Antimicrobial and antiviral composition, and method of producing the same

An antimicrobial and composition technology, applied in botany equipment and methods, biocides, animal repellants, etc., can solve the problem of reducing antimicrobial and antiviral performance, not disclosing methods for inhibiting copper oxide oxidation, easy oxidation, etc. problem, to achieve excellent antimicrobial and antiviral effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

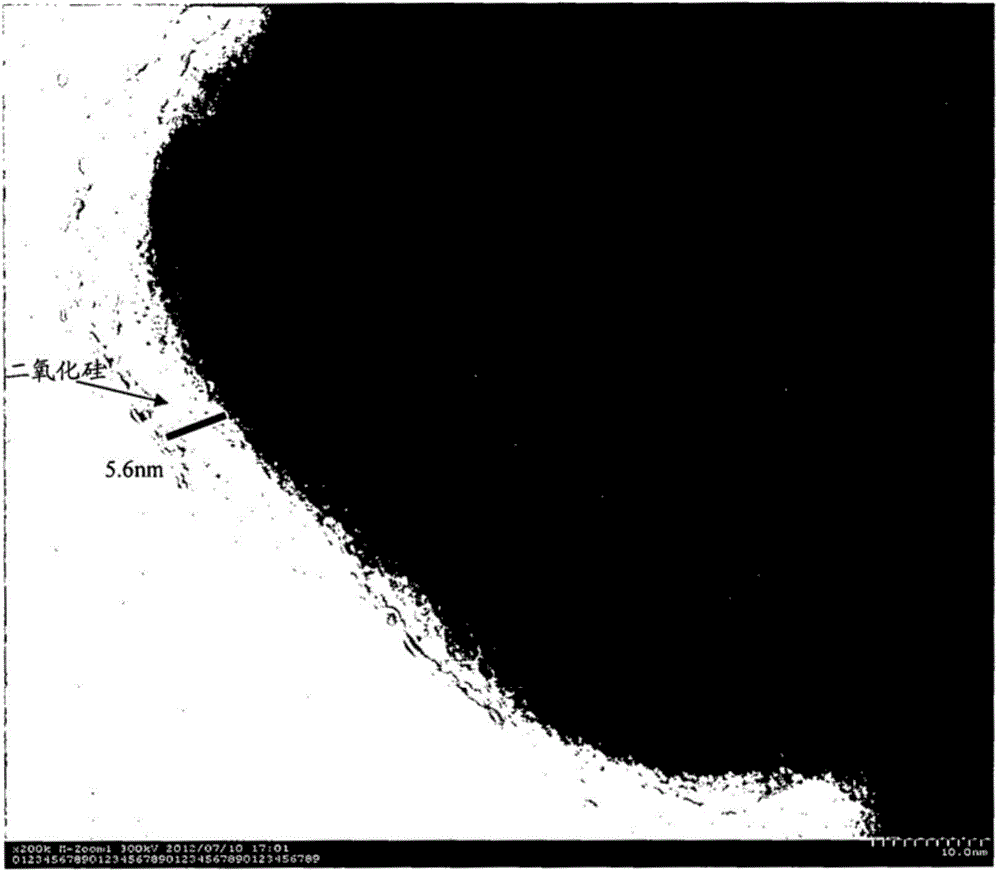

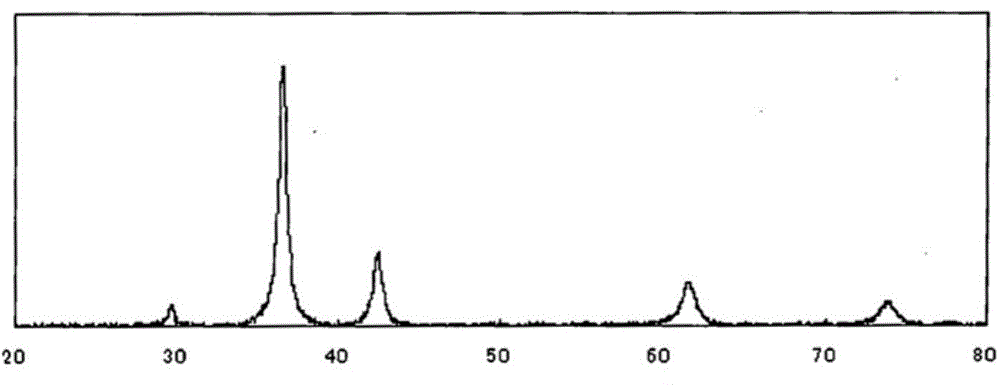

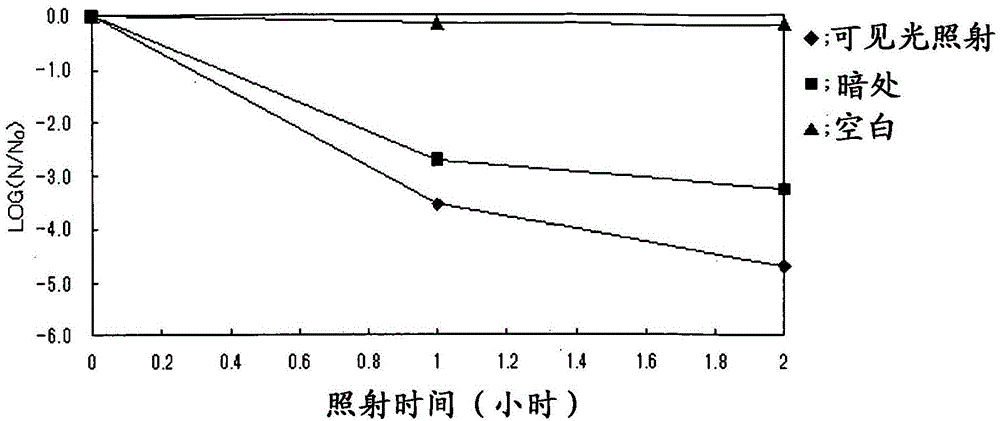

[0156] Heat 3000mL of distilled water to 50°C, then add 149.8g of copper sulfate (II) pentahydrate, while stirring until completely dissolved. Then, 200 g of 1.5 mol / L glucose aqueous solution was added, and then 720 g of 2 mol / L sodium hydroxide aqueous solution and 120 mL of 2 mol / L hydrazine hydrate aqueous solution were simultaneously added. After the mixture was vigorously stirred for 1 minute, the stirred mixture was filtered with a 0.3 μm membrane filter, then the filtered material was washed with 3000 mL of distilled water, and the solid content was collected. After drying at 60° C. for 3 hours, the solid content was pulverized with an agate mortar to obtain cuprous oxide particles. According to the nitrogen adsorption method, the BET specific surface area of the obtained cuprous oxide particles is 29.20m 2 / g. Suspension 1 was obtained by dispersing 5 g of the obtained cuprous oxide particles in 60 mL of ethanol solvent. 1.827 g of TEOS with a purity of 95% was a...

Embodiment 2

[0159] Cuprous oxide particles were prepared in the same manner as in Example 1. 5 g of the obtained cuprous oxide particles were dispersed in 60 mL of ethanol solvent to obtain Suspension 1. 2.742 g of TEOS with a purity of 95% was added to 20 mL of ethanol to obtain a solution 2 (which is equivalent to a total of 15 parts by mass of silica added based on 100 parts by mass of cuprous oxide particles). Solution 2 was mixed with suspension 1, and 10 mL of pure water was added to the mixture. Then, an antimicrobial and antiviral material (silica-coated cuprous oxide particles) B was obtained in the same manner as in Example 1. The mass and BET specific surface area of the silica coating layer in the obtained silica-coated cuprous oxide particles are shown in Table 1.

Embodiment 3

[0161] Cuprous oxide particles were prepared in the same manner as in Example 1. 5 g of the obtained cuprous oxide particles were dispersed in 60 mL of ethanol solvent to obtain Suspension 1. 3.654 g of TEOS with a purity of 95% was added to 20 mL of ethanol to obtain a solution 2 (which is equivalent to a total of 20 parts by mass of silica added based on 100 parts by mass of cuprous oxide particles). Solution 2 was mixed with suspension 1, and 10 mL of pure water was added to the mixture. Then, an antimicrobial and antiviral material (silica-coated cuprous oxide particles) C was obtained in the same manner as in Example 1. The mass and BET specific surface area of the silica coating layer in the obtained silica-coated cuprous oxide particles are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com