Composition, black matrix and preparation method thereof, display devices

A display device and composition technology, which is applied to opto-mechanical equipment, photo-engraving process of pattern surface, optics, etc., can solve the problem of high post-baking temperature, low black matrix resistance, post-baking temperature that cannot be used in OLED display devices and Flexible display devices and other problems, to achieve the effect of complete polymerization, overcoming undercutting, and stable cured film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

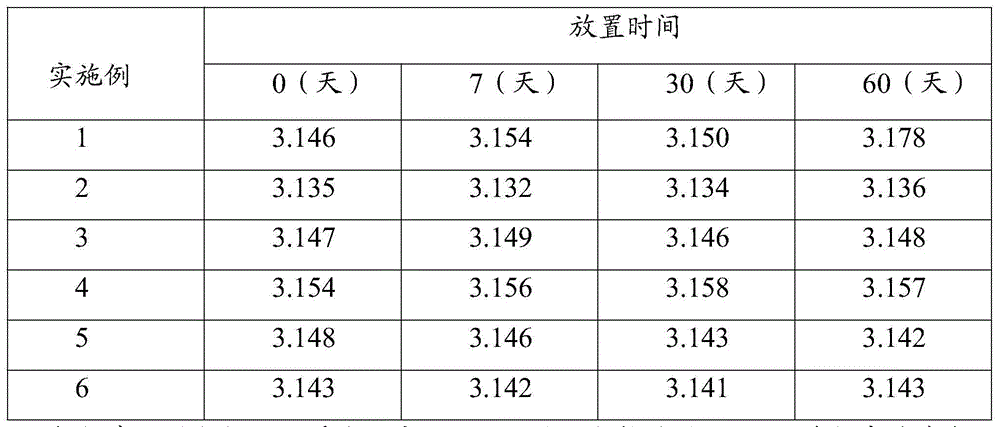

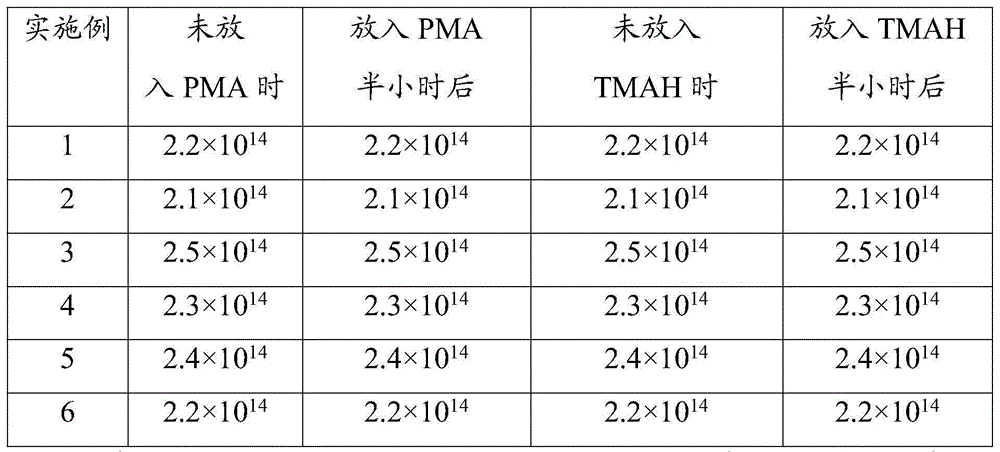

[0034] According to another aspect of the present invention, a method for preparing a black matrix is provided. The composition according to the present invention is used to prepare a black matrix, wherein the method includes: pre-baking operation: baking at 40°C to 65°C for 110 ~300 seconds; post-baking operation: bake at 80°C-180°C for 60-120 minutes.

[0035]According to the preparation method of the black matrix of the present invention, firstly, the evenly stirred black photoresist composition is uniformly coated on a clean glass substrate, and most of the solvent is removed in the pre-baking step, and the pre-baking temperature is reduced to 40° C. to 65° C., and further Preferably 45°C to 60°C, the baking time is 110 to 300 seconds, more preferably 180 to 250 seconds, the pre-baking temperature can be adjusted according to the decomposition temperature of the thermal initiator, generally 10°C to 10°C lower than the decomposition temperature of the initiator 80°C to pr...

Embodiment 1

[0046] The black photoresist composition according to the present invention comprises: 30 parts of monomer solids, 25 parts of resin solids, 20 parts of black pigment liquid solids, 6 parts of initiators and 5 parts of auxiliary agents; wherein, the initiators include thermal initiators And photoinitiator, the mass ratio of thermal initiator and photoinitiator is 1:10, and photoinitiator is 1-[4-(phenylthio) phenyl]-1,2-octanedione-2-(O- Benzoyl oxime), thermal initiator is azobisisobutyronitrile of azo initiator; resin is acrylate resin, molecular weight is 13000, 8000 or 9000, acid value is 120, 70 or 80; monomer is Dipentaerythritol hexaacrylate; the auxiliary agent is pentaerythritol tetra-3 mercaptoacrylate.

[0047] The composition was dissolved in propylene glycol methyl ether acetate, and evenly coated on a clean glass substrate, the pre-baking temperature was 40°C, and the baking time was 110 seconds; after the pre-baking step was completed, the glass substrate was co...

Embodiment 2

[0049] The black photoresist composition according to the present invention comprises: 35 parts of monomer solids, 35 parts of resin solids, 30 parts of black pigment liquid solids, 20 parts of initiators and 10 parts of auxiliary agents, wherein the initiators include thermal initiators And photoinitiator, the mass ratio of thermal initiator and photoinitiator is 3:1, and photoinitiator is 1-[9-ethyl-6-(2-methylbenzoyl)-9H-carbazol-3-yl ] ethyl ketone-1-(O-acetyl oxime), thermal initiator is diisopropyl peroxydicarbonate of organic peroxygen initiator; Resin is acrylic ester resin, and the molecular weight of acrylic resin is 13000,8000 or 9000, the acid value is 120, 70 or 80; the monomer is dipentaerythritol hexaacrylate; the auxiliary agent is pentaerythritol tetra-3 mercaptoacrylate;

[0050] Dissolve the above composition in propylene glycol methyl ether, and evenly coat it on a clean glass substrate. The pre-baking temperature is 65°C, and the baking time is 300 seconds...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com