A kind of spray PVDF fluorocarbon self-cleaning varnish and preparation method thereof

A fluorocarbon self-cleaning type and varnish technology, which is applied in the direction of coating, etc., can solve the problems that the cleaning effect has not been studied and the cleaning effect is not maintained for a long time, and achieves a wide range of applicable temperatures, good adhesion, and reduced maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

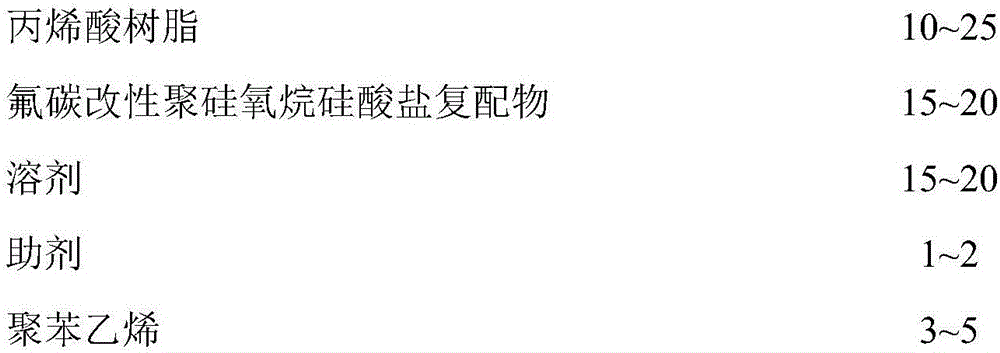

[0059] The sprayed PVDF fluorocarbon self-cleaning varnish provided in this embodiment is mainly composed of component A and component B, and component A is made of the following raw materials in proportion by mass:

[0060]

[0061] B component

[0062] Polyisocyanate curing agent 4.

[0063] PVDF fluorocarbon resin is polyvinylidene fluoride.

[0064] Acrylic resins are thermoplastic acrylic resins.

[0065] The solvent is toluene.

[0066] Fluorocarbon modified polysiloxane silicate compound is made of fluorocarbon modified polysiloxane, silicate, solvent and wetting and dispersing agent, fluorocarbon modified polysiloxane, silicate and The mass ratio of the three solvents is 2.5:6:1.5, and the amount of the wetting and dispersing agent accounts for 1.5% of the total mass of the fluorocarbon-modified polysiloxane, the silicate and the solvent.

[0067] Fluorocarbon modified polysiloxane is fluorine modified polysiloxane compound (model MCK-2130, Guangzhou Qiansong Po...

Embodiment 2

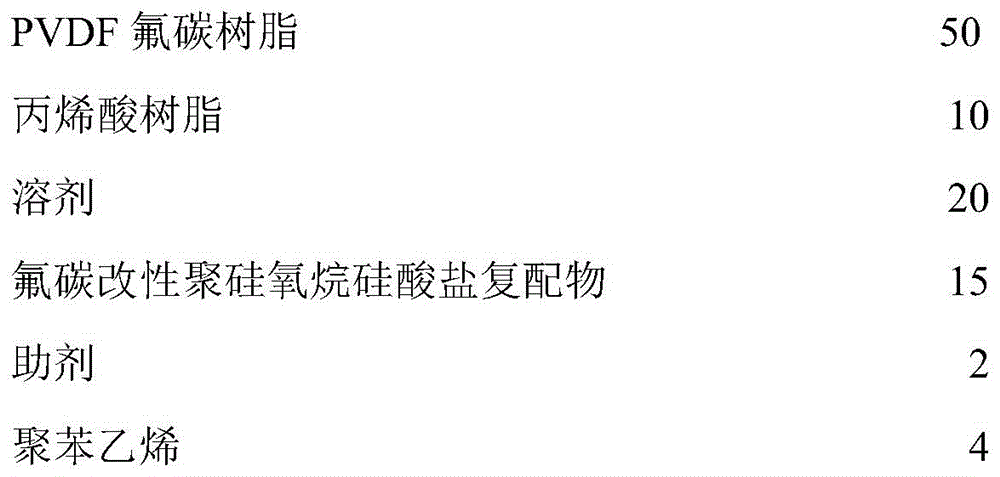

[0087] The sprayed PVDF fluorocarbon self-cleaning varnish provided in this embodiment is mainly composed of component A and component B, and component A is made of the following raw materials in proportion by mass:

[0088]

[0089] B component

[0090] Polyisocyanate curing agent 3.

[0091] The PVDF fluorocarbon resin is polyvinylidene fluoride.

[0092] Acrylic resins are thermosetting acrylic resins.

[0093] The solvent is the dibasic acid ester mixture DBE.

[0094] Fluorocarbon modified polysiloxane silicate compound is made of fluorocarbon modified polysiloxane, silicate, solvent and wetting and dispersing agent, fluorocarbon modified polysiloxane, silicate and The mass ratio of the three solvents is 1:7:1, and the amount of the wetting and dispersing agent accounts for 1% of the total mass of the fluorocarbon-modified polysiloxane, the silicate and the solvent.

[0095] Fluorocarbon modified polysiloxane is fluorine modified polysiloxane compound (model MCK-21...

Embodiment 3

[0116] The sprayed PVDF fluorocarbon self-cleaning varnish provided in this embodiment is mainly composed of component A and component B, and component A is made of the following raw materials in proportion by mass:

[0117]

[0118] B component

[0119] Polyisocyanate curing agent 2.

[0120] Among them, the PVDF fluorocarbon resin is polyvinylidene fluoride multi-polymer.

[0121] Acrylic resin is a mixture of thermoplastic acrylic resin and thermosetting acrylic resin, the mass ratio of the two is 1:1.

[0122] The solvent is a mixture of isophorone and butanone, and the volume ratio of the two is 1:1.

[0123] Fluorocarbon modified polysiloxane silicate compound is made of fluorocarbon modified polysiloxane, silicate, solvent and wetting and dispersing agent, fluorocarbon modified polysiloxane, silicate and The mass ratio of the three solvents is 1.5:6.5:1.5, and the amount of the wetting and dispersing agent accounts for 2% of the total mass of the fluorocarbon-modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com