A kind of modification method of hplc chromatographic column filler

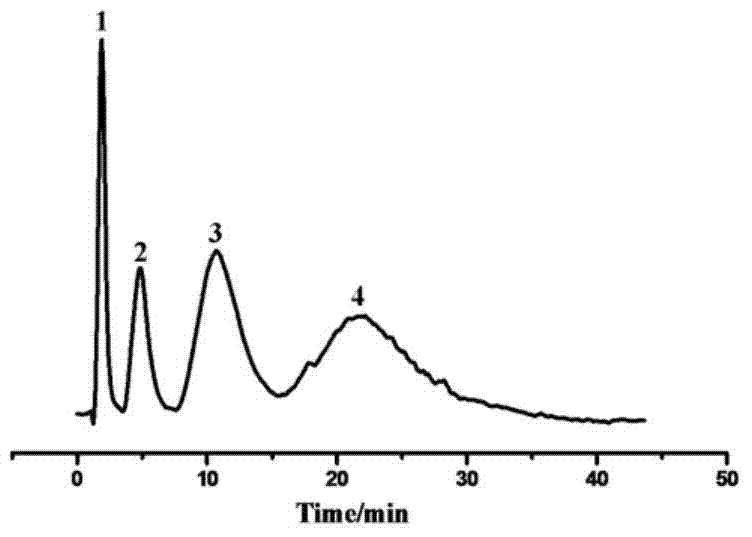

A chromatographic column packing and modification technology, which is applied in the field of modifying the surface of silica microspheres by using photosensitive polymer diazo resin, can solve the problems of unfriendly environment, complicated preparation method and time-consuming, etc. Easy to obtain, good separation effect, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The modification method of the HPLC chromatographic column filler silica microsphere of the present embodiment, comprises the following steps:

[0038] S1. Activation treatment of silica microspheres:

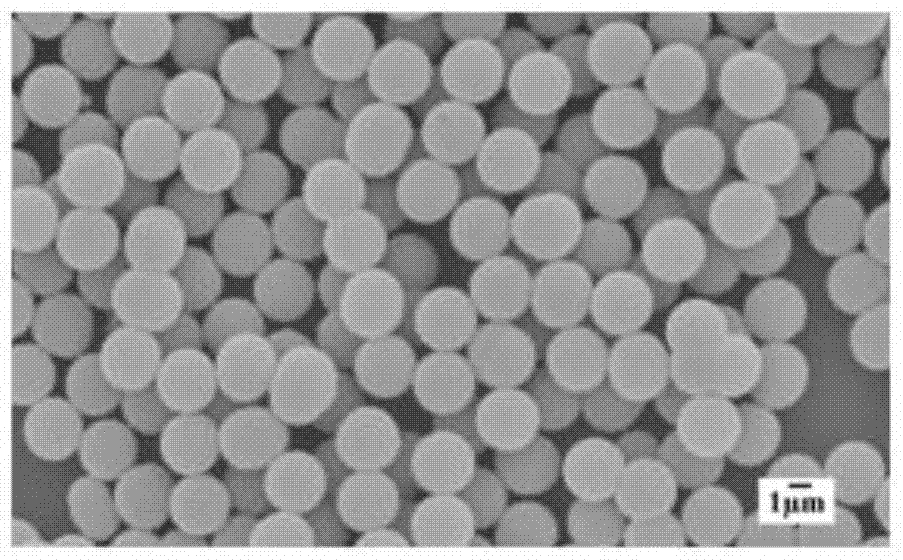

[0039] Disperse 0.5 g of monodisperse silica microspheres with a particle size of 2.5 μm uniformly in a strong alkali sodium hydroxide with a concentration of 0.1 mol / L for 30 minutes, centrifuge and wash the silica microspheres to neutrality;

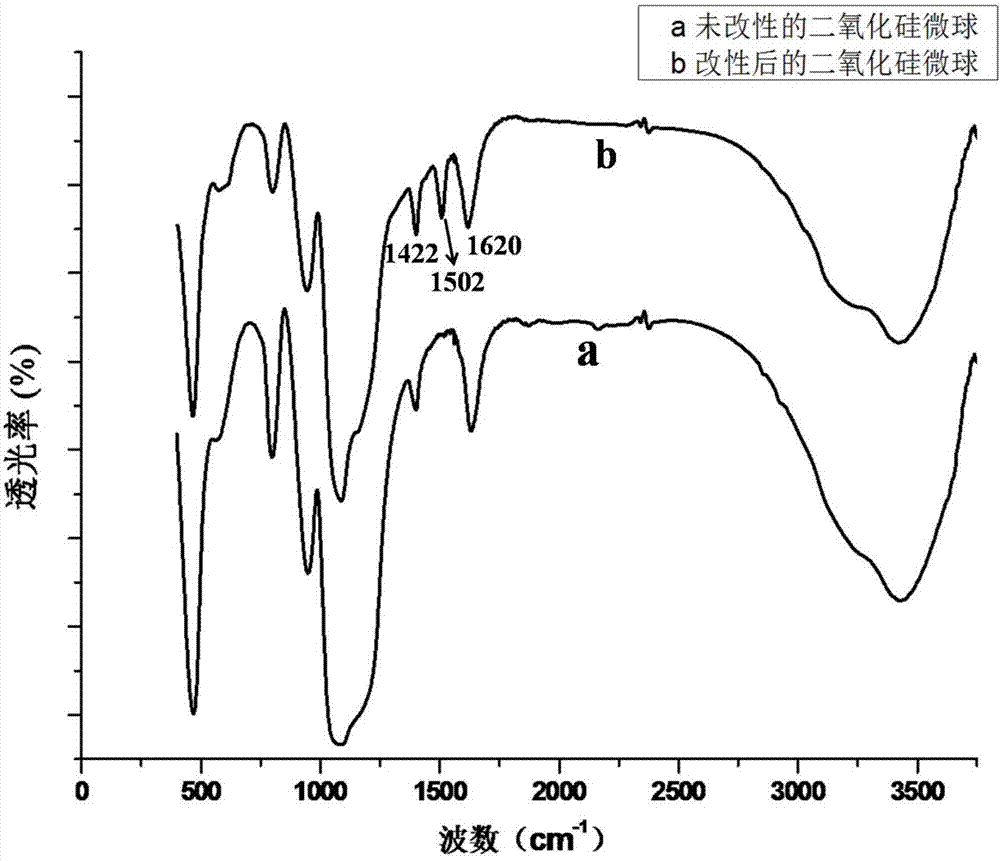

[0040] S2, modifying the silica microspheres after the activation treatment:

[0041] The activated silica microspheres were placed in an aqueous solution of diazo resin with a concentration of 4 mg / mL, and reacted with magnetic stirring at room temperature for 2 hours in a light-proof environment, and then centrifuged, and the product was washed 3 times with deionized water, The obtained product was treated overnight in a vacuum drying oven, and the dried silica microspheres were exposed to ultraviolet light for 15 minutes to o...

Embodiment 2

[0045] The modification method of the HPLC chromatographic column filler silica microsphere of the present embodiment, comprises the following steps:

[0046] S1. Activation treatment of silica microspheres:

[0047]Disperse 0.5 g of monodisperse silica microspheres with a particle size of 1 μm uniformly in a strong alkali potassium hydroxide solution with a concentration of 0.08 mol / L for 45 minutes, centrifuge and wash the silica microspheres to neutrality;

[0048] S2, modifying the silica microspheres after the activation treatment:

[0049] The activated silica microspheres were placed in an aqueous solution of diazo resin with a concentration of 3 mg / mL, and reacted with magnetic stirring at room temperature for 3 hours in a light-proof environment, and then the product was washed twice with deionized water after centrifugation. The obtained product was treated overnight in a vacuum drying oven, and the dried silica microspheres were exposed to ultraviolet light for 20 ...

Embodiment 3

[0052] The modification method of the HPLC chromatographic column filler silica microsphere of the present embodiment, comprises the following steps:

[0053] S1. Activation treatment of silica microspheres:

[0054] Disperse 0.5 g of monodisperse silica microspheres with a particle size of 5 μm uniformly in a strong hydrochloric acid solution with a concentration of 0.15 mol / L for 20 minutes, centrifuge and wash the silica microspheres to neutrality;

[0055] S2, modifying the silica microspheres after the activation treatment:

[0056] The activated silica microspheres were placed in an aqueous solution of diazo resin with a concentration of 5 mg / mL, and reacted with magnetic stirring at room temperature for 4 hours in a light-proof environment, and then centrifuged, and the product was washed 3 times with deionized water, The obtained product was placed in a vacuum drying oven for overnight treatment, and the dried silica microspheres were exposed to ultraviolet light for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com