Preparation of pH- and glucose-sensitive mesoporous silica@polymer drug carrier

A mesoporous silica and dual-sensitivity technology, applied in the field of nanomaterials, achieves good biocompatibility and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

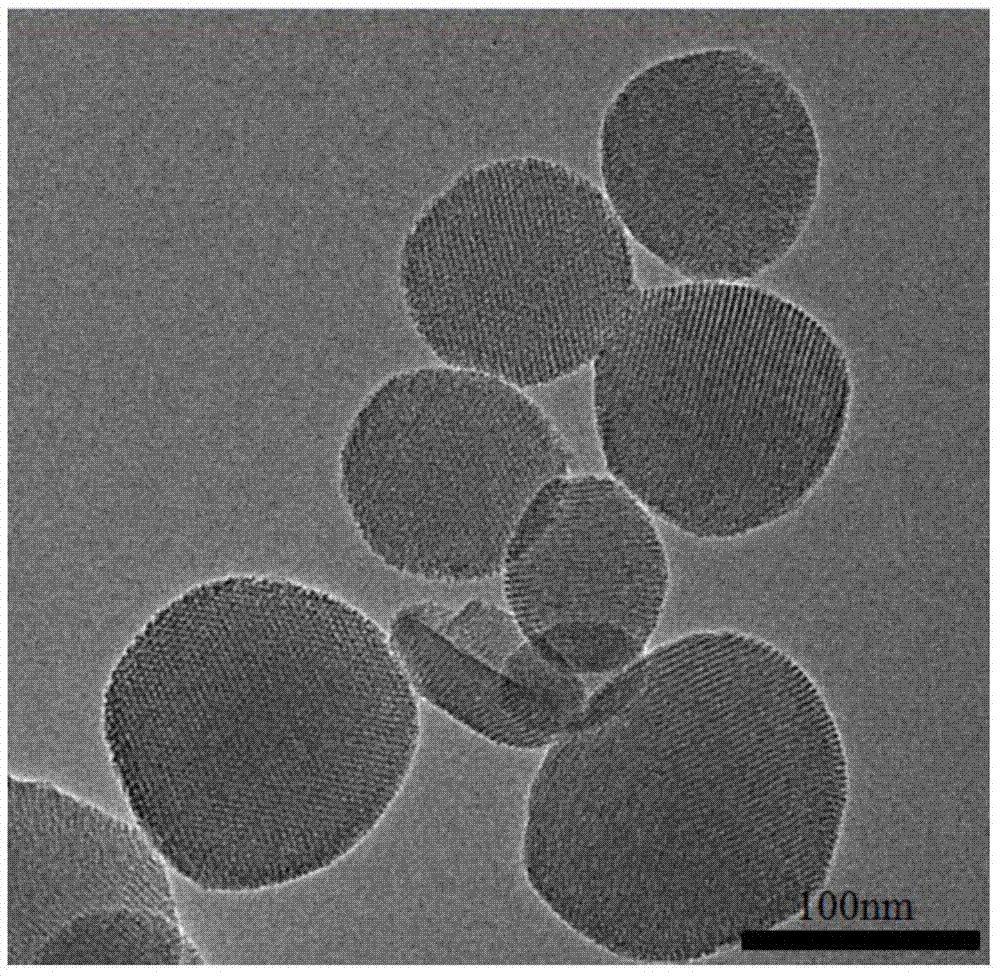

[0035] (1) Preparation of catechol-modified mesoporous silica

[0036] a. Dissolve 0.3g CTAB, 0.3mL ammonia water and 0.2mLTEOS in 50mL distilled water, place in a 100mL single-necked round bottom flask, and stir in an oil bath at 50°C for 2h. At the end of the reaction, the white precipitate was collected by centrifugation, washed with distilled water and ethanol for 3 to 5 times, and dried to obtain a white powder.

[0037] b. Disperse the white powder obtained in step a in 0.6 g / mL ammonium nitrate ethanol solution, heat to reflux for 12 hours, centrifuge to collect the white precipitate after the reaction, wash with ethanol for 3 to 5 times, and dry to obtain a white powder.

[0038] c. Disperse the white powder obtained in step b in ethanol, add 0.2mL 3-aminopropyltriethoxysilane, heat and reflux at 80°C for 24h, centrifuge to collect the white precipitate after the reaction, wash with ethanol for 3 to 5 times , dried to obtain a white powder.

[0039] d. Disperse the w...

Embodiment 2

[0049] (1) Preparation of catechol-modified mesoporous silica

[0050] a. Dissolve 0.5g CTAB, 0.5mL ammonia water and 0.2mLTEOS in 50mL distilled water, place in a 100mL single-necked round bottom flask, and stir in an oil bath at 50°C for 4h. At the end of the reaction, the white precipitate was collected by centrifugation, washed with distilled water and ethanol for 3 to 5 times, and dried to obtain a white powder.

[0051] b. Disperse the white powder obtained in step a in 0.6 g / mL ammonium nitrate ethanol solution, heat to reflux for 12 hours, centrifuge to collect the white precipitate after the reaction, wash with ethanol for 3 to 5 times, and dry to obtain a white powder.

[0052] c. Disperse the white powder prepared in step b in ethanol, add 0.5mL 3-aminopropyltriethoxysilane, heat and reflux at 80°C for 24h, centrifuge to collect the white precipitate after the reaction, wash with ethanol for 3 to 5 times , dried to obtain a white powder.

[0053] d. Disperse the w...

Embodiment 3

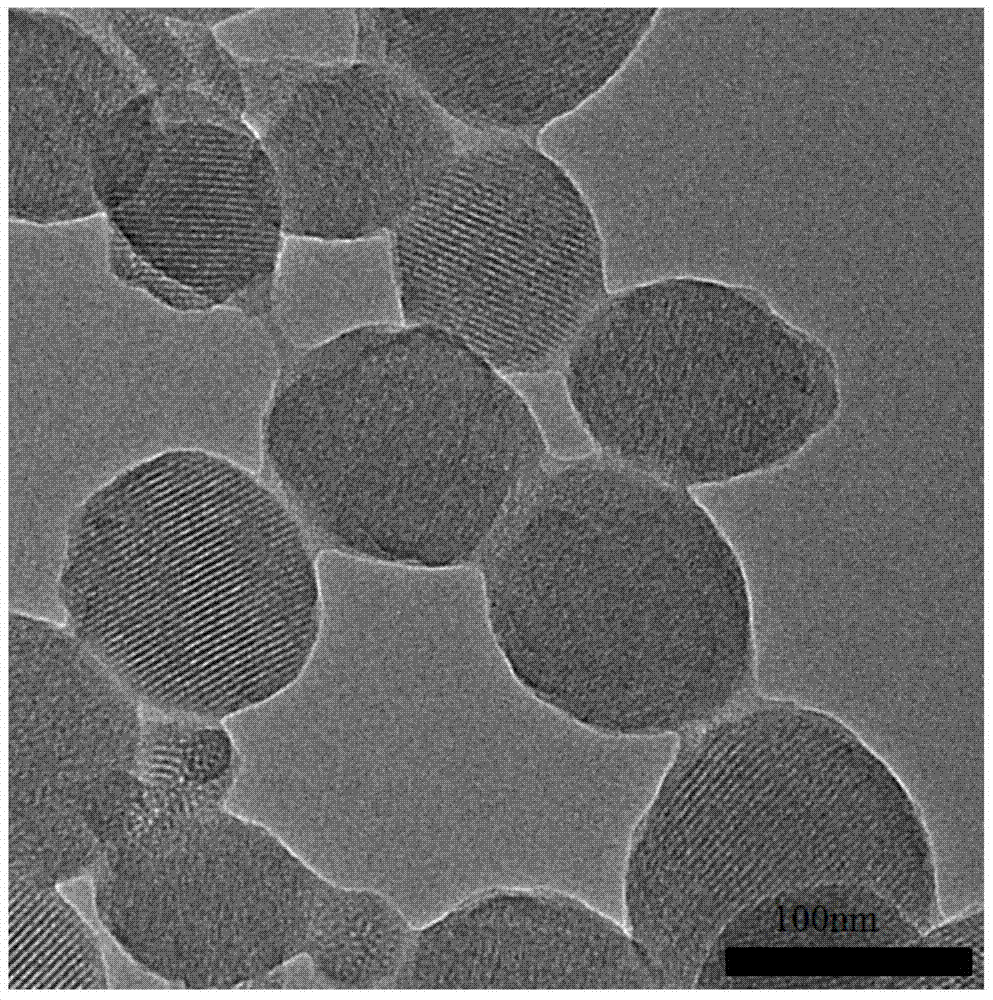

[0062] (1) Preparation of catechol-modified mesoporous silica

[0063] a. Dissolve 0.8g CTAB, 0.8mL ammonia water and 0.4mLTEOS in 60mL distilled water, place in a 100mL single-necked round bottom flask, and stir in an oil bath at 50°C for 4h. At the end of the reaction, the white precipitate was collected by centrifugation, washed with distilled water and ethanol for 3 to 5 times, and dried to obtain a white powder.

[0064] b. Disperse the white powder obtained in step a in 0.6 g / mL ammonium nitrate ethanol solution, heat to reflux for 12 hours, centrifuge to collect the white precipitate after the reaction, wash with ethanol for 3 to 5 times, and dry to obtain a white powder.

[0065] c. Disperse the white powder prepared in step b in ethanol, add 1mL of 3-aminopropyltriethoxysilane, heat and reflux at 80°C for 24h, centrifuge to collect the white precipitate after the reaction, wash with ethanol for 3 to 5 times, Drying gave a white powder.

[0066] d. Disperse the white...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com