High-specific-surface-area silver-loaded titanium dioxide composite antibacterial material and preparation method thereof

A compound antibacterial and high specific surface technology, applied in titanium dioxide, titanium oxide/hydroxide, medical science, etc., can solve the problems of high production cost, complex synthesis process, low specific surface area, etc., and achieve convenient operation and simple preparation process , broad-spectrum antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

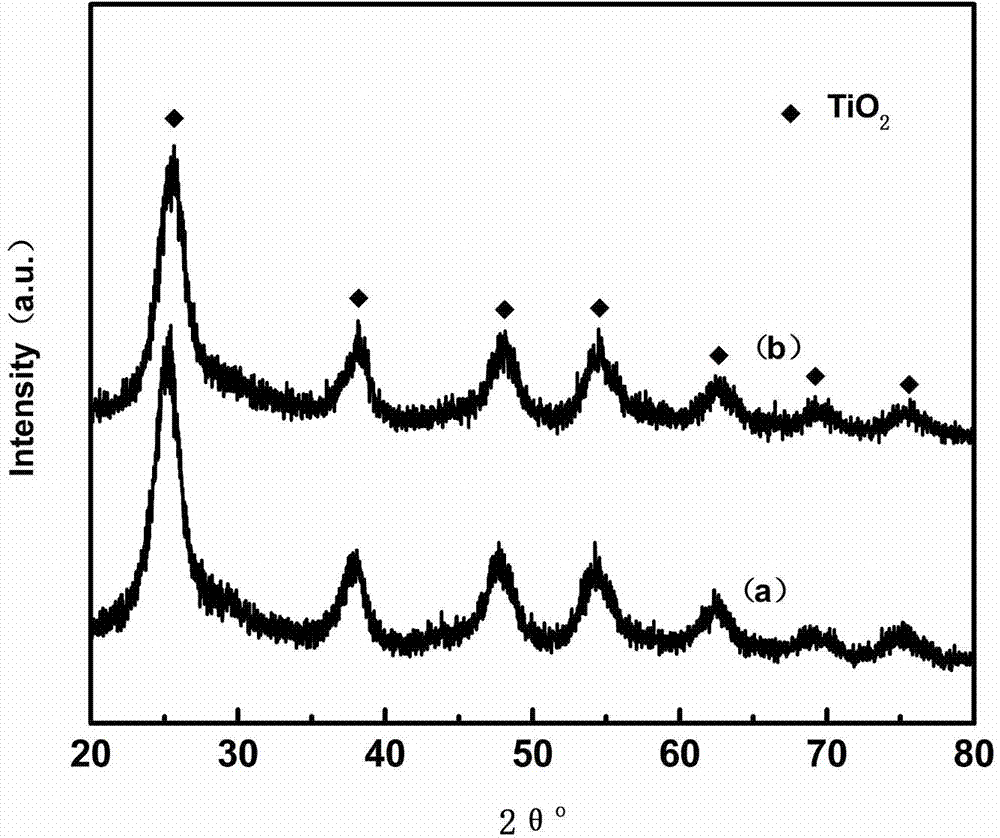

[0035] This embodiment is used to prepare TiO 2 Powder.

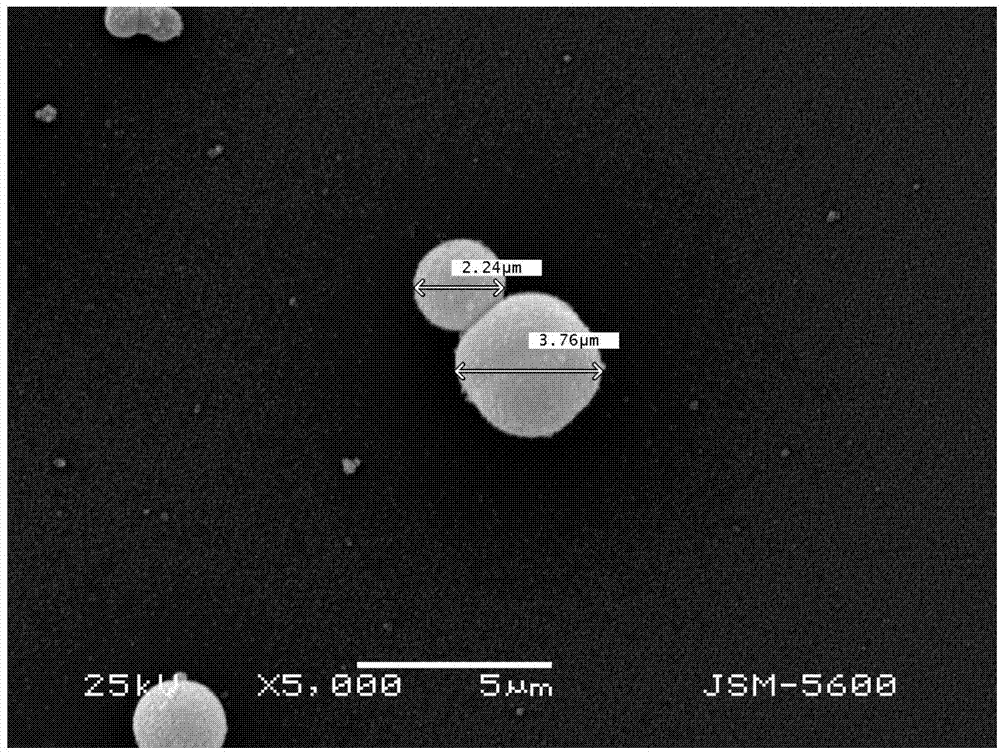

[0036] Dissolve the titanium source in distilled water 1 to obtain a titanium source aqueous solution; dissolve the pore-forming agent in distilled water 2 to obtain a pore-forming agent solution; mix the titanium source aqueous solution and pore-forming agent aqueous solution with a dispersant and a precipitating agent, stir for 10 minutes, and then In an oscillating water bath, react at 90r / min and 80°C for 4h, cool to room temperature, and filter with suction to obtain a crude product of antibacterial material; the crude product of antibacterial material is then washed with distilled water to remove precipitant, dispersant, pore-forming agent and Impurities, until the filtrate with BaCl 2 No precipitation was detected, and dried at 80°C for 4 hours to obtain TiO 2 Powder material sample A1.

[0037] The mass ratio of titanium source, distilled water 1, pore-forming agent, distilled water 2, dispersant and precipit...

Embodiment 2~4

[0039] A high specific surface Ag / TiO 2 The preparation method of composite antibacterial material comprises the following steps:

[0040] The reaction process is completed under dark conditions: dissolving the titanium source in distilled water 1 to obtain a titanium source aqueous solution, dissolving the silver source in distilled water 2 to obtain a silver source aqueous solution, dissolving the pore-forming agent in distilled water 3 to obtain a pore-forming agent aqueous solution; Titanium source aqueous solution, silver source aqueous solution, pore-forming agent aqueous solution, dispersant and precipitant are mixed and stirred for 20 minutes, then reacted in a shaking water bath for 5 hours at 100r / min and 90°C, cooled to room temperature and suction filtered to obtain a composite The crude product of antibacterial material; the crude product of composite antibacterial material is washed with distilled water to remove precipitant, dispersant, pore-forming agent and im...

Embodiment 5

[0054] This embodiment is used to illustrate the antibacterial performance of the composite antibacterial coating material provided by the present invention.

[0055] Adopt bacteriostatic zone test, according to "disinfection technical specification" (2002 version) 2.1.8.2 bacteriostatic zone test and Clinical Laboratory Standards Association (ClinicalandLaboratoryStandardsInstitute, CLSI) regulations utilize bacteriostatic agent to dissolve continuously to form different concentration gradients through agar diffusion, with show its antibacterial effect. This method is the TiO of embodiment 1 2 Powder A1 and Ag / TiO in Examples 2-4 2 Composite antibacterial materials A2-A4 were respectively dissolved in water and then adsorbed on filter paper with a diameter of 6 mm. Put the filter paper on an agar plate with a bacterial concentration of 38.5 CFU / mL, and after incubating at a constant temperature of 37°C for 18 hours, measure the diameter of the inhibition zone. The antibact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com