Highland barley dough and preparation method thereof

A dough and highland barley technology, applied in the field of highland barley dough and its preparation, can solve the problems of high amylopectin content, rough taste, low gluten protein content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

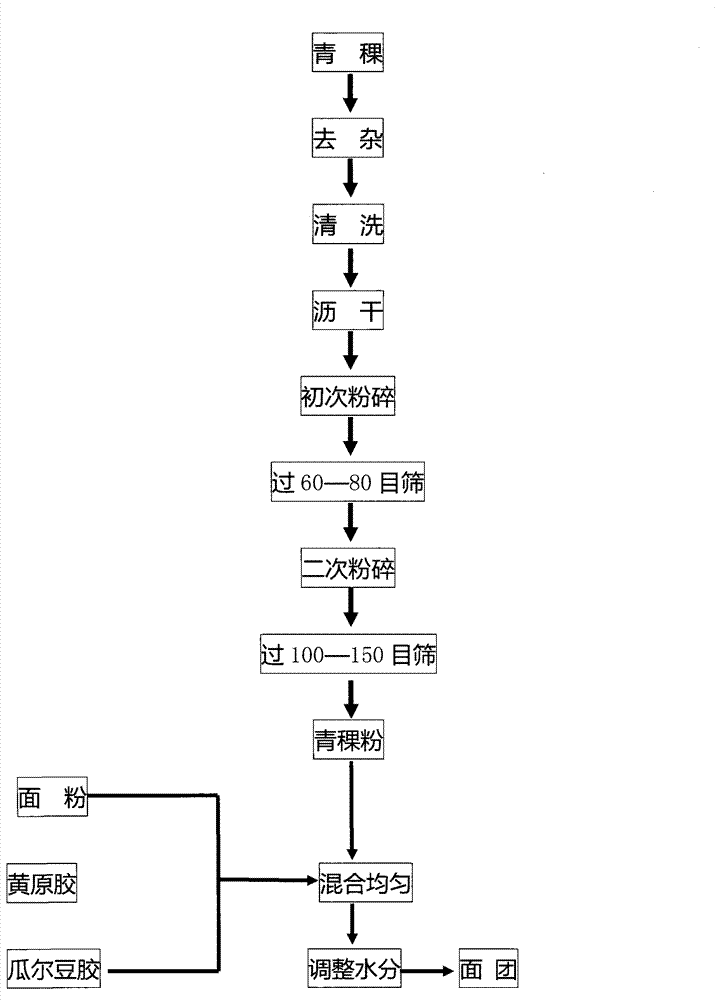

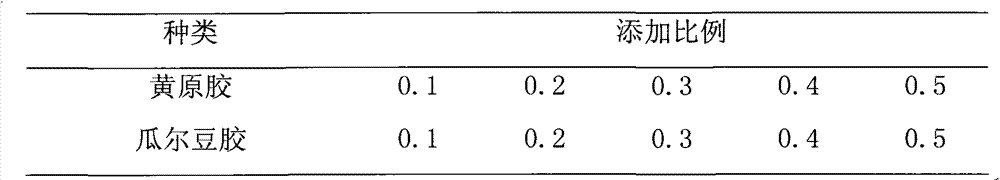

[0058] A kind of highland barley dough, the water content is 10-11%, the raw material ratio of this highland barley noodle powder is: highland barley powder 70kg, flour 29kg, xanthan gum 0.5kg, guar gum 0.5kg; After removing impurities from the wheat, it is peeled and ground into flour, and then sieved to obtain highland barley flour.

[0059] Its production method is:

[0060] (1) removing impurities, cleaning and draining the highland barley after sieving;

[0061] (2) naturally dry the dried highland barley, peel and grind it into powder, the peeling rate is 5%, and sieve with a 60-80 mesh sieve to get highland barley meal;

[0062] (3) Secondary superfine pulverization of the highland barley powder, passing through a 100-150 mesh sieve to obtain highland barley powder;

[0063] (4) Mix 70 kg of highland barley powder, 29 kg of flour, 0.5 kg of xanthan gum, and 0.5 kg of guar gum, add 10.5 liters of water, mix and stir evenly, and set aside.

Embodiment 2

[0065] A kind of highland barley dough, water content is 10-11%, the raw material ratio of this highland barley noodle powder is: highland barley powder 65.8kg, flour 34kg, xanthan gum 0.1kg, guar gum 0.1kg; After the impurities are removed from the highland barley, the barley is peeled and ground into powder, and then sieved to obtain highland barley powder.

[0066] Its production method is:

[0067] (1) removing impurities, cleaning and draining the highland barley after sieving;

[0068] (2) naturally dry the highland barley after draining, peel and grind the barley, the peeling rate is 6%, and sieve with a 60-80 mesh sieve to get the highland barley meal;

[0069] (3) Secondary superfine pulverization of the highland barley powder, passing through a 100-150 mesh sieve to obtain highland barley powder;

[0070] (4) Mix 65.8kg of highland barley powder, 34kg of flour, 0.1kg of xanthan gum, and 0.1kg of guar gum, add 11 liters of water, mix and stir evenly, and set aside. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com