Antistatic PP (polypropylene) plastic

An antistatic and PP technology, applied in the field of PP plastics, can solve the problems of unsatisfactory antistatic effect of PP plastics, and achieve the effects of not easy to absorb dust, high impact strength, and excellent antistatic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0023] Each raw material was weighed according to the data corresponding to Examples 1-4 in Table 1.

[0024] In the high-speed mixer, control the speed of the high-speed mixer at 350 rpm at room temperature, mix for 5 minutes, take it out and transfer it to a twin-screw extruder, extrude and granulate at a temperature of 210 ° C, and control the speed of the screw machine at 400 revolutions per minute to obtain the antistatic PP plastic.

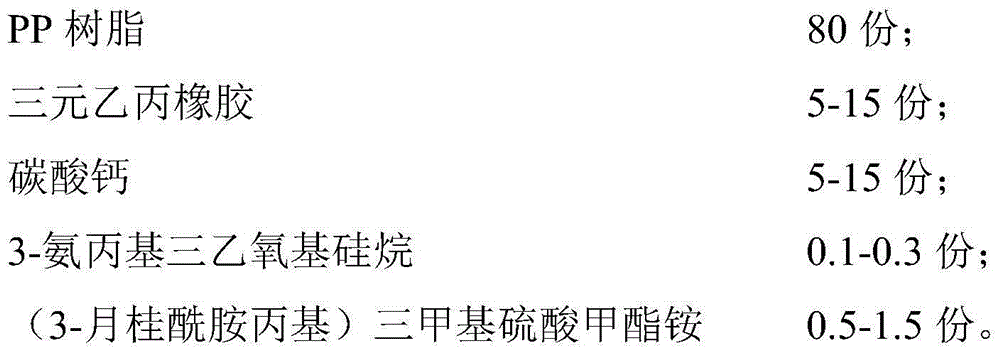

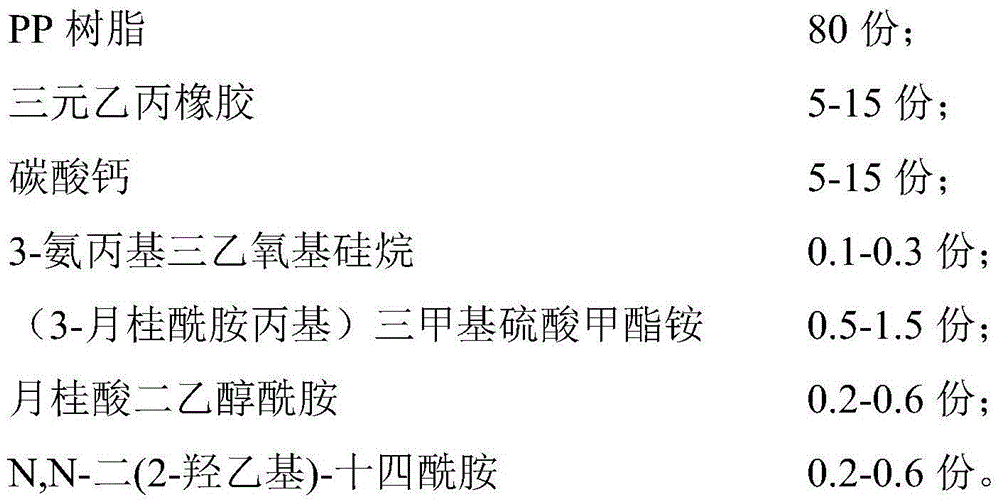

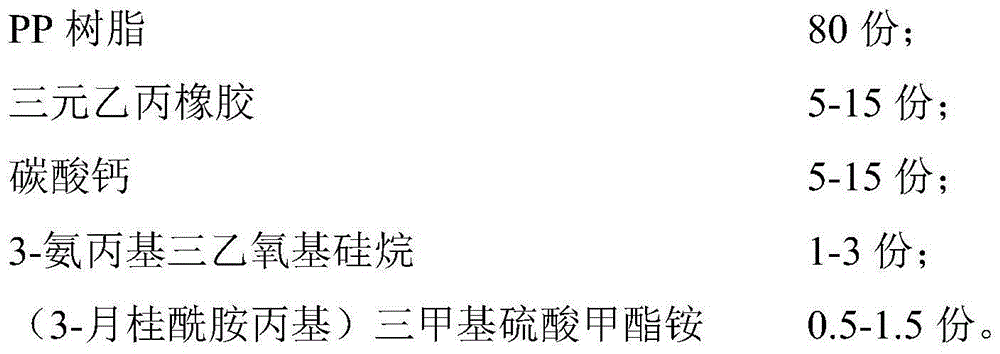

[0025] Table 1: Antistatic PP plastic formula table (unit: kg)

[0026] raw material

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com