Hydroxyapatite/polyamide composite biological material with nanofiber cellular structure on surface and preparing method thereof

A technology of composite biomaterials and hydroxyapatite, applied in medical science, prostheses, etc., can solve the problem of difficult balance between tough material and bone tissue, unfavorable cell or tissue adhesion growth, bone regeneration and bone fusion, etc. Problems, to achieve the effects that are conducive to the growth of adhesion, the transportation of nutrients and the elimination of metabolic waste, and the effects of vascularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this example, the preparation method of the hydroxyapatite / polyamide composite biomaterial with nanofiber porous structure on the surface is as follows:

[0032] (1) Dissolving 3 g of n-HA / PA composite material and 5 g of calcium chloride with an n-HA content of 50 wt % in 100 mL of absolute ethanol solution to form a spinning solution; the n-HA content of 20 wt % / PA66 composite material is made into a tubular matrix with a diameter of 10mm and a length of 30mm;

[0033] (2) With the tubular substrate prepared in step (1) as the closing screen of electrospinning, the spinning solution is spun on the substrate by electrospinning to get final product; in this step, the control spinning voltage is 15KV, and the nozzle reaches The distance of the receiving screen is 15cm, the spinning speed is 0.3mL / h, and the spinning time is 20min.

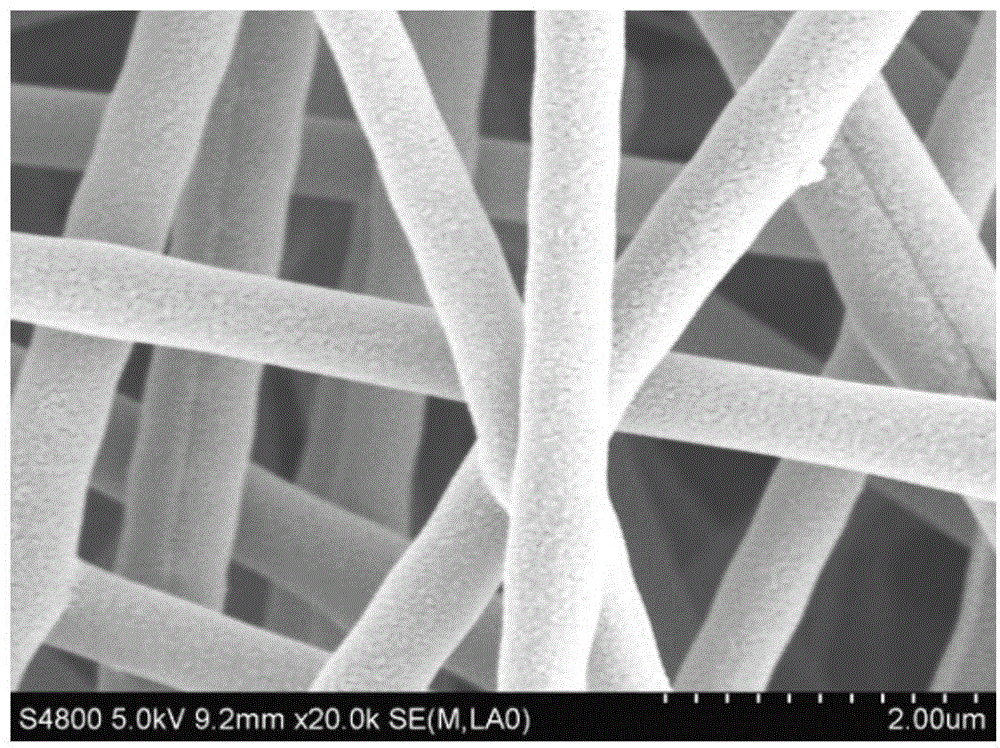

[0034] The scanning electron micrographs of the surface of the composite biomaterial prepared in this embodiment are as follows: figur...

Embodiment 2

[0036] In this example, the preparation method of the hydroxyapatite / polyamide composite biomaterial with nanofiber porous structure on the surface is as follows:

[0037] (1) Dissolving 0.1g of n-HA / PA composite material with n-HA content of 65wt%, calcium chloride 1g in 100mL absolute ethanol solution to form spinning solution; n-HA content of 25wt% n- HA / PA66 composite material is made into a tubular matrix with a diameter of 20mm and a length of 30mm;

[0038] (2) With the tubular substrate prepared in step (1) as the closing screen of electrospinning, the spinning solution is spun on the substrate by electrospinning to get final product; in this step, the control spinning voltage is 15KV, and the nozzle reaches The distance of the receiving screen is 5cm, the spinning speed is 0.5mL / h, and the spinning time is 15min.

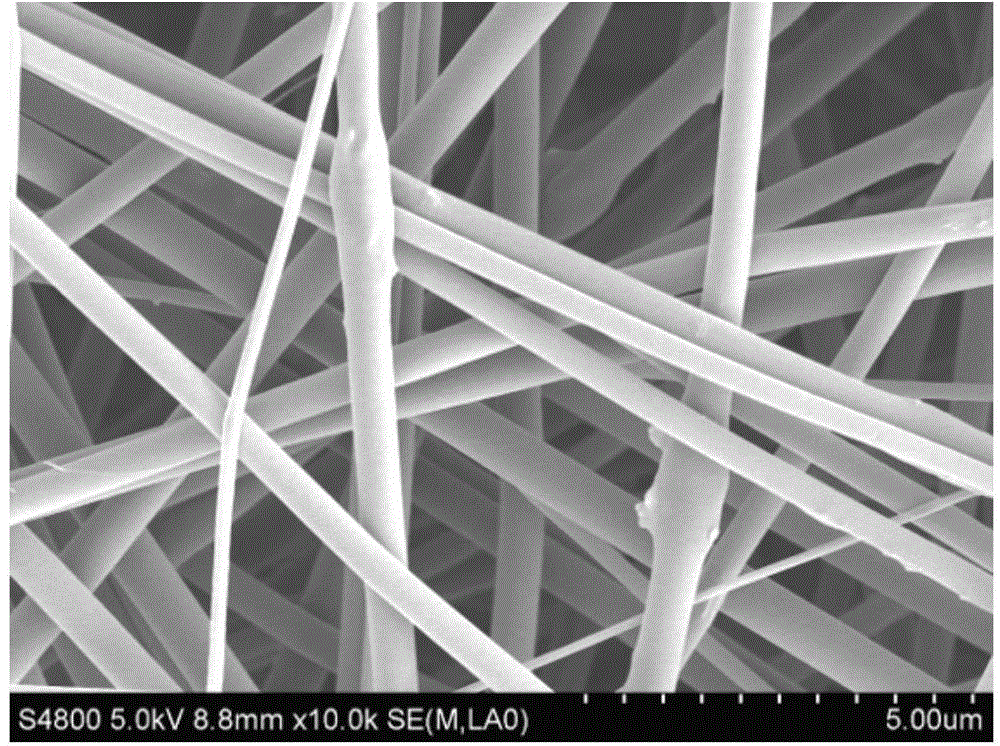

[0039] The scanning electron micrographs of the surface of the composite biomaterial prepared in this embodiment are as follows: figure 2 As shown, the ...

Embodiment 3

[0041]In this example, the preparation method of the hydroxyapatite / polyamide composite biomaterial with nanofiber porous structure on the surface is as follows:

[0042] (1) 5 g of n-HA / PA composite material with n-HA content of 65 wt %, calcium chloride 20 g are dissolved in 100 mL of absolute ethanol solution to form spinning solution; n-HA content of 25 wt % is n-HA / PA66 composite material is made into a tubular matrix with a diameter of 10mm and a length of 20mm;

[0043] (2) With the tubular substrate prepared in step (1) as the closing screen of electrospinning, the spinning solution is spun on the substrate by electrospinning to get final product; in this step, the control spinning voltage is 10KV, and the nozzle reaches The distance of the receiving screen is 30cm, the spinning speed is 0.7mL / h, and the spinning time is 30min.

[0044] The scanning electron micrographs of the surface of the composite biomaterial prepared in this embodiment are as follows: figure 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com