Guanidyl-functionalized graphene oxide/polysulfone ultrafiltration membrane and preparation method thereof

A polysulfone ultrafiltration membrane and amino functionalization technology are applied in the field of guanidine functionalized graphene oxide/polysulfone ultrafiltration membrane and its preparation, which can solve the problems of impairing membrane performance, increasing operating costs and the like, and improving separation performance. , and the effect of anti-pollution improvement and pure water flux improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

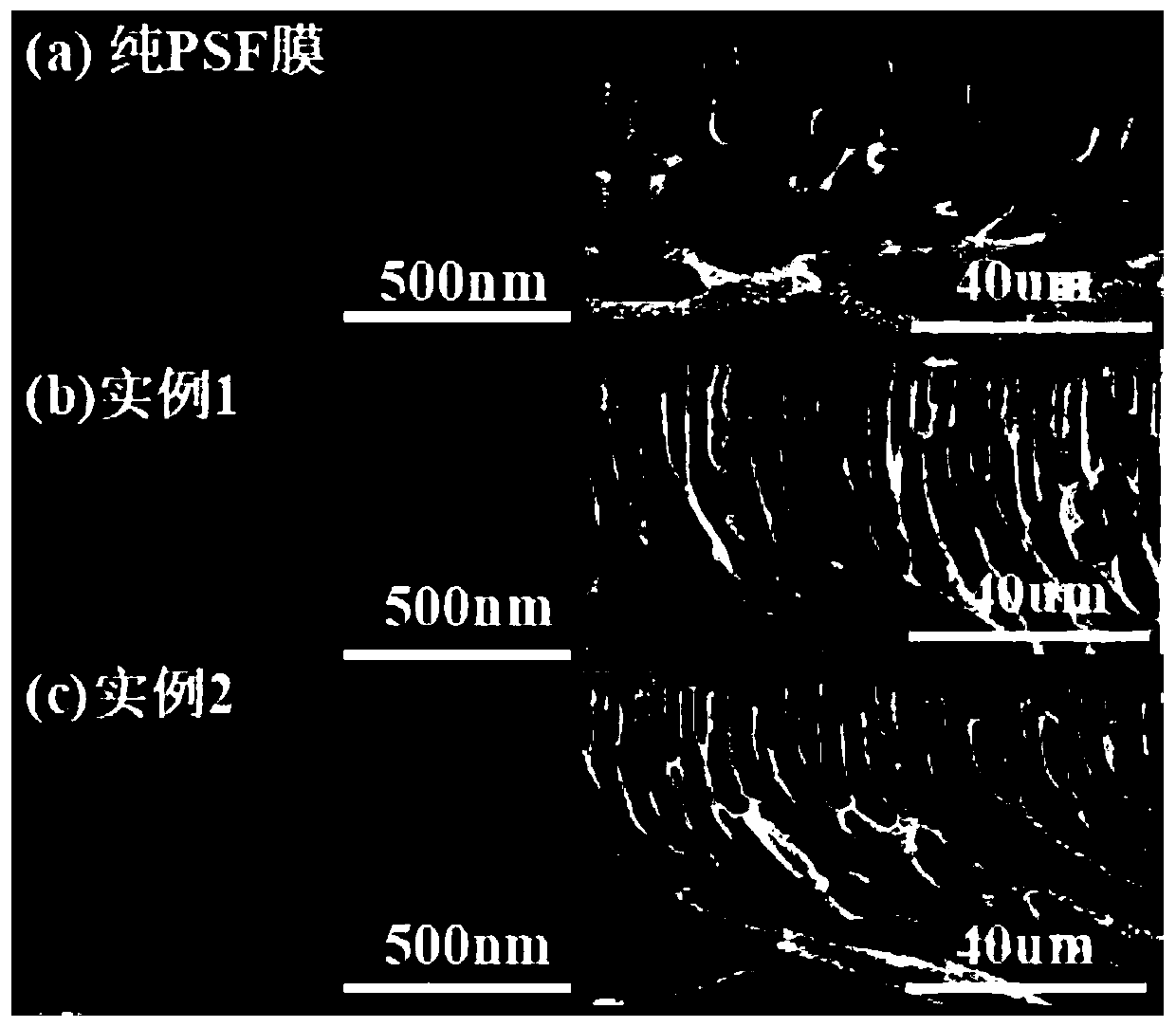

example 1

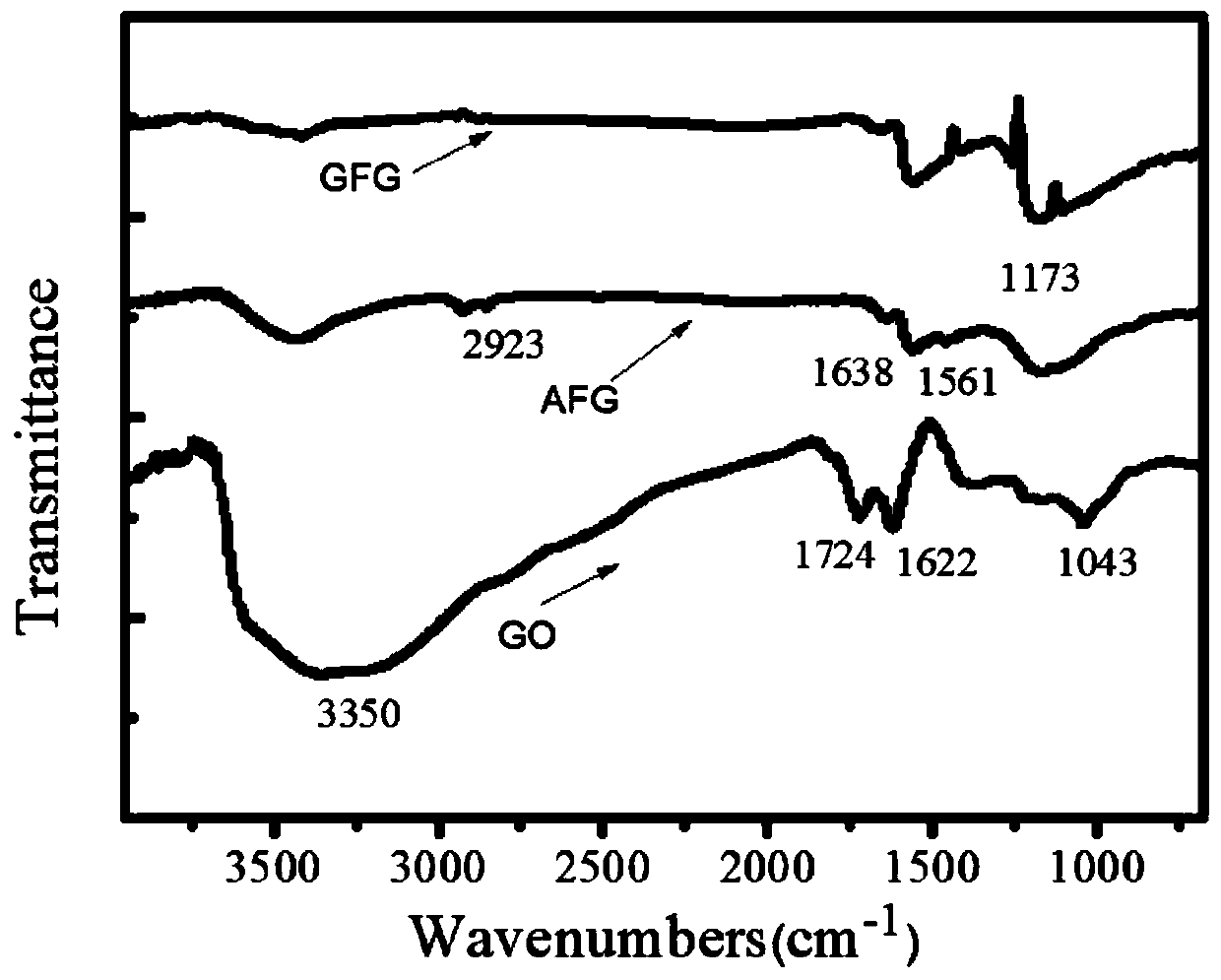

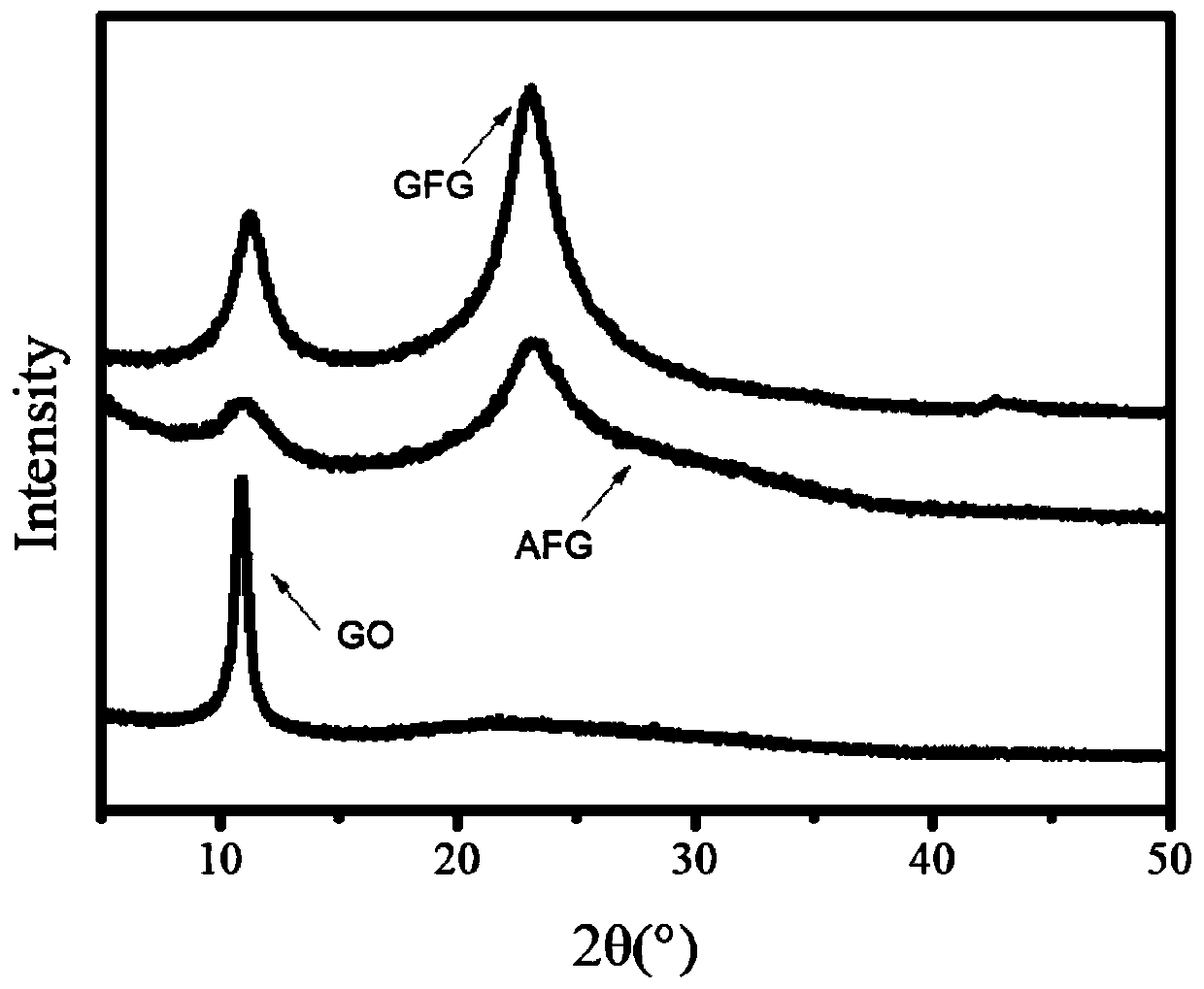

[0035] A kind of preparation method of guanidine functionalized graphene oxide / polysulfone ultrafiltration membrane is as follows:

[0036] (1) Preparation of AFG: 100mg GO, 40mL thionyl chloride and 2ml DMF were mixed in a flask. After sonication to fully disperse GO in the solvent, the mixture was stirred at 60 °C for 12 h. The acylated intermediate was separated by centrifugation, washed with dry DMF, and transferred directly to 25 mL of 1,6-hexanediamine heated to 45 °C. The mixture was stirred evenly at 50 °C, the product was washed with water several times, and then dried under vacuum at room temperature.

[0037] (2) Preparation of GFG: 50mg AFG, 3g OMIU and 50mL water were mixed in a flask so that the solution was uniformly dispersed, and then the pH of the solution was adjusted to 11 by NaOH aqueous solution. The mixture was stirred at 40 °C and quenched by adding 2 mL of TFA. After washing with water, the product was dried under vacuum at room temperature.

[003...

example 2

[0042] A kind of preparation method of guanidine functionalized graphene oxide / polysulfone ultrafiltration membrane is as follows:

[0043](1) Preparation of AFG: 150 mg GO, 30 mL thionyl chloride and 1 mL DMF were mixed in a flask. After sonication to fully disperse GO in the solvent, the mixture was stirred at 100 °C for 16 h. The acylated intermediate was separated by centrifugation, washed twice with dry DMF, and transferred directly to 35 mL of 1,6-hexanediamine heated to 40 °C. The mixture was stirred evenly at 40 °C, the product was washed with water several times, and then dried under vacuum at room temperature.

[0044] (2) Preparation of GFG: 10 mg AFG, 2 g OMIU and 30 mL water were mixed in a flask to make the solution uniformly dispersed, and then the pH of the solution was adjusted to 11 by NaOH aqueous solution. The mixture was stirred at 60 °C and quenched by adding 1 mL of TFA. After washing with water, the product was dried under vacuum at room temperature....

example 3

[0049] A kind of preparation method of guanidine functionalized graphene oxide / polysulfone ultrafiltration membrane is as follows:

[0050] (1) Preparation of AFG: 200 mg GO, 45 mL thionyl chloride and 5 mL DMF were mixed in a flask. After sonication to fully disperse GO in the solvent, the mixture was stirred at 80 °C for 30 h. The acylated intermediate was separated by centrifugation, washed twice with dry DMF, and transferred directly to 40 mL of 1,6-hexanediamine heated to 60 °C. The mixture was stirred evenly at 60 °C, the product was washed with water several times, and then dried under vacuum at room temperature.

[0051] (2) Preparation of GFG: 100 mg AFG, 4 g OMIU and 50 mL water were mixed in a flask so that the solution was uniformly dispersed, and then the pH of the solution was adjusted to 11 by NaOH aqueous solution. The mixture was stirred well at 60 °C and quenched by adding 5 mL of TFA. After washing with water, the product was dried under vacuum at room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com