Hollow spherical rutile titanium dioxide mesocrystal and preparation method thereof

A rutile titanium dioxide, hollow spherical technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high energy consumption, poor environmental friendliness, and high industrialization cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Take 3 mL of nitric acid with a mass percentage of 63% and add it to 50 mL of a 10% hydrogen peroxide solution;

[0026] 2) Add potassium titanium oxalate to the solution obtained in step 1), so that the concentration of potassium titanium oxalate in the solution is 100 mmol / L, and mix thoroughly by ultrasonic oscillation to obtain a dark red transparent solution;

[0027] 3) Seal the dark red transparent solution obtained in step 2) and place it at 80 o C oven, keep warm for 72 hours, centrifuge, wash and dry to obtain white powder, which is hollow spherical rutile titanium dioxide mesocrystal.

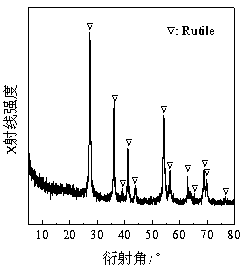

[0028] The hollow spherical rutile titanium dioxide mesocrystal prepared in this example is as follows figure 1 , 2 As shown, the width of the nanorods is about 100-250 nm, the length is about 200-500 nm, and the diameter of the hollow sphere assembled by the nanorods is 3.0-6.0 μm. image 3 The XRD results confirmed that the obtained powder was well-crystallized rutile ...

Embodiment 2

[0031] 1) Take 1 mL of nitric acid with a mass percentage of 63% and add it to 50 mL of a 10% hydrogen peroxide solution;

[0032] 2) Add potassium titanium oxalate to the solution obtained in step 1), so that the concentration of potassium titanium oxalate in the solution is 100 mmol / L, and mix thoroughly by ultrasonic oscillation to obtain a dark red transparent solution;

[0033] 3) Seal the dark red transparent solution obtained in step 2) and place it at 80 o C oven, heat preservation for 72 hours, centrifuged, washed, dried to obtain a white powder.

[0034] The SEM photograph of the hollow spherical rutile titanium dioxide mesocrystal that this example makes is as follows Figure 13 , the structural unit nanorods have a length of 150-250 nm and a width of 70-150 nm.

Embodiment 3

[0036] 1) Take 3 mL of nitric acid with a mass percentage of 63% and add it to 50 mL of a 10% hydrogen peroxide solution;

[0037] 2) Add potassium titanium oxalate to the solution obtained in step 1) so that the concentration of potassium titanium oxalate in the solution is 200 mmol / L, and mix thoroughly by ultrasonic oscillation to obtain a dark red transparent solution;

[0038] 3) Seal the dark red transparent solution obtained in step 2) and place it at 80 o C oven, heat preservation for 72 hours, centrifuged, washed, dried to obtain a white powder.

[0039] The SEM photograph of the hollow spherical rutile titanium dioxide mesocrystal that this example makes is as follows Figure 14 , the length of the structural unit nanorod is about 150-200 nm, and the width is about 50-100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com