Preparation method of anti-adhesion polypropylene mesh coated with polydopamine for abdominal wall defect repair and obtained mesh material

A polypropylene mesh, polydopamine technology, applied in the coating and other directions, can solve the problems of perforation of the digestive tract, many preparation requirements, complicated processes, etc., and achieves good hydrophilicity and biocompatibility, and the production process is simple and reduced. The effect of intestinal adhesions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

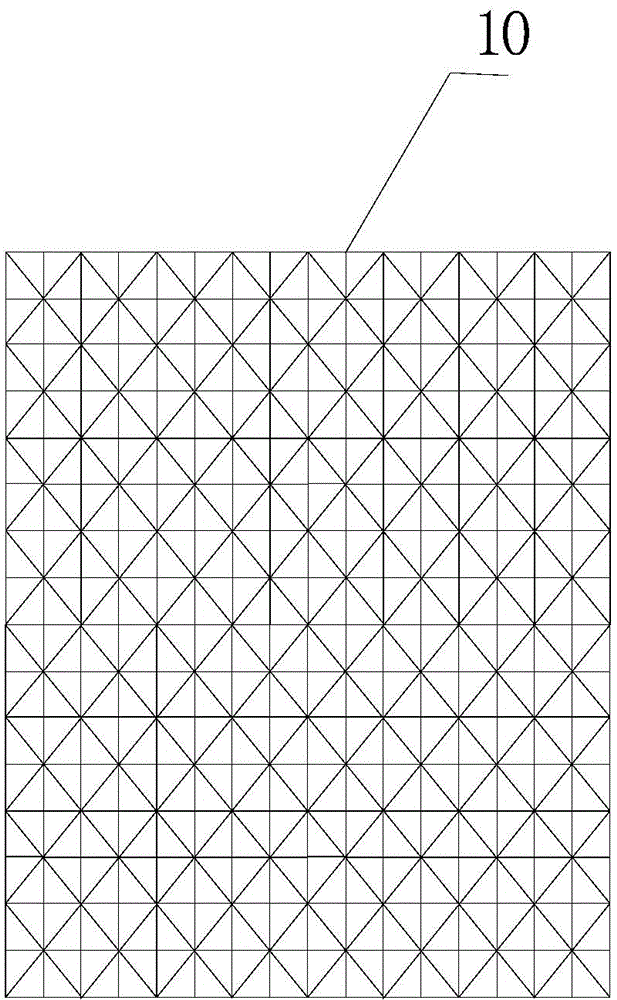

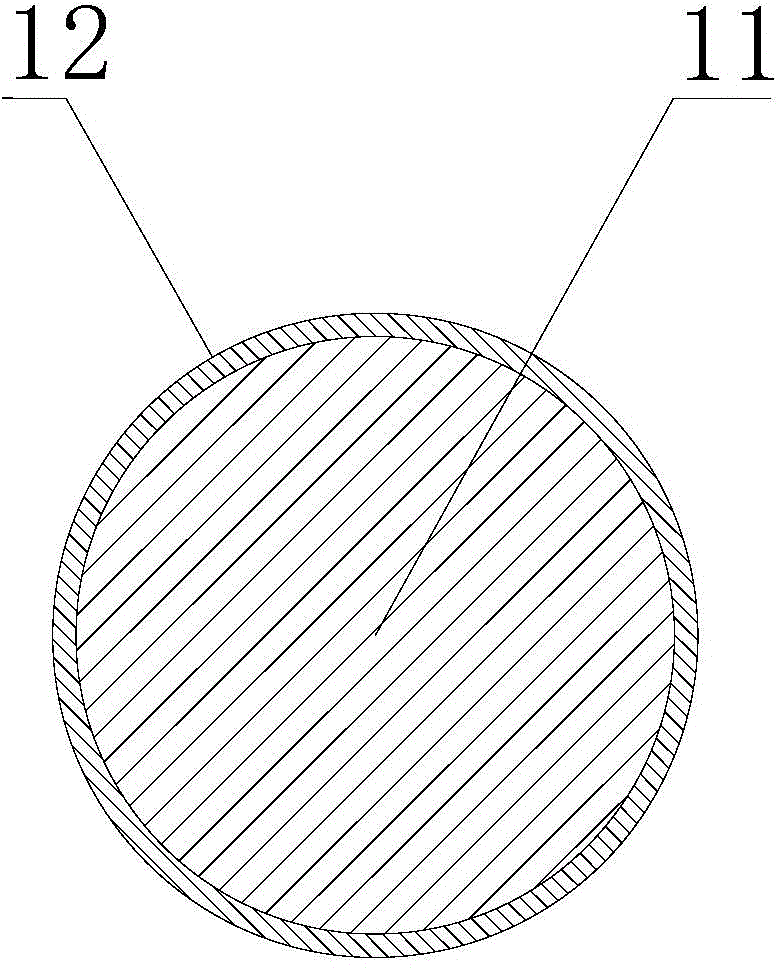

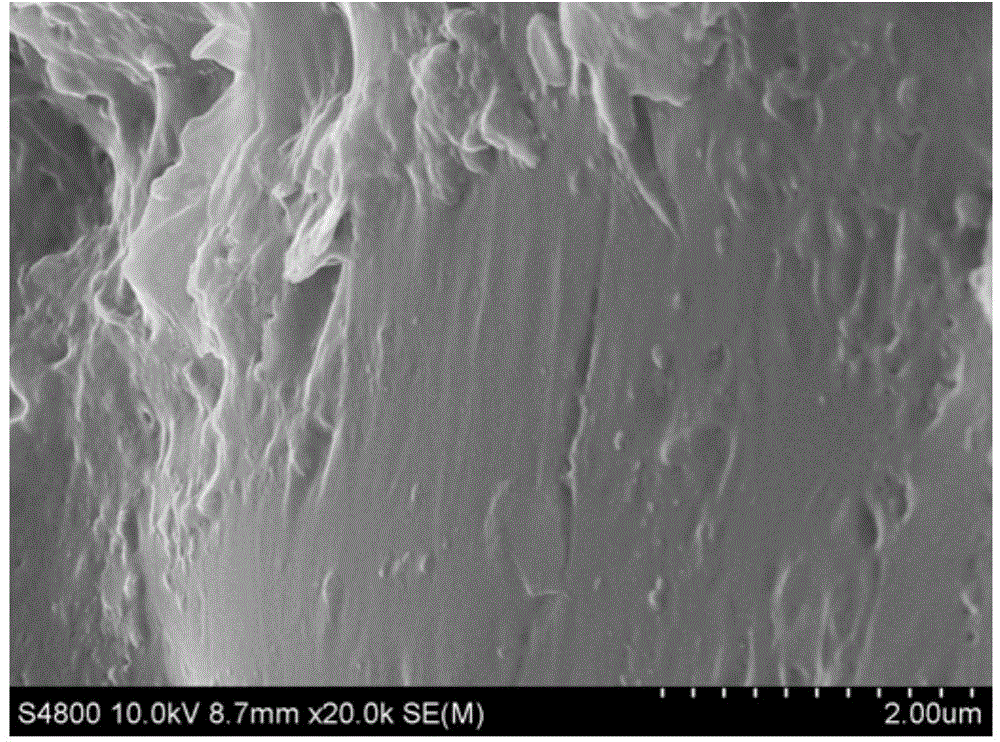

[0031] Put 3 pieces of 3cm×3cm polypropylene mesh into the tris (Tris) buffer solution with a concentration of 9mmol / L. The surface of the polypropylene material is smooth as observed by the electron microscope. The polypropylene mesh is woven from polypropylene. The medical lightweight patch has a pore size of 2mm, and the surface of the polypropylene material is smooth, and no dopamine and other substances are attached; then 0.9g of dopamine hydrochloride is added, and the final concentration of the prepared dopamine hydrochloride is 1.8g / L. The stirring reaction was carried out under the atmosphere, the rotation speed was 400 rpm, and the reaction was taken out after 24 hours. The resulting polypropylene mesh was rinsed with a large amount of deionized water until the solution was clear, and dried in a vacuum oven at 30°C to obtain a black polydopamine-coated anti-adhesion polypropylene mesh material for abdominal wall defect repair.

[0032] as attached Figure 7 Shown: 1...

Embodiment 2

[0036] Put 2 pieces of 2cm×3cm polypropylene mesh into 50ml buffer solution of Tris (Tris) with a concentration of 10mmol / L. The polypropylene mesh is a medical lightweight patch made of polypropylene weaving , the pore diameter is 2.5mm, then add 1g of dopamine hydrochloride, the final concentration of the prepared dopamine hydrochloride is 2g / L, carry out stirring reaction at 30°C, the rotation speed is 600rpm, take out after 48h of reaction. The resulting polypropylene mesh was rinsed with a large amount of deionized water until the solution was clear, and dried in a vacuum oven at 30° C. to obtain a dark black polydopamine-coated anti-blocking polypropylene mesh material.

[0037] The thickness of the polydopamine film was measured to be about 1.5 μm by electron microscope observation of the deep black polypropylene / polydopamine repair material.

Embodiment 3

[0039] Put 4 pieces of 2cm×2cm polypropylene mesh into 50ml buffer solution of Tris (Tris) with a concentration of 11mmol / L. The polypropylene mesh is a medical lightweight patch woven from polypropylene , the pore diameter is 3mm, then add 1.2g of dopamine hydrochloride, the final concentration of the prepared dopamine hydrochloride is 2.4g / L, carry out stirring reaction at 25°C, the rotation speed is 600rpm, take out after 36h of reaction. The resulting polypropylene mesh was rinsed with a large amount of deionized water until the solution was clear, and dried in a vacuum oven at 30° C. to obtain a light black polydopamine-coated anti-blocking polypropylene mesh material.

[0040] The thickness of polydopamine film is about 800nm observed by electron microscope on light black polypropylene / polydopamine repair material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com