Aluminum tantalum rotating target material, and method used for preparing aluminum tantalum rotating target material via controlled atmosphere cold spraying

A rotating target and cold spraying technology, applied in metal material coating process, coating, melting spraying and other directions, can solve the problems of target arc discharge, reduce film quality, increase coating cost, etc., and achieve dense coating structure, The target composition is uniform and the effect of avoiding segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Use ultrasonic cleaning to treat the stainless steel substrate for 30 minutes, then dry the cleaned substrate, and finally perform sandblasting on the substrate, using steel grit with a particle size of 18 mesh.

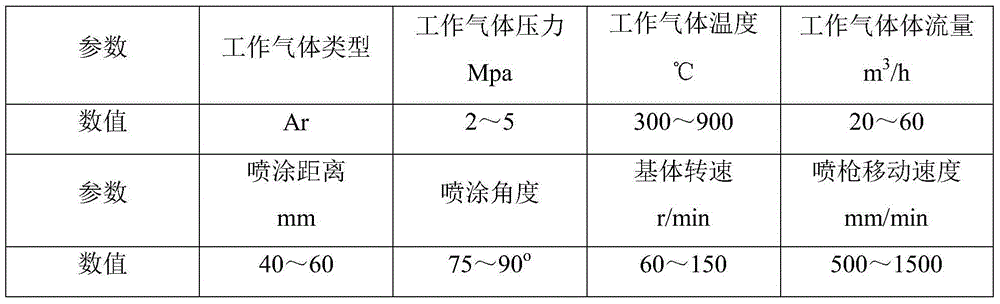

[0031] (2) In an argon protective atmosphere, use the plasma spraying method to spray nickel-aluminum powder to prepare a nickel-aluminum alloy transition layer with a thickness of 0.15mm. The specific parameters are shown in Table 1.1.

[0032] Table 1.1 Controlled atmosphere plasma spraying nickel aluminum powder parameters

[0033]

[0034] (3) The purity of the aluminum-tantalum powder is not lower than 99.99%. The powder is ball-milled for 5 hours, and sieved to obtain a powder with a particle size of 150-1000 mesh.

[0035] (4) The controllable atmosphere cold spraying chamber is evacuated first and then argon is introduced into the circulating protective gas. The argon flow rate is 1200SCCH, the substrate rotates around the central axis at a spee...

Embodiment 2

[0039] (1) Use ultrasonic cleaning to treat the stainless steel substrate for 30 minutes, then dry the cleaned substrate, and finally perform sandblasting on the substrate, using steel grit with a particle size of 18 mesh.

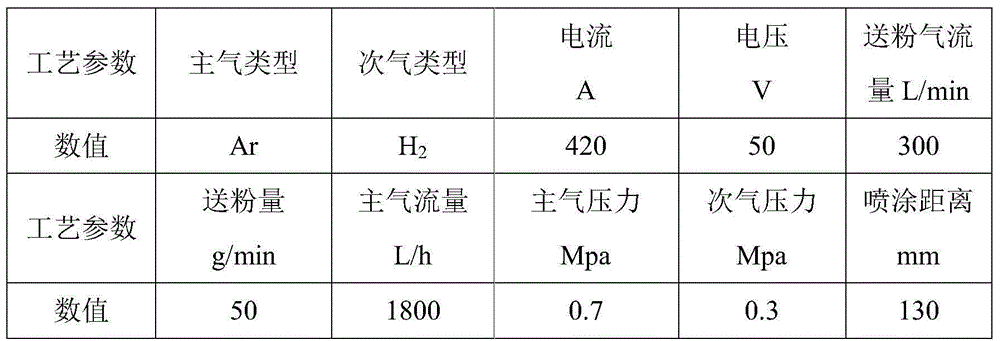

[0040] (2) In an argon protective atmosphere, nickel-aluminum powder was sprayed by a plasma spraying method to prepare a nickel-aluminum alloy transition layer with a thickness of 0.2 mm. The specific parameters are shown in Table 2.1.

[0041] Table 2.1 Controlled Atmosphere Plasma Spraying Nickel Aluminum Powder Parameters

[0042]

[0043] (3) The aluminum tantalum powder is not less than 99.99%, and the powder is ball milled for 5 hours, and sieved to obtain a powder with a particle size of 150-1000 mesh.

[0044] (4) Vacuumize the spraying chamber first and then pass in the circulating protection gas argon, the argon flow rate is 1200SCCH, the substrate rotates around the central axis at a speed of 100r / min, and the moving speed of the spray gun ...

Embodiment 3

[0048] (1) Use ultrasonic cleaning to treat the stainless steel substrate for 30 minutes, then dry the cleaned substrate, and finally perform sandblasting on the substrate, using steel grit with a particle size of 18 mesh.

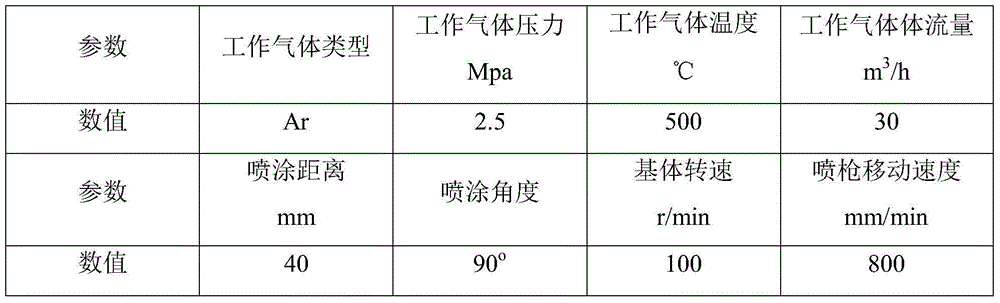

[0049] (2) In an argon protective atmosphere, nickel-aluminum powder was sprayed by a plasma spraying method to prepare a nickel-aluminum alloy transition layer with a thickness of 0.2 mm. The specific parameters are shown in Table 3.1.

[0050] Table 3.1 Controlled Atmosphere Plasma Spraying Nickel Aluminum Powder Parameters

[0051]

[0052] (3) The aluminum tantalum powder is not less than 99.99%, and the powder is ball milled for 5 hours, and sieved to obtain a powder with a particle size of 150-1000 mesh.

[0053] (4) Vacuum the spraying chamber first and then pass it into the circulating protection gas argon. The argon flow rate is 1200SCCH, the substrate rotates around the central axis at a speed of 100r / min, and the moving speed of the spray gu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com