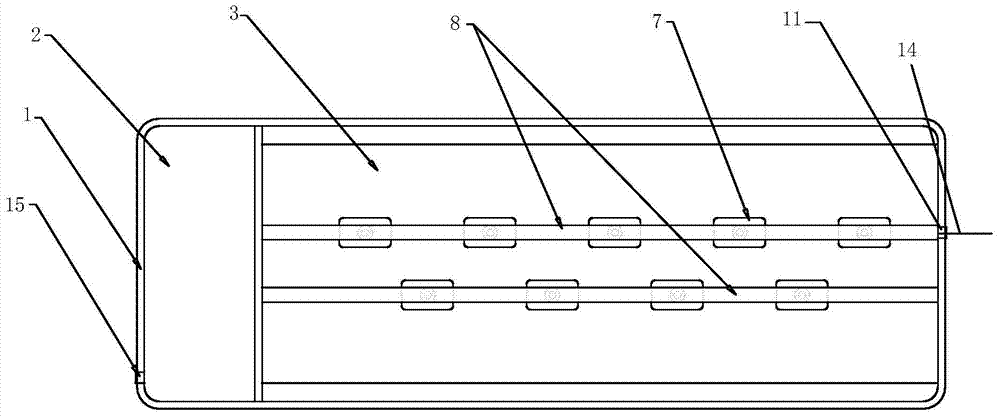

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0024] A closed small-gap multi-electrode gas switch device designed by the present invention adopts a sealed structure and is filled with sulfur hexafluoride gas with good insulation performance, which can greatly reduce the size of the internal electrodes and the gap between the electrodes. , so as to reduce the volume of the whole device; moreover, this device can adjust the rated voltage of the switch device through the inflation air pressure, so as to avoid the phenomenon of manufacturing different abrasive tools and making multiple times for products with little change; at the same time, this device adopts spherical electrodes, through The conductive parts inside the insulating pillars are connected to form a discharge gap. The electric field distribution of this arrangement is more uniform (the shape of the spherical electrode is more regu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com