a ta 3 no 5 /cds heterojunction fiber photocatalyst and preparation method thereof

A photocatalyst and heterojunction technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the serious recombination of photogenerated electrons and holes, unsatisfactory photocatalytic activity, and narrow band gap and other problems, to achieve the effects of easy recycling, improved visible light photocatalytic activity, and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

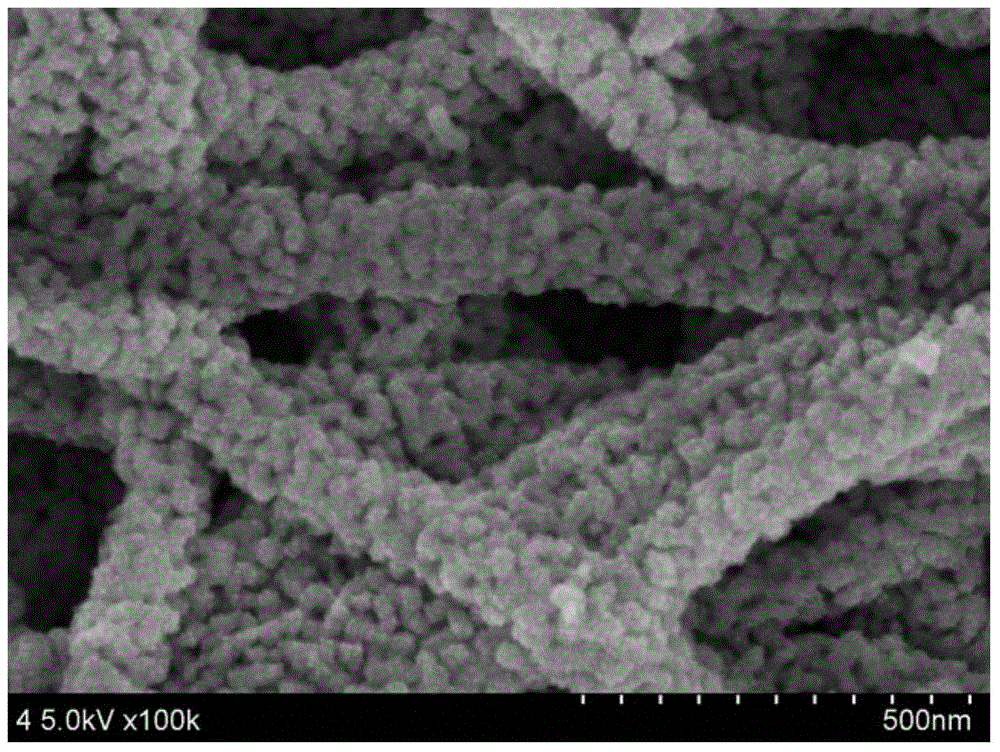

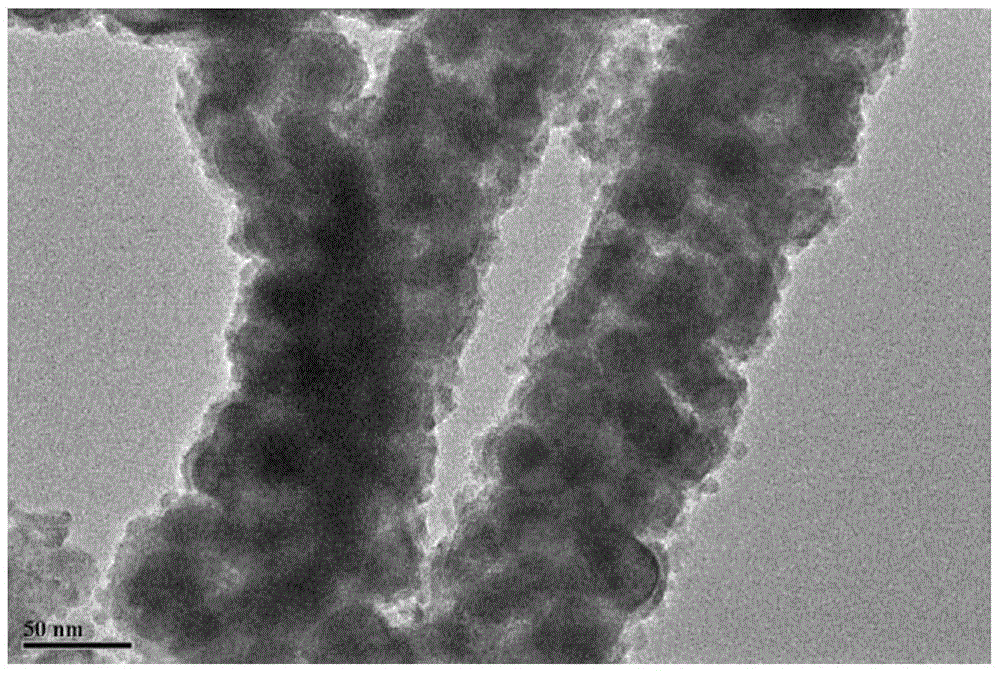

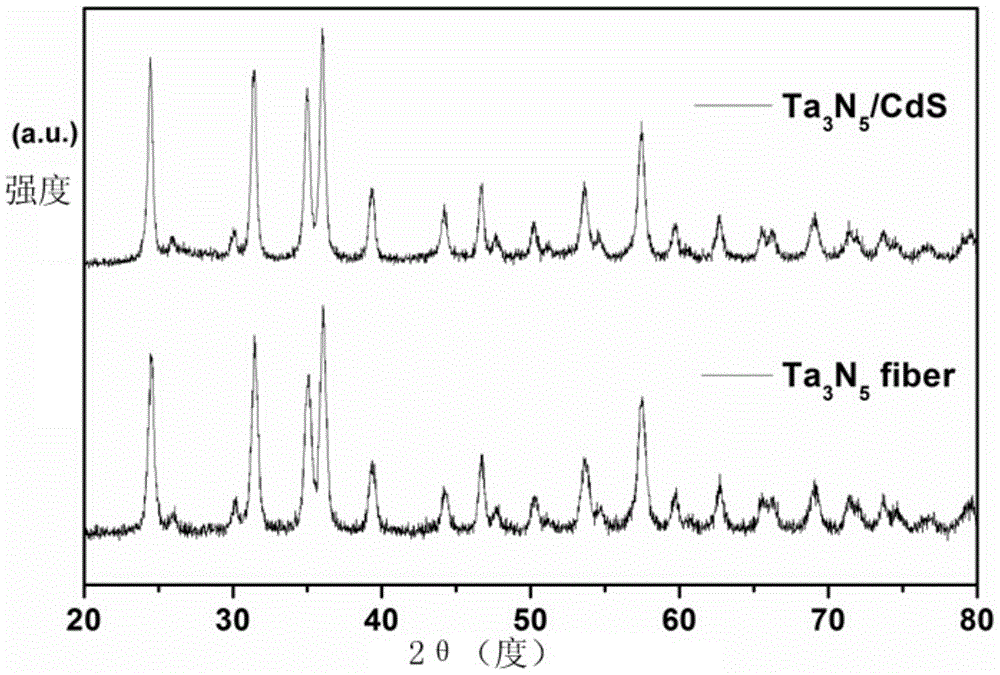

[0037] A Ta 3 N 5 The preparation method of / CdS heterojunction fiber photocatalyst comprises the following steps:

[0038] Step 1, prepare Ta 3 N 5 Spinning liquid: add soluble tantalum salt into the polymer solution and stir for 2-12 hours to obtain Ta 3 N 5 spinning solution.

[0039] The polymer solution in the polymer solution is made by mixing polyvinylpyrrolidone (PVP), absolute ethanol, N,N-dimethylformamide, and acetic acid, wherein the absolute ethanol, N,N-dimethylformamide The volume ratio to acetic acid is (3-4): 1: 1 (for example, it can also be any ratio in 3.2: 1: 1, 3.5: 1: 1, 3.8: 1: 1, 4: 1: 1 , preferably 3:1:1), the molecular weight of the PVP is 1,300,000;

[0040] The Ta 3 N 5 In the spinning solution, the mass percentage concentration of the PVP is 5-10wt% (for example, it can be any value in 5wt%, 6wt%, 7wt%, 8wt%, 10wt%, etc. or any range between the two, Preferably 9wt%), the mass percentage concentration of this soluble tantalum salt is 5~...

Embodiment 1

[0054] (1) Preparation of Ta 3 N 5 Spinning solution: add tantalum ethoxide to the polymer solution, and magnetically stir for 8 hours to obtain Ta 3 N 5 spinning solution.

[0055] The polymer solution is made by mixing PVP with a molecular weight of 1,300,000, absolute ethanol, N,N-dimethylformamide, and acetic acid; wherein, the volume of the absolute ethanol, N,N-dimethylformamide, and acetic acid The ratio is 3:1:1;

[0056] The Ta 3 N 5 In the spinning solution, the mass percentage concentration of the PVP is 9 wt%, and the mass percentage concentration of the tantalum ethoxide is 11 wt%.

[0057] (2) Preparation of Ta 2 o 5 Fiber: the Ta 3 N 5 The spinning solution is subjected to electrospinning treatment, the conditions are: DC voltage 15kV, working distance 10cm, propeller speed 0.5mL / h, syringe needle inner diameter 2-10mm; composite fiber is obtained;

[0058] Then the composite fiber was calcined at 600°C for 6h to obtain Ta 2 o 5 fiber.

[0059] (3)...

Embodiment 2

[0065] (1) Preparation of Ta 3 N 5 Spinning solution: add tantalum ethoxide to the polymer solution, and magnetically stir for 8 hours to obtain Ta 3 N 5 spinning solution.

[0066] The polymer solution is made by mixing PVP with a molecular weight of 1,300,000, absolute ethanol, N,N-dimethylformamide, and acetic acid; wherein, the volume of the absolute ethanol, N,N-dimethylformamide, and acetic acid The ratio is 3:1:1;

[0067] The Ta 3 N 5 In the spinning solution, the mass percentage concentration of the PVP is 9 wt%, and the mass percentage concentration of the tantalum ethoxide is 11 wt%.

[0068] (2) Preparation of Ta2O5 fiber: the Ta2O5 3 N 5 The spinning solution is subjected to electrospinning treatment, the conditions are: DC voltage 15kV, working distance 10cm, propeller speed 0.5mL / h, syringe needle inner diameter 2-10mm; composite fiber is obtained;

[0069] Then the composite fiber was calcined at 600° C. for 6 hours to obtain Ta2O5 fiber.

[0070] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com